High-purity gold powder clean production method

A production method and clean production technology, applied in the direction of metal processing equipment, process efficiency improvement, electrolysis process, etc., can solve the problems of inability to meet quality requirements, discharge waste water and waste gas, and high treatment costs, and save investment in environmental protection facilities and three waste treatment. The effect of cost, simple process and fast melting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

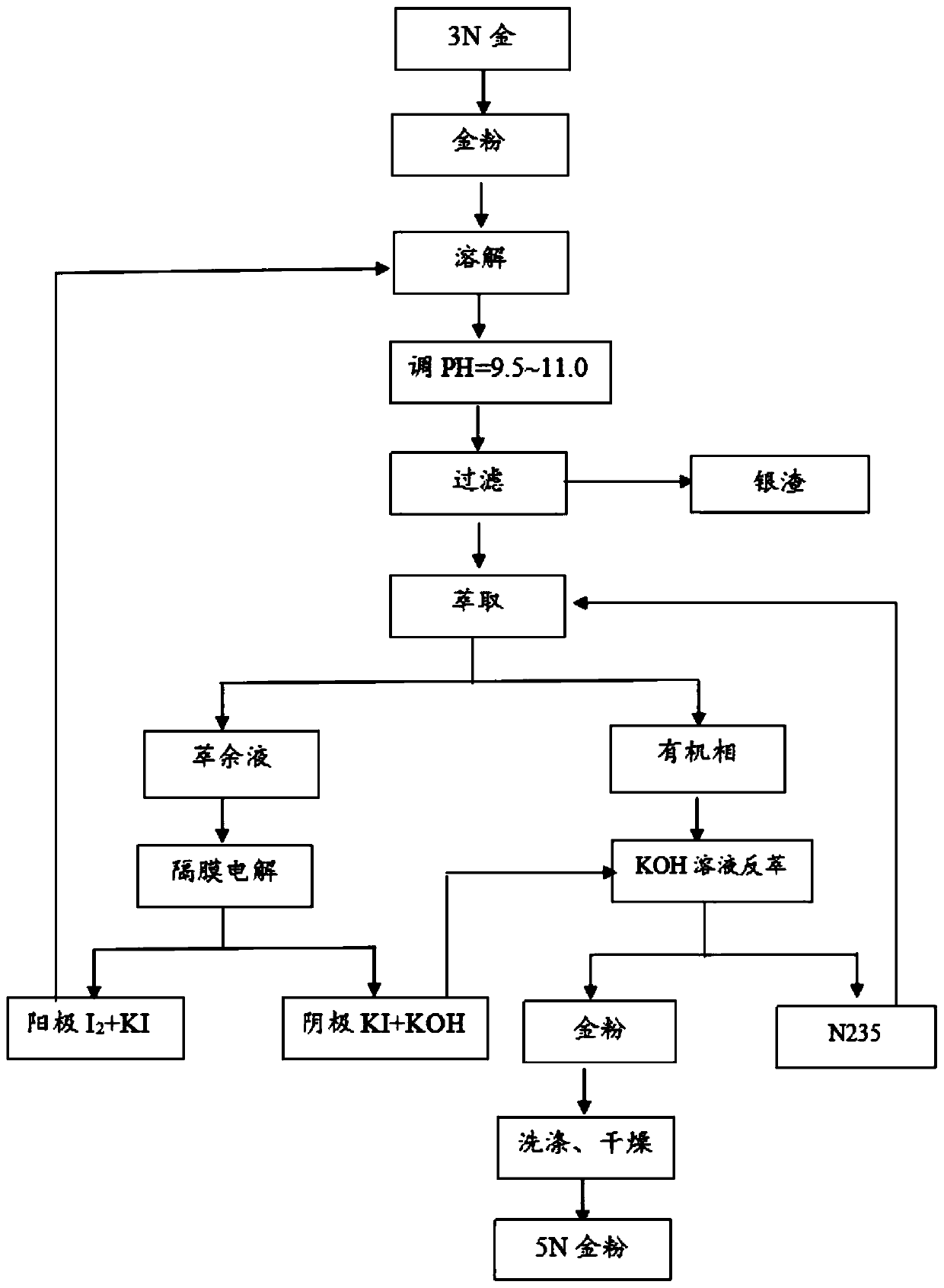

[0045] (1) Milling: take 3N gold as raw material to produce 60 mesh gold powder with milling equipment.

[0046] (2) Dissolving gold: put 10kg60 mesh gold powder into a plastic reaction kettle, add 95L ion-exchanged water, 35kg potassium iodide, 23kg iodine and 3kg potassium iodate, stir and dissolve at 40°C for 30min, the gold is completely dissolved, and obtain a gold-containing solution, potassium iodide iodide and The purity of potassium iodate was analytically pure.

[0047] (3) Adjust the pH value of the gold-containing solution to 9.5 with high-grade pure potassium hydroxide, filter through a precision filter, retain the filter residue to recover silver and copper, and send the filtrate to a centrifugal extractor for extraction.

[0048] (4) Extraction: extract gold with 30% N235+70% sulfonated kerosene, compared to O / A=1:1, the order is 3, the gold extraction rate is ≥99.92%, platinum and palladium are almost not extracted, and the organic phase is separated and sent t...

Embodiment 2

[0060] Other conditions are the same as in Example 1, except that the ratio of low-purity gold powder, ion-exchanged water, potassium iodide, iodine and potassium iodate is changed to 10kg: 95L: 40kg: 25kg: 5kg, and the dissolution temperature is changed to 50°C in step 2. The dissolution time was changed to 35min.

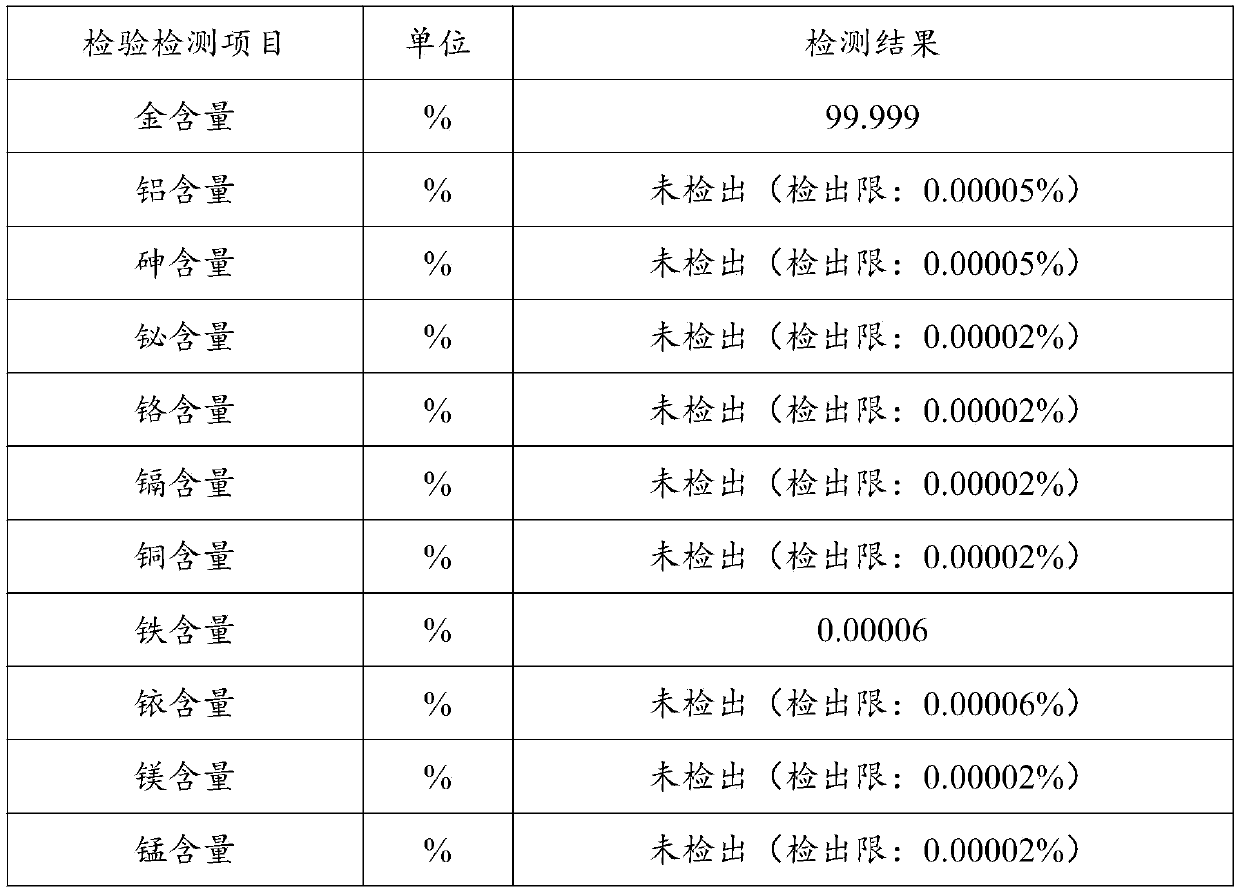

[0061] The purity of the obtained high-purity gold powder was tested, and the results showed that the purity of the high-purity gold powder could reach the 5N level, meeting the requirements of GB / T25933-2010.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com