Method for rapidly preparing multi-dimensional fluorescent nanoparticles and quantitatively characterizing dynamic dispersion state of multi-dimensional fluorescent nanoparticles in situ

A fluorescent nanoparticle, dispersed state technology, used in fluorescence/phosphorescence, material analysis by optical means, measurement devices, etc., can solve the problem of difficulty in accurately distinguishing multidimensional fluorescent nanoparticle dispersion states, inability to monitor the evolution process, and lack of universality. Representation and other issues, to achieve the effect of fast test speed, reduced preparation difficulty, and enhanced curing uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

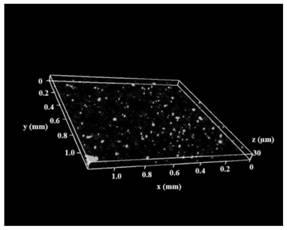

Image

Examples

Embodiment 1

[0023] Multi-dimensional nanoparticles choose SiO 2 Nanoparticles and carbon nanotubes, fluoresceins with aggregation-induced luminescent properties are selected from tetraphenylethylene-rhodamine B and tetraphenylethylene-fluorescein isothiocyanate, and onium salt cationic light containing long-chain alkyl or alkoxy groups The initiator is [4-(2-hydroxy-3-butoxy-1-propoxy)]phenylphenyliodonium-iodonium hexafluoroantimonate. In dark room conditions, anhydrous ethanol, SiO 2 The two systems of nanoparticles, tetraphenylethylene-rhodamine B and absolute ethanol, carbon nanotubes, tetraphenylethylene-fluorescein isothiocyanate were ultrasonically stirred uniformly according to the ratio of parts by mass of 100:0.2:0.01. Wherein the ultrasonic power is 80kW, the stirring speed is 400r / min, and the time is 1h. After mixing evenly, the precursor solution was poured into an opaque tetrafluoro round-bottomed flask, which was placed in a closed microwave reactor with a tetrafluoro st...

Embodiment 2

[0027] Multi-dimensional nanoparticles choose SiO 2 Nanoparticles and graphene oxide, fluorescein with aggregation-induced luminescent properties are selected from tetraphenylethylene-rhodamine B and tetraphenylethylene-7-amino-4-methylcoumarin, containing long-chain alkyl or alkoxy [4-(2-hydroxyl-3-allyloxyl-1-propoxyl)]phenylphenyliodonium-hexafluoroarsenic acid iodonium salt is used as the onium salt cationic photoinitiator. In dark room conditions, anhydrous ethanol, SiO 2 Nanoparticles, tetraphenylethylene-rhodamine B and absolute ethanol, graphene oxide, tetraphenylethylene-7-amino-4-methylcoumarin two-group system, the ratio of parts by mass is 100:1:0.05 Separately ultrasonically stir well. The ultrasonic power is 120kW, the stirring speed is 800r / min, and the time is 1.5h. After mixing evenly, the precursor solution was poured into an opaque tetrafluoro round-bottomed flask, which was placed in a closed microwave reactor with a tetrafluoro stirring device, and the ...

Embodiment 3

[0031]Multi-dimensional nanoparticles are selected from carbon nanotubes and graphene oxide, and the fluoresceins with aggregation-induced luminescent properties are selected from tetraphenylethylene-fluorescein isothiocyanate and tetraphenylethylene-7-amino-4-methylcoumarin, containing Long-chain alkyl or alkoxy onium salt cationic photoinitiator adopts [4-(2-hydroxy-3-alkoxy-1-propoxy)]phenylphenyliodonium-iodonium hexafluorophosphate . Under dark room conditions, two groups of absolute ethanol, carbon nanotubes, tetraphenylethylene-fluorescein isothiocyanate and absolute ethanol, graphene oxide, tetraphenylethylene-7-amino-4-methylcoumarin According to the ratio of parts by mass of 100:0.5:0.02, ultrasonically stir them evenly. The ultrasonic power is 100kW, the stirring speed is 600r / min, and the time is 2h. After mixing evenly, the precursor solution was poured into an opaque tetrafluoro round-bottomed flask, which was placed in a closed microwave reactor with a tetrafl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com