Preparation method of low-sulfur compact crystal form cobalt carbonate

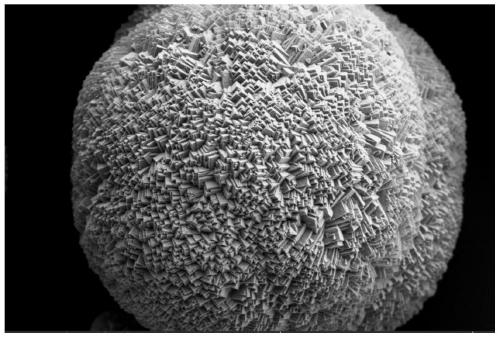

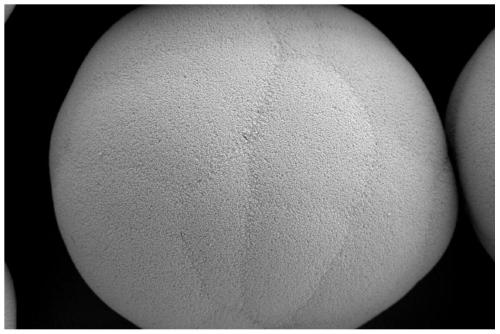

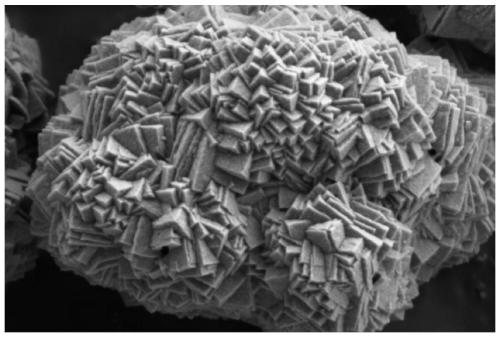

A cobalt carbonate and cobalt sulfate solution technology, which is applied in the direction of cobalt carbonate, can solve the problems of production efficiency and other problems, and achieve the effect of dense crystal form and low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1. Preparation of solutions: prepare a cobalt sulfate solution with a concentration of 1.2 mol / L, and prepare an ammonium bicarbonate solution with a concentration of 2.5 mol / L.

[0029] Step 2. Synthesis of seed crystals: inject the ammonium bicarbonate solution prepared in step 1 into the reactor as the bottom liquid, the volume of the bottom liquid accounts for 0.06% of the reactor, and the pH value of the bottom liquid is controlled to 8.3; 1. The prepared cobalt sulfate solution was pumped into the reaction kettle separately, the feeding time was 2 hours, the feeding flow rate was 20mL / min, the synthesis temperature was 38°C, and the final pH range was 7.9, and cobalt carbonate seeds were synthesized with a particle size of 2.5 μm;

[0030] Step 3. Growth and synthesis: the above-mentioned cobalt carbonate seed crystals are placed in the reactor to continue to grow, the stirring speed is 280rpm, the corresponding cobalt liquid flow rate of the 50L reactor is 10...

Embodiment 2

[0037] Step 1. Prepare the solution: prepare an aluminum-doped cobalt sulfate solution with a concentration of 2.2 mol / L, wherein the mass ratio of aluminum element to cobalt element in the cobalt liquid is 0.0125, and prepare an ammonium bicarbonate solution with a concentration of 2.9 mol / L.

[0038] Step 2, synthesis of seed crystals: inject the ammonium bicarbonate solution prepared in step 1 into the reactor as the bottom liquid, the volume of the bottom liquid accounts for 0.20% of the reactor, and the pH value of the bottom liquid is controlled to be 8.6; The cobalt sulfate solution prepared in step 1 was pumped into the reaction kettle separately, the feeding time was 2 hours, the feeding flow rate was 25mL / min, the synthesis temperature was 42°C, and the final pH range was 7.8, and cobalt carbonate seeds were synthesized with a particle size of 1.5 μm;

[0039] Step 3. Growth and synthesis: the above-mentioned cobalt carbonate seed crystals are placed in the reactor to...

Embodiment 3

[0047] Step 1, preparing the solution: preparing the cobalt sulfate solution with a concentration of 1.8 mol / L, and preparing the ammonium bicarbonate solution with a concentration of 2.8 mol / L.

[0048] Step 2, synthesis of seed crystals: inject the ammonium bicarbonate solution prepared in step 1 into the reactor as the bottom liquid, the volume of the bottom liquid accounts for 0.1% of the reactor, and the pH value of the bottom liquid is controlled to be 8.4; The cobalt sulfate solution prepared in step 1 was pumped into the reaction kettle separately, the feeding time was 2 hours, the feeding flow rate was 25mL / min, the synthesis temperature was 40°C, and the final pH range was 8.2, and cobalt carbonate seeds were synthesized with a particle size of 2.5 μm;

[0049] Step 3. Growth and synthesis: the above-mentioned cobalt carbonate seed crystals are placed in the reactor to continue to grow, the stirring speed is 300rpm, the corresponding cobalt liquid flow rate of the 50L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com