Garden waste-based organic-inorganic composite fire-free lightweight glazed material and preparation method

A technology of garden waste and inorganic compounding, applied in the field of garden waste-based organic-inorganic composite non-fired light-weight glazed materials and its preparation, can solve the problem of difficulty in forming industrialized and large-scale production capacity, poor efficiency, and garden waste resources. Problems such as the difficulty of resiliency, to reduce production costs and difficulty of resourcing, improve wear resistance, and facilitate production deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

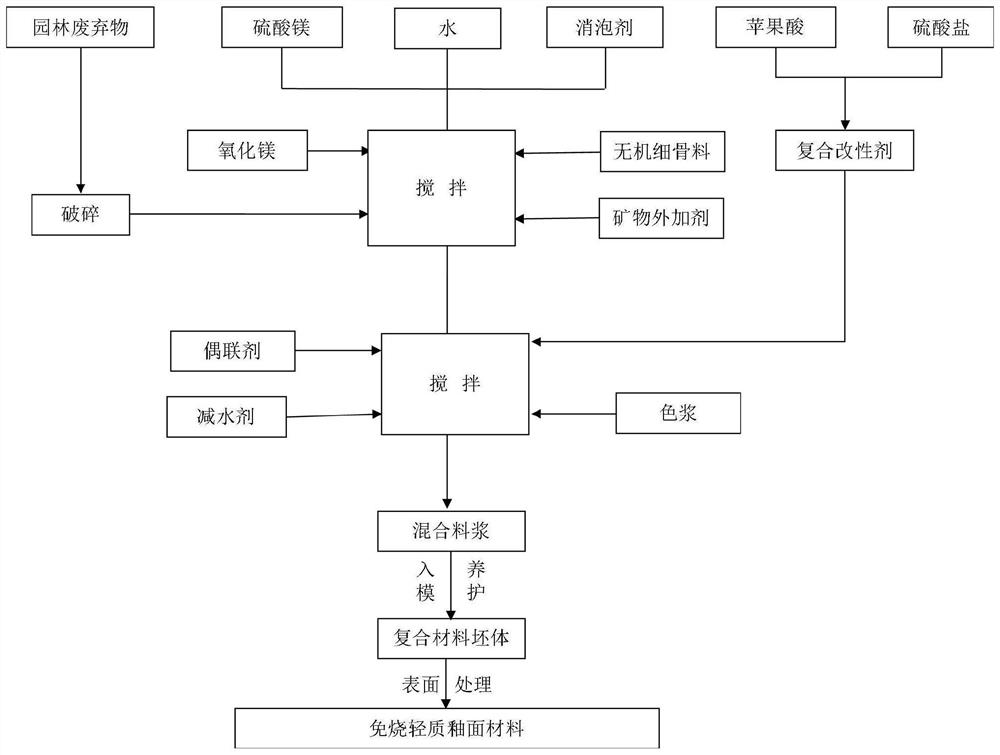

Method used

Image

Examples

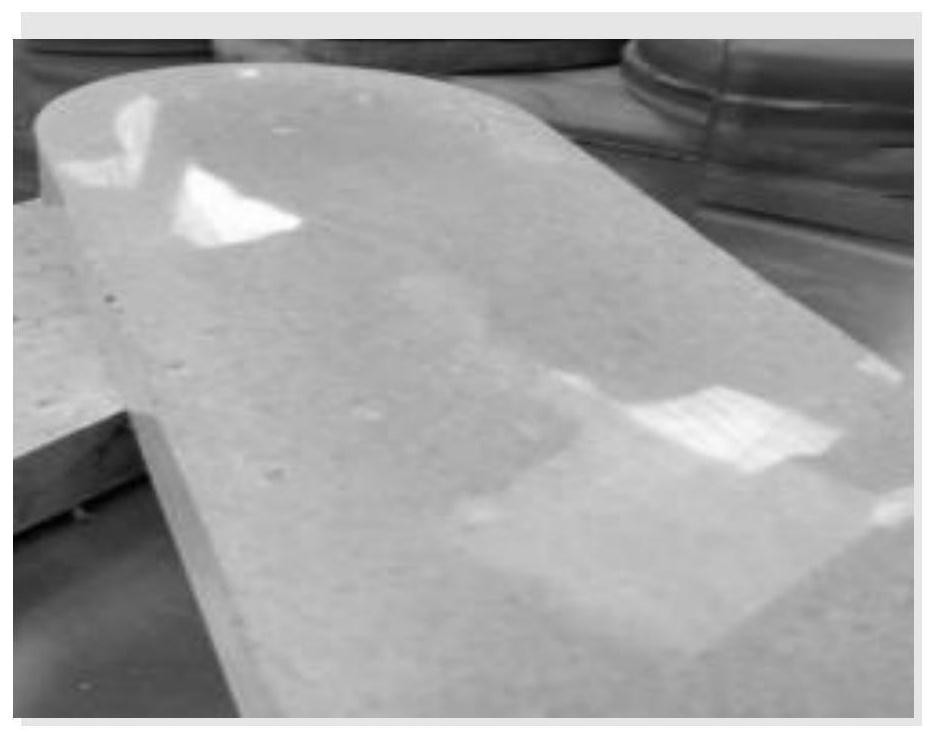

Embodiment 1

[0042] A garden waste-based organic-inorganic composite fire-free light glaze material, the raw materials of which include: garden waste, aeolian sand, fly ash, lightly burned magnesium oxide, magnesium sulfate, polyoxyethylene polyoxypropanolamine Ether, polycarboxylate water reducer, composite modifier, silane coupling agent KH570, water-based color paste, varnish, water. Among them, the particle size of garden waste is less than 4mm. The weight ratio of light-burned magnesia to garden waste is 0.8:1. The weight ratio of aeolian sand to garden waste is 1:4. The amount of fly ash is 10wt% of light-burned magnesium oxide. The active magnesia content in the light-burned magnesia is 50wt%. The molar ratio of active magnesium oxide to magnesium sulfate in light-burned magnesium oxide is 7:1. The consumption of polyoxyethylene polyoxypropanolamine ether is 0.1wt% of magnesium sulfate. The amount of polycarboxylate water reducer is 1 wt% of the total amount of raw materials. ...

Embodiment 2

[0052] A garden waste-based organic-inorganic composite non-fired light glaze material, the raw materials of which include: garden waste, medium and fine sand, slag powder, light-burned magnesium oxide, magnesium sulfate, emulsified silicone oil, polycarboxylic acid water reducing agent, composite modifier, silane coupling agent KH570, water-based color paste, enamel paint, water. Among them, the particle size of garden waste is less than 4mm. The weight ratio of light-burned magnesia to garden waste is 1:1. The weight ratio of medium and fine sand to garden waste is 1:3. The amount of slag powder is 15wt% of light-burned magnesia. The active magnesia content in the light-burned magnesia is 60wt%. The molar ratio of active magnesium oxide to magnesium sulfate in light-burned magnesium oxide is 7:1. The consumption of emulsified silicone oil is 0.2wt% of magnesium sulfate. The amount of polycarboxylate water reducer is 0.8wt% of the total amount of raw materials. The comp...

Embodiment 3

[0062] The weight ratio of light-burned magnesia to garden waste is 1.2:1. The amount of slag powder is 20wt% of light-burned magnesium oxide. The active magnesia content in the light-burned magnesia is 65wt%. The consumption of emulsified silicone oil is 0.3wt% of magnesium sulfate. The amount of polycarboxylate water reducer is 0.5wt% of the total amount of raw materials. The dosage of the composite modifier is 1.5wt% of the active magnesia content in the light-burned magnesia. The consumption of the water-based color paste is 3wt% of the garden waste. The amount of enamel paint is 8wt% of the raw material amount. The total consumption of water is 90wt% of the raw material consumption. The composition and dosage of the remaining raw materials and the preparation method of the glaze material are the same as in Example 2.

[0063] It was made into a test block of 40*40*160mm for strength test, its 28d flexural strength was 12.46MPa, 28d compressive strength was 28.89MPa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com