Novel negative electrode material of sodium ion battery as well as preparation and application thereof

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low Coulomb efficiency in the first cycle, low material specific capacity, large volume expansion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

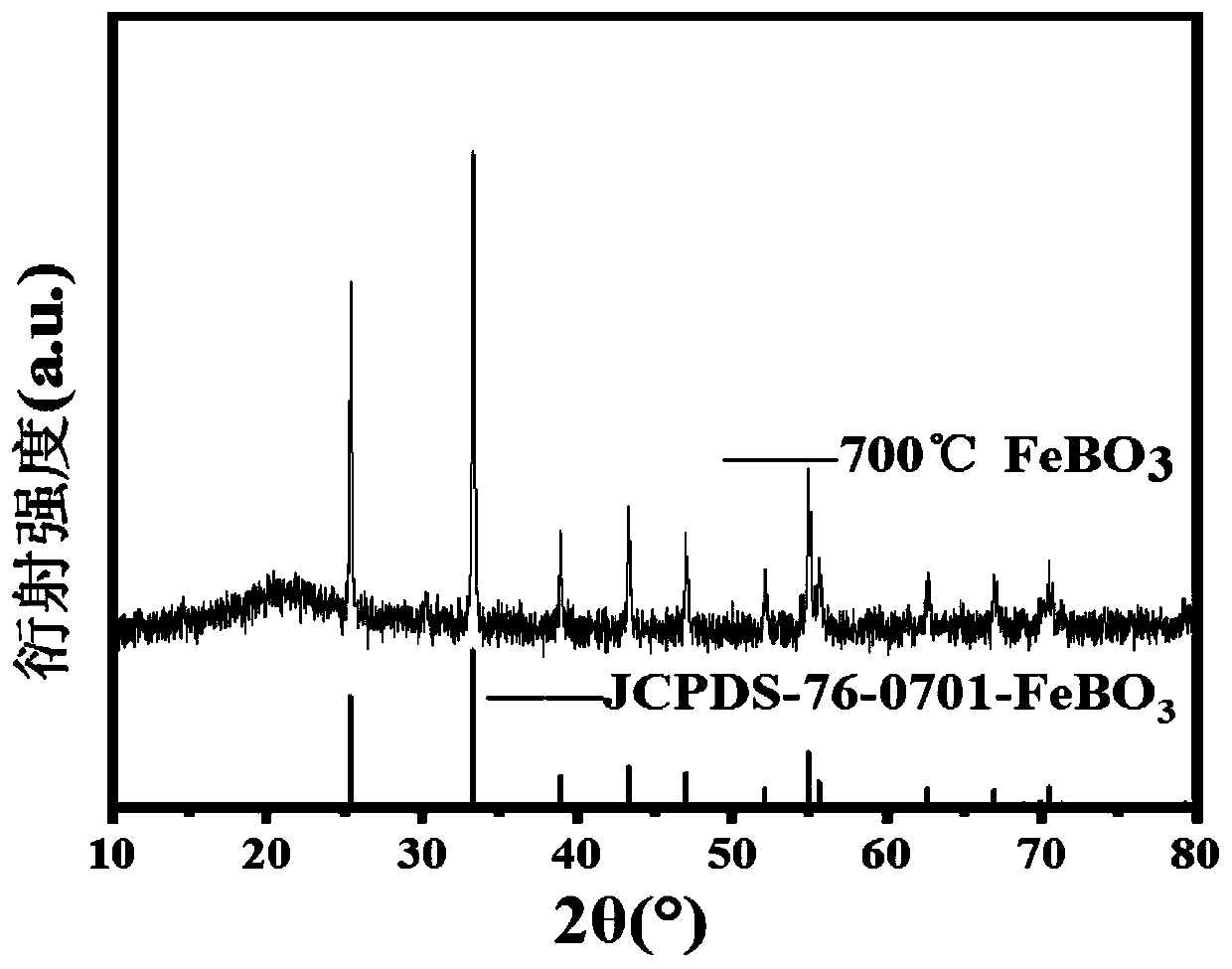

Embodiment 1

[0033] 4.5g FeC 2 o 4 2H 2 O and 2.0 g H 3 BO 3 Add appropriate amount of deionization and alcohol to the mortar while grinding to make the grinding fully. The grinding time should be more than 2 hours. After grinding, it should be less than 300 meshes. The material is placed in a corundum crucible, air is passed into the tube furnace at a flow rate of 150ml / min, and the material is placed in the tube furnace at a rate of 5 °C / min to 700 °C for sintering for 10 hours, and then cooled naturally for 100 After washing three times with deionized water at ℃, excess boron oxide was removed, and then the obtained product was dried in an oven at 80 ℃ for 24 hours to obtain FeBO 3 Material.

Embodiment 2

[0035] 2.25g FeC 2 o 4 2H 2 O and 1.87 g NH 4 HB 4 o 7 ·3H 2 O is added into the mortar and ground thoroughly, and the grinding steps and drying process are the same as in Example 1. Air is passed into the tube furnace at a flow rate of 200ml / min and the material is placed in the tube furnace to rise to Sintered at 650°C for 12h, then cooled naturally, washed three times with deionized water at 90°C, and dried in an oven at 90°C for 24h to obtain FeBO 3 Material.

Embodiment 3

[0037] 9.66g C 4 h 6 o 4 Fe and 2.3g B 2 o 3 Add in the mortar and grind fully, the grinding steps and drying process are the same as in Example 1, and the air is passed into the tube furnace at a flow rate of 120ml / min and the material is placed in the tube furnace to rise to 700°C at a heating rate of 4°C / min. ℃ sintering for 9 hours, then naturally cooled, washed three times with deionized water at 100 ℃, and dried in an oven at 100 ℃ for 24 hours to obtain FeBO 3 Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com