Biomechanical mandible scaffold and preparation method of micro-nano hierarchical permeable titanium-niobium surface

A mandibular and permeability technology, applied in pharmaceutical formulations, tissue regeneration, drug delivery, etc., can solve the problems of easy deformation, high absorption rate of free non-vascularized cancellous bone, insufficient stress of transplanted bone, etc. Excellent performance and biocompatibility, excellent surface osteogenic activity, and the effect of facilitating the adhesion of osteoblasts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

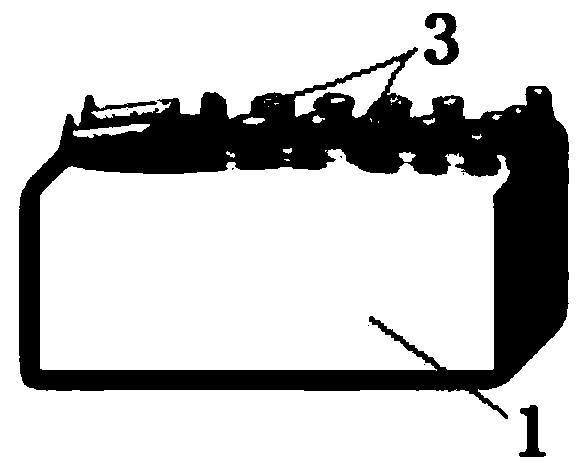

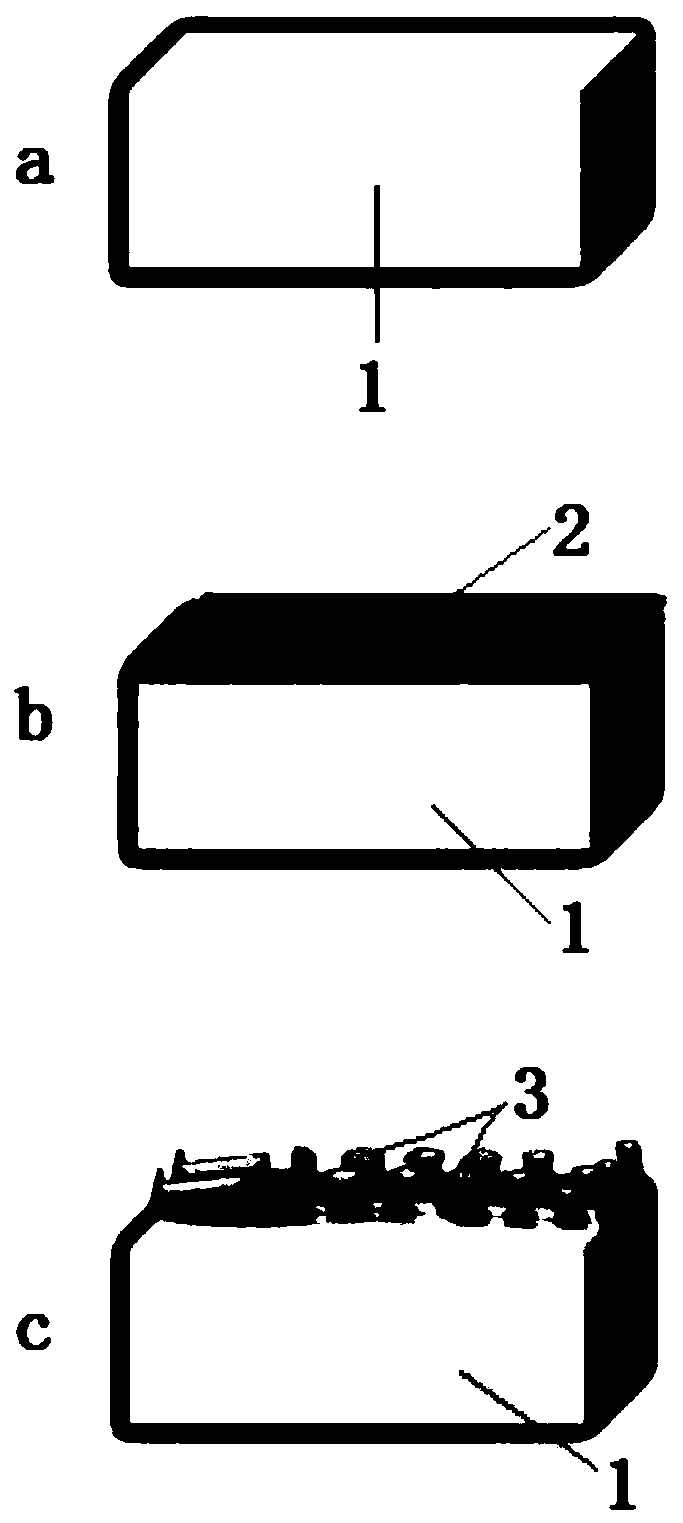

[0036] refer to figure 1 , the present embodiment provides a biomechanical mandibular bracket, the material of the mandibular bracket is a gradient structure, including an alloy matrix and a porous surface; the alloy matrix is a Ti-Nb-based β-series alloy material; the porous The surface is titanium-niobium surface with micro-nano graded permeability. The alloy matrix further includes at least one of tin (Sn) and zirconium (Zr). The range of pore diameters in the titanium-niobium surface with micro-nano graded permeability is 100-300 nanometers. The thickness of the porous surface is 5-30 microns.

Embodiment 2

[0038] refer to figure 1 , the present embodiment provides a biomechanical mandibular bracket, the material of the mandibular bracket is a gradient structure, including an alloy matrix and a porous surface; the alloy matrix is a Ti-Nb-based β-series alloy material; the porous The surface is titanium-niobium surface with micro-nano graded permeability. The alloy matrix also includes tin (Sn) and zirconium (Zr). The range of pore diameters in the titanium-niobium surface with micro-nano graded permeability is 100-300 nanometers.

[0039] refer to figure 2 , the present embodiment also provides a method for preparing a titanium-niobium surface with micro-nano graded permeability on the surface of the alloy substrate of the mandibular bracket, comprising the following steps: an alloy coating is deposited on the surface of the alloy substrate of the mandibular bracket, By de-alloying the alloy coating, a titanium-niobium surface with micro-nano grade permeability can be prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com