Anti-freezing polyethylene power tube and preparation method thereof

A power pipe and polyethylene technology, which is applied to the field of antifreeze polyethylene power pipe and its preparation, can solve the problems of unsatisfactory impact strength, low toughness of high-density polyethylene, poor environmental stress cracking energy, etc., and achieve mechanical properties. Enhance, increase impact strength, meet the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

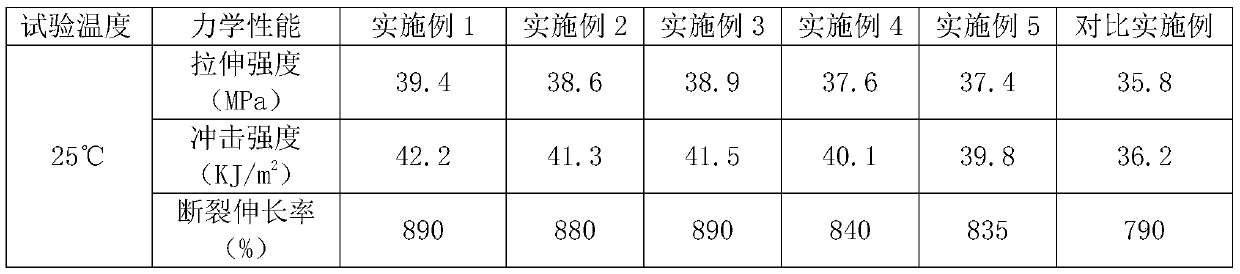

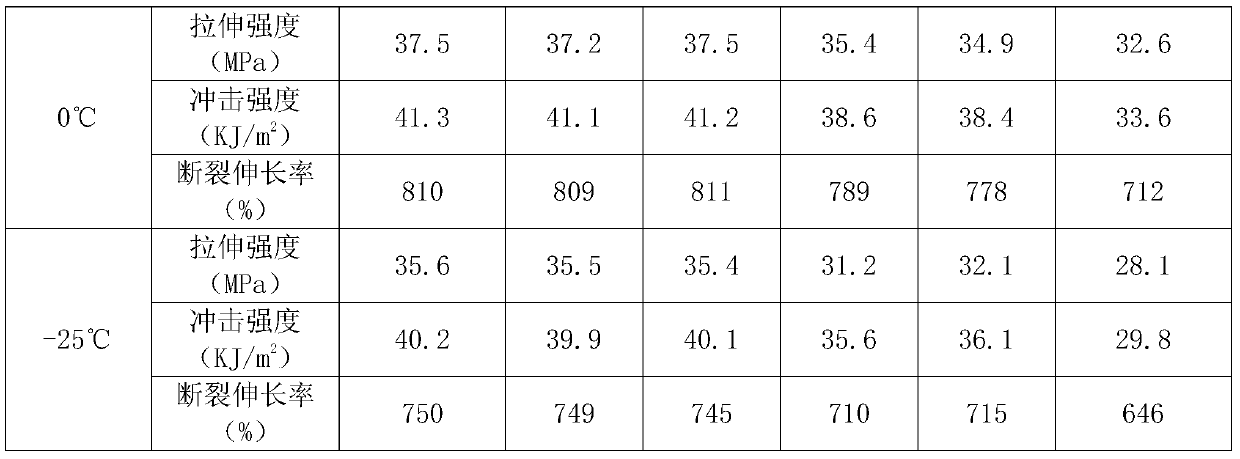

Examples

Embodiment 1

[0029] The preparation method of the antifreeze polyethylene power pipe of this embodiment includes the following steps:

[0030] 1. Weigh 10kg of carbon nanotubes and disperse them in a mixture of 98% concentrated sulfuric acid and 68% concentrated nitric acid with a volume ratio of 3:1. The mixed solution has a mass of 22.5kg. After mixing, use ultrasound. Vibrate, ultrasonic frequency 25000HZ, reaction time 2.5 hours, then filter and clean with deionized water to obtain carbon nanotubes with carboxyl groups after cutting;

[0031] 2. Take 100 parts of high-density polyethylene and heat it to 110°C. After the high-density polyethylene is completely melted, add the cut carbon nanotubes, stir well, and then add 15kg of potassium permanganate powder and stir. React for 35 minutes, add 0.4kg of trimethyltin after the reaction is complete, and stir evenly;

[0032] 3. The above reaction product is cooled and pelletized to obtain carbon nanotube modified high-density polyethylene.

[003...

Embodiment 2

[0037] The preparation method of the antifreeze polyethylene power pipe of this embodiment includes the following steps:

[0038] 1. Weigh 10kg of carbon nanotubes and disperse them in a mixture of 98% concentrated sulfuric acid and 68% concentrated nitric acid with a volume ratio of 3:1. The mixed solution has a mass of 20kg. After mixing, use ultrasound Oscillate, ultrasonic frequency 20000HZ, reaction time 2 hours, then filter and clean with deionized water to obtain carbon nanotubes with carboxyl groups after cutting;

[0039] 2. Take 100 parts of high-density polyethylene and heat it to 100°C. After the high-density polyethylene is completely melted, add the cut carbon nanotubes, stir well, and then add 10kg of potassium permanganate powder and stir. React for 30 minutes, add 0.2kg of trimethyltin after the reaction is complete, and stir evenly;

[0040] 3. The above reaction product is cooled and pelletized to obtain carbon nanotube modified high-density polyethylene.

[0041] ...

Embodiment 3

[0045] The preparation method of the antifreeze polyethylene power pipe of this embodiment includes the following steps:

[0046] 1. Weigh 10kg of carbon nanotubes and disperse them in a mixture of 98% concentrated sulfuric acid and 68% concentrated nitric acid with a volume ratio of 3:1. The mixed solution has a mass of 25kg. After mixing, use ultrasonic Oscillate, ultrasonic frequency 30000HZ, reaction time 3 hours, then filter and clean with deionized water to obtain carbon nanotubes with carboxyl groups after cutting;

[0047] 2. Take 100 parts of high-density polyethylene and heat it to 120°C. After the high-density polyethylene is completely melted, add the cut carbon nanotubes, stir well, and then add 20kg of potassium permanganate powder and stir. React for 40 minutes, add 0.4kg of trimethyltin after the reaction is complete, and stir evenly;

[0048] 3. The above reaction product is cooled and pelletized to obtain carbon nanotube modified high-density polyethylene.

[0049] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com