Preparation method of perovskite thin film and cell added with triiodide and cell

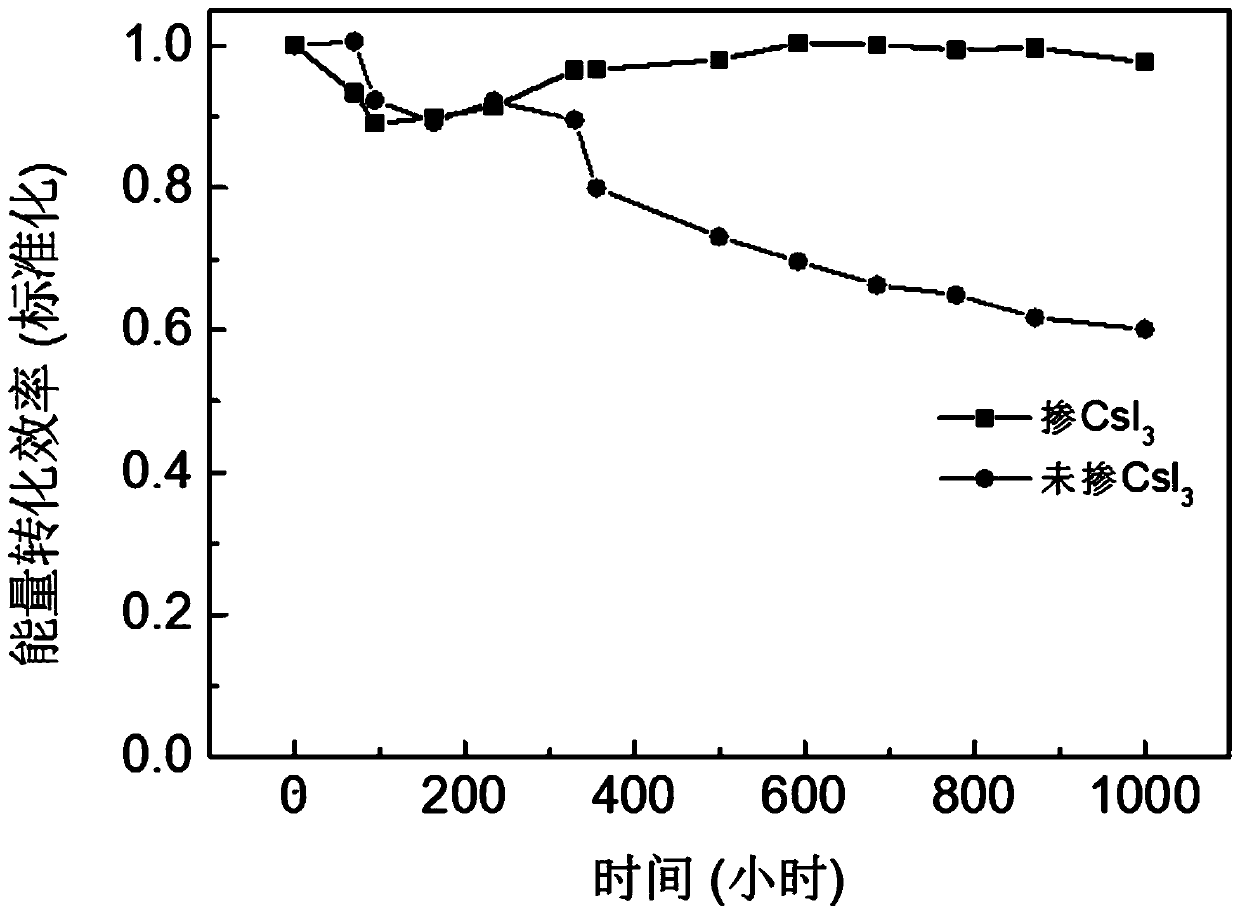

A technology of triiodide and perovskite, which can be used in circuits, photovoltaic power generation, electrical components, etc., and can solve problems such as crystal quality degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The invention discloses a method for preparing a perovskite film added with triiodide, which is referred to as a one-step solution method for short, and includes the following steps:

[0066] Step 1. Combine the two precursors BX of perovskite 2 And AX and triiodide MI 3 They are added to an organic solvent and mixed to obtain a triiodide-containing perovskite precursor solution.

[0067] Step 2: Apply the perovskite precursor solution prepared in step 1 to the surface of the substrate on which the transmission layer has been prepared by any one of spin coating, knife coating, slit continuous coating, and spray coating to obtain triiodine-containing Ionic metal halide perovskite film layer.

[0068] Step three: treating and annealing the metal halide perovskite film layer of step two with an anti-solvent to obtain a uniform and flat perovskite film containing triiodide ions. among them,

[0069] B is at least one of +2 metal or non-metal ions or groups, including lead, tin, tu...

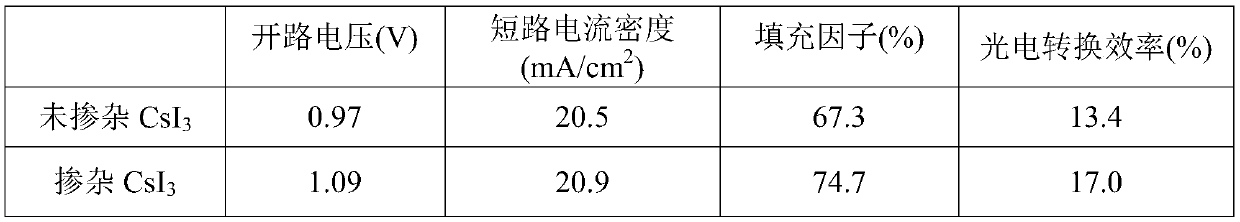

Embodiment 1

[0094] The first method of the present invention for preparing a battery containing a perovskite film added with triiodide as described above-a one-step solution method, includes the following steps:

[0095] (11) The ITO transparent conductive glass was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then used N 2 After drying, treat with UV O-zone for 10 minutes.

[0096] (12) Preparation of TiO on ITO 2 The electron transport layer is sprayed with a thickness of 20nm.

[0097] (13) One-step preparation of perovskite film doped with triiodide ion: 461 mg of PbI 2 (1mmol), 172mg formamidine hydroiodide (1mmol), 5.14mg CsI 3 (0.01mmol) was dissolved in 1mL of DMF solution, and 96uL of anhydrous N-methylpyrrolidone was added, heated and stirred at 60°C for 4h, after the mixing was complete, the perovskite film layer doped with triiodide ions was prepared by knife coating method. Chlorobenzene was quickly and uniformly coated on the ...

Embodiment 2

[0101] The second method of the present invention for preparing a battery containing a perovskite film added with triiodide as described above-a two-step solution method, includes the following steps:

[0102] (21) The ITO transparent conductive glass was ultrasonically cleaned with detergent, deionized water, acetone, and isopropanol for 30 minutes, and then used N 2 After drying, treat with UV O-zone for 10 minutes.

[0103] (22) Preparation of SnO on ITO 2 The electron transport layer adopts a slit coating method with a thickness of 30nm.

[0104] (23) Two-step method to prepare perovskite film doped with triiodide ion: add 414.9mg of PbI 2 (0.9mmol), 36.7mg of PbBr 2 (0.1mmol), 4.66mg of RbI 3 (0.01mmol) was dissolved in 1mL DMF solution, and 96uL of anhydrous N-methylpyrrolidone was added, heated and stirred at 55℃ for 4h, after the mixing was completed, the perovskite precursor doped with triiodide ions was prepared by slit coating method Thin film layer, thickness 250nm.

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com