Genetically engineered saccharomycetes for producing baicalein compounds as well as construction method and application of genetically engineered saccharomycetes

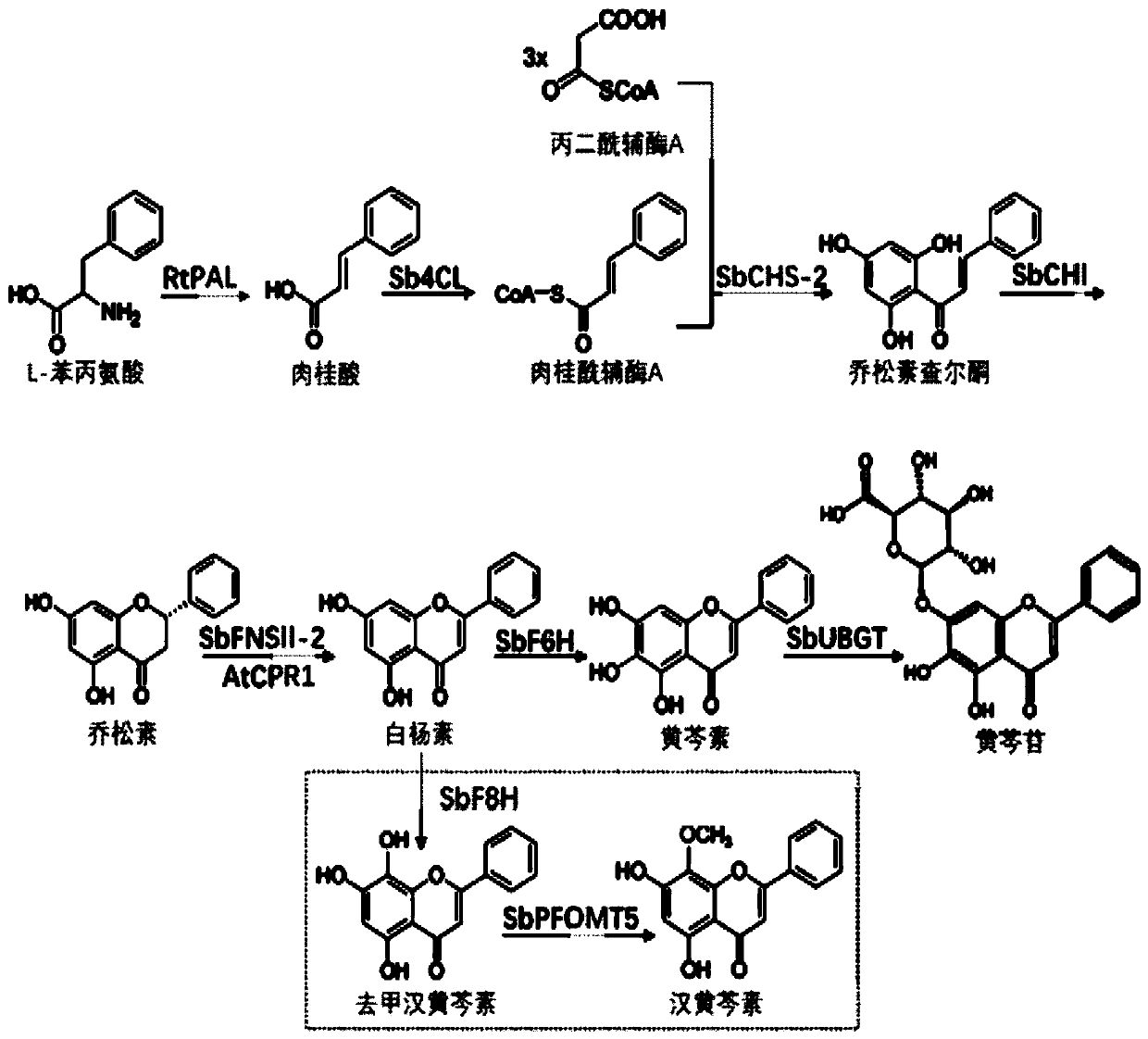

A technology for baicalein and compounds, which is applied in the production of baicalein compounds and the field of genetically engineered yeast, can solve the problems of high requirements, consumption of carbon source and energy of host cells, adverse effects and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0114] Embodiment 1, the construction of expression plasmid

[0115] 1.P GAP Construction of plasmids expressing each gene

[0116] The genes RtPAL, AtCPR1 and SbUBGT were fully synthesized by Suzhou Jinweizhi Biotechnology Co., Ltd. and directly constructed on the vector plasmid pGAP Zα (Invitrogen). Plasmid names: pGAP_RtPal, pGAP_AtCPR1pGAP_SbUBGT. The original plasmids of other genes (Sb4CL, SbCHS-2, SbCHI, SbFNSII-2, SbF6H, SbF8H, SbPFOMT5) were all from Shanghai Chenshan Plant Science Research Center, Chinese Academy of Sciences. Design specific primers, use the original plasmid of each gene as a template, and use the corresponding primers in Table 1 to amplify related genes derived from Scutellaria baicalensis (Sb4CL, SbCHS-2, SbCHI, SbFNSII-2, SbF6H, SbF8H, SbPFOMT5) by PCR ; Use AsuII and KpnI to double-digest plasmid pGAP Zα, and use the seamless assembly kit to integrate each gene into plasmid pGAP Zα respectively. P GAP Downstream, after the sequence is correct,...

Embodiment 2

[0139] Embodiment 2, preparation of target recombinant yeast

[0140]1. PCR verification of recombinant strains

[0141] Each DNA fragment and the corresponding gRNA plasmid were electrotransformed into Pichia pastoris GS115-Δku70 (refer to 201910403132.1). After recovery, they were spread on YND solid medium, and after 5 days of cultivation, fresh colonies were picked and cultivated in YPD liquid medium. The yeast genome extraction kit extracts the genome of each transformant, and identifies the integration of each gene synthesized by baicalein into the Pichia pastoris genome by cloning PCR reaction.

[0142] Cloning PCR reaction conditions:

[0143] (1) Initial denaturation at 95°C for 5 minutes;

[0144] (2) Denaturation at 95°C for 30s, annealing at 50°C for 30s, extension at 72°C for 1min / kb, and 30 cycles of reaction;

[0145] (3) Finally extend at 72°C for 7min.

[0146] 2. Acquisition of recombinant bacteria containing 7 foreign genes

[0147] Design specific prim...

Embodiment 3

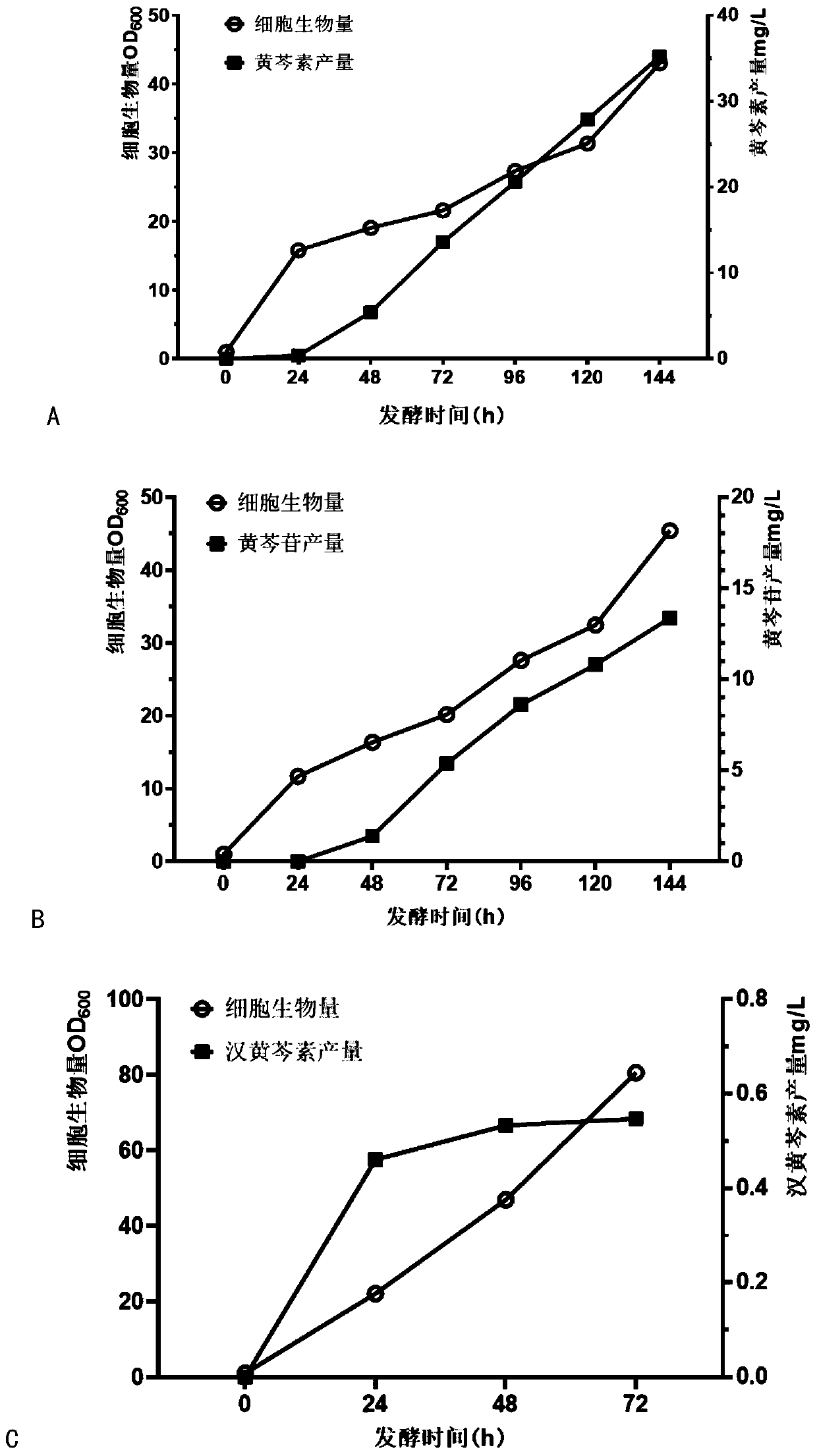

[0154] Embodiment 3, 250ml Erlenmeyer flask fermentation process of recombinant engineering bacteria

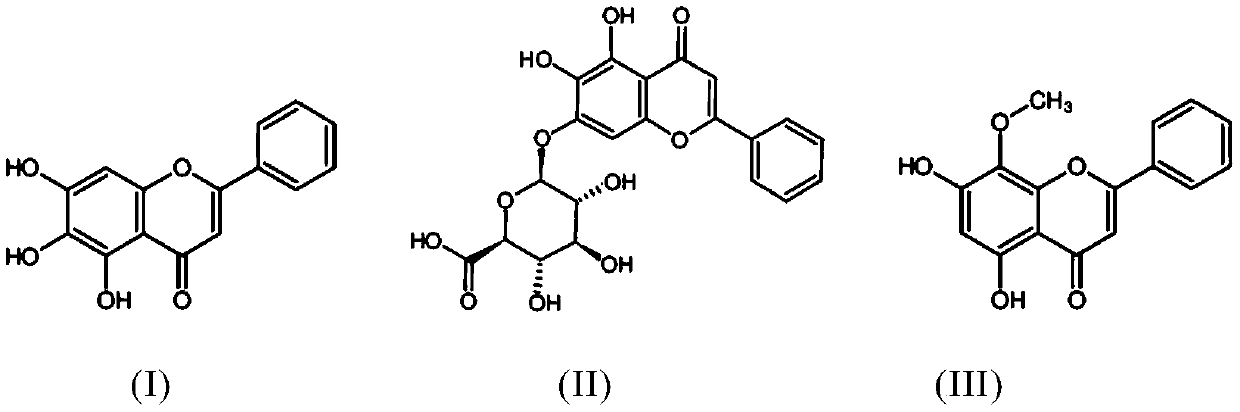

[0155] Baicalein-producing strain: it contains 7 exogenous genes: RtPAL, Sb4CL, SbCHS-2, SbCHI, SbFNSII-2, SbF6H, AtCPR1.

[0156] The strain producing baicalin: it contains 8 foreign genes: RtPAL, Sb4CL, SbCHS-2, SbCHI, SbFNSII-2, SbF6H, AtCPR1, SbUBGT.

[0157] The strain producing wogonin: it contains 2 foreign genes: SbF8H and SbPFOMT5.

[0158] Cultivate the recombinant bacteria to the logarithmic phase in the liquid YPD medium at 30°C with a rotational speed of 200r / min, collect the bacteria and wash them twice with sterile water, then transfer to a 250mL Erlenmeyer flask containing 50mL of YPD liquid medium (the strains that produce baicalein or baicalin do not need to add additional precursors, and the strains that produce wogonin also add 200 μM chrysin), and cultivate them at 30°C with a rotation speed of 200r / min (the strains that produce baicalein or baicalin are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com