Whisker toughened and reinforced geopolymer and preparation method thereof

A geopolymer and whisker technology, applied in the field of whisker toughened and reinforced geopolymers, to achieve good economic and environmental benefits, improve surface energy, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

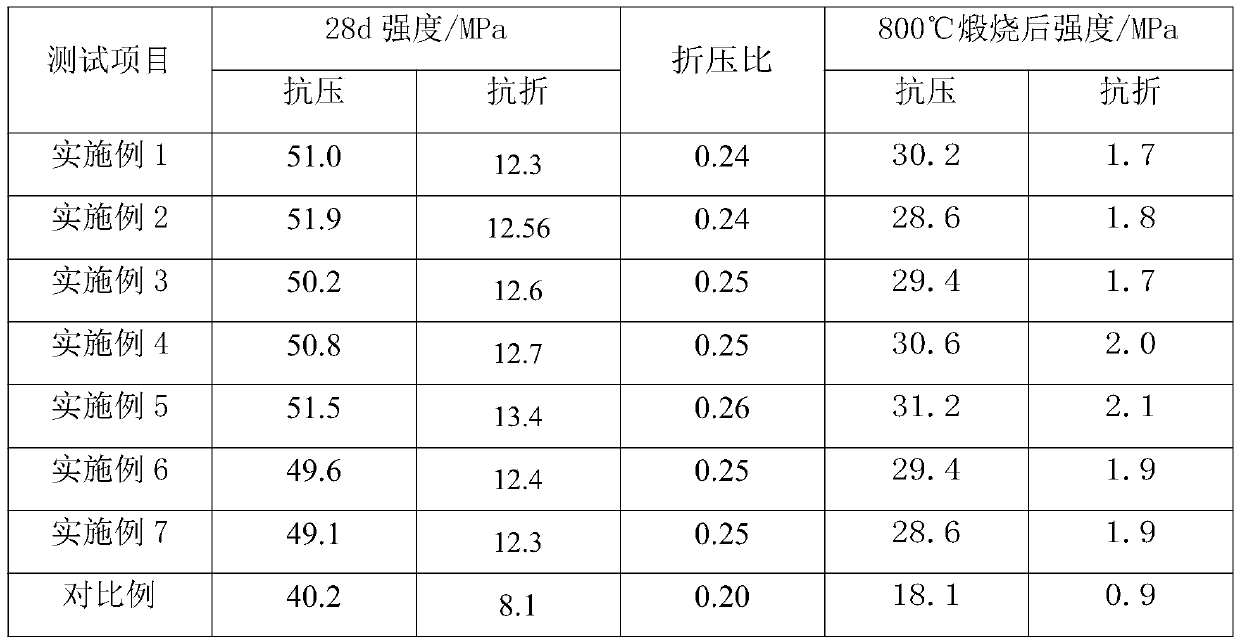

Examples

Embodiment 1

[0015] A whisker-toughened and reinforced polymer, prepared from the following raw materials in parts by weight: 100 parts of silicon-aluminum raw materials (metakaolin: fly ash=2:1, weight ratio), 80 parts of activator (sodium hydroxide and water glass with a modulus of 3.3 in a weight ratio of 1:4), whisker (potassium titanate whisker) 1 part, dispersant (calcium lignosulfonate) 0.3 part.

[0016] The preparation method of whisker-toughened and reinforced geopolymer: Add whiskers and dispersant to the activator, mechanically stir for 15 minutes, and then ultrasonically disperse for 30 minutes to obtain a suspension; add silicon-aluminum raw materials to the suspension, 50r / After stirring for 1 minute at a speed of 200r / min, stir for 3 minutes at a speed of 200r / min to obtain a slurry, inject the slurry into a mold for molding, and then maintain it at 25°C and a relative humidity of 90% for 24 hours, demould, continue Curing for 28 days under the conditions of 25°C and 90% r...

Embodiment 2

[0018] A whisker-toughened polymer is prepared from the following raw materials in parts by weight: 100 parts of silicon-aluminum raw materials (metakaolin: fly ash=2:1), 80 parts of activator (sodium hydroxide and modulus Water glass weight ratio of 3.3 is a mixture of 1:4), whiskers (potassium titanate whiskers) 4 parts, dispersant (sodium dodecylsulfonate) 0.1 parts.

[0019] The preparation method of the whisker-toughened polymer is the same as that in Example 1.

Embodiment 3

[0021] A whisker-toughened polymer is prepared from the following raw materials in parts by weight: 100 parts of silicon-aluminum raw materials (metakaolin: fly ash=2:1), 80 parts of activator (sodium hydroxide and modulus Water glass weight ratio of 3.3 is a mixture of 1:4), whiskers (potassium titanate whiskers) 6 parts, dispersant (sodium dodecylsulfonate) 0.15 parts.

[0022] The preparation method of the whisker-toughened polymer is the same as that in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com