Preparation technology of formaldehyde-free multi-layer solid-wood composite floor

A technology of solid wood composite flooring and preparation technology, which is applied in the field of flooring manufacturing, can solve the problems of high molecular activity, affecting normal use, and variability, and achieve the effects of long opening time of resin, easy production, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

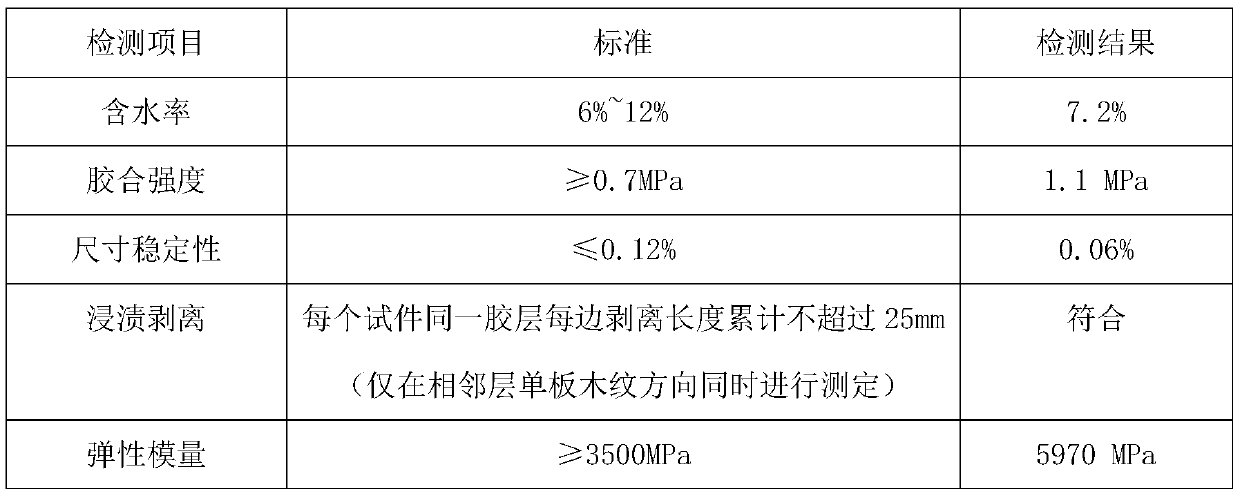

Embodiment 1

[0030] A preparation process for formaldehyde-free multi-layer solid wood composite flooring, comprising the following steps:

[0031] (1) Glue adjustment: mix the natural polymer resin adhesive: flour = 100:40 mass ratio for 15 minutes and mix evenly. The natural polymer resin adhesive used is self-made, and its ingredients are lignin, potassium hydroxide, melamine , carboxymethylcellulose, urea and water, the mass percent of each component is 35%, 4.5%, 3.7%, 1.2%, 2.8% and 52.8%;

[0032] (2) Glue sizing for substrate assembly: Arrange the wooden veneers with a thickness of 2.2mm and 1.7mm in a criss-cross pattern, and the amount of glue applied is 180g / m 2 ;

[0033] (3) Cold pressing and hot pressing: cold press the assembled slab first, and then hot press, wherein the cold pressing pressure is 1.0MPa, the time is 30min; the hot pressing pressure is 1.1MPa, the hot pressing efficiency is 70s / min, and the hot pressing Temperature 140°C;

[0034] (4) Substrate post-proce...

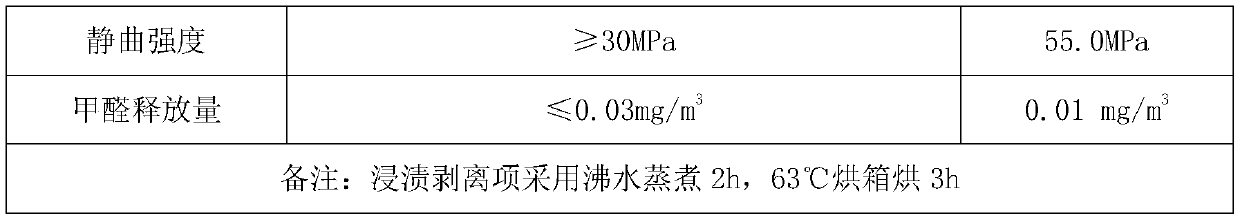

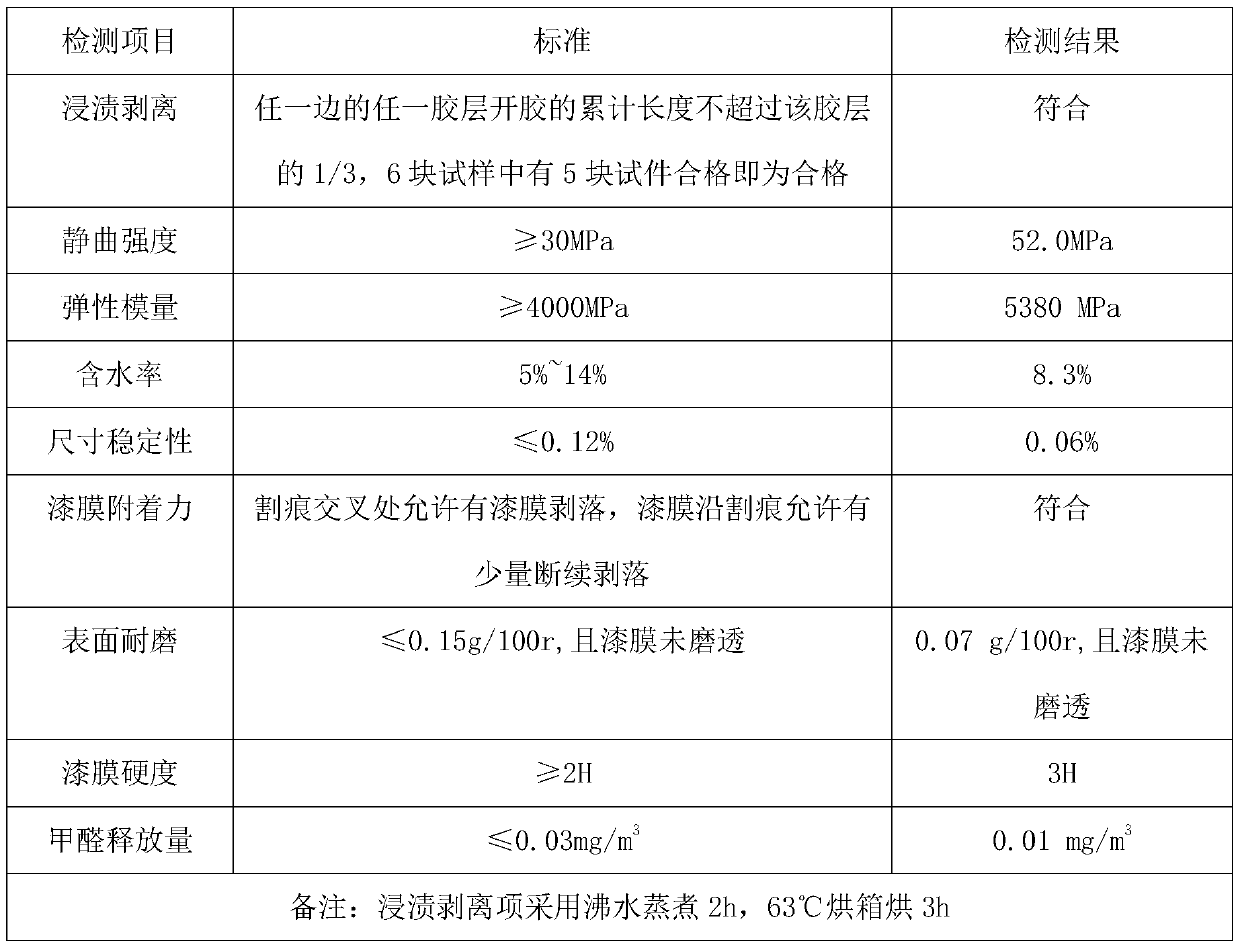

Embodiment 2

[0039] A method for manufacturing formaldehyde-free multi-layer solid wood composite flooring, specifically comprising the following steps:

[0040] (1) Glue adjustment: mix the natural polymer resin adhesive: flour = 100:40 mass ratio for 15 minutes and mix evenly. The natural polymer resin adhesive used is self-made, and its ingredients are lignin, potassium hydroxide, melamine , carboxymethyl cellulose, urea and water, the weight percentage of each component is 35%, 4.5%, 3.7%, 1.2%, 2.8% and 52.8%;

[0041] (2) Glue sizing for substrate assembly: Arrange the wooden veneers with a thickness of 2.2mm and 1.7mm in a criss-cross pattern, and the amount of glue applied is 180g / m 2 ;

[0042] (3) Cold pressing and hot pressing: cold press the assembled slab first, and then hot press, wherein the cold pressing pressure is 1.0MPa, the time is 30min; the hot pressing pressure is 1.1MPa, the hot pressing efficiency is 70s / min, and the hot pressing Temperature 140°C;

[0043] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com