Functional material, positive plate containing functional material and lithium ion battery

A technology of lithium-ion batteries and functional materials, which is applied in the field of positive electrodes and lithium-ion batteries, can solve problems such as limited effects, and achieve the effects of improving safety performance, avoiding thermal runaway, and improving impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of the present invention will be further described in detail in conjunction with specific examples below. It should be understood that the following examples are only for illustrating and explaining the present invention, and should not be construed as limiting the protection scope of the present invention. All technologies realized based on the above contents of the present invention are covered within the scope of protection intended by the present invention.

[0062] The experimental methods used in the following examples are conventional methods unless otherwise specified; the reagents and materials used in the following examples can be obtained from commercial sources unless otherwise specified.

Embodiment 1

[0064] (1) Preparation of functional materials in positive electrode slurry

[0065] 0.5 g of polystyrene and 2 g of lithium metal powder were stirred and heated to the melting temperature of polystyrene under an argon atmosphere, and then mixed uniformly to obtain a functional material in which a polymer material was coated with a reducing material.

[0066] In the prepared functional material, the shell is polystyrene, and the core is lithium metal powder; the mass ratio of the shell to the core is 1:4, the thickness of the shell is 0.5 μm, and the average particle size of the functional material is about 5 μm.

[0067] (2) Preparation of positive pole piece

[0068] a. In terms of mass fraction, mix 33.3wt% NMP, 49.3wt% lithium iron phosphate, 6.7wt% polytetrafluoroethylene, 5wt% SP, 5wt% Ketjen black, and 0.7wt% of the above functional materials, stir and disperse evenly to obtain Positive electrode slurry;

[0069] b. coating the positive electrode slurry on the positi...

Embodiment 2-6 and comparative example 1

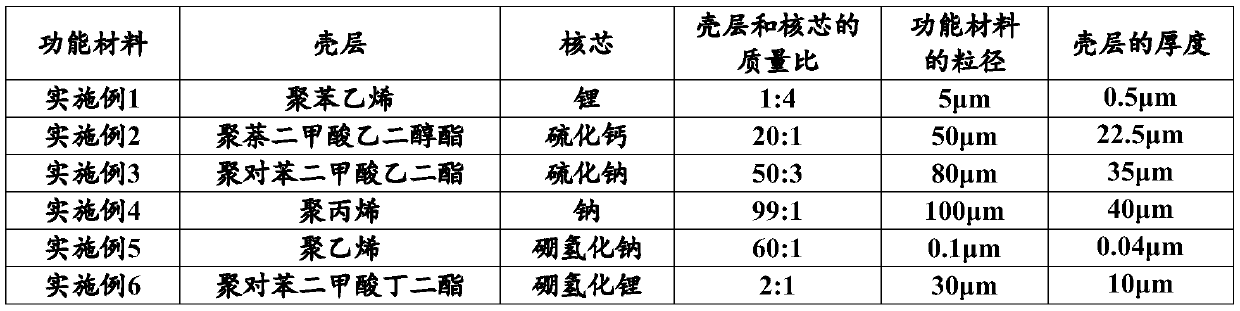

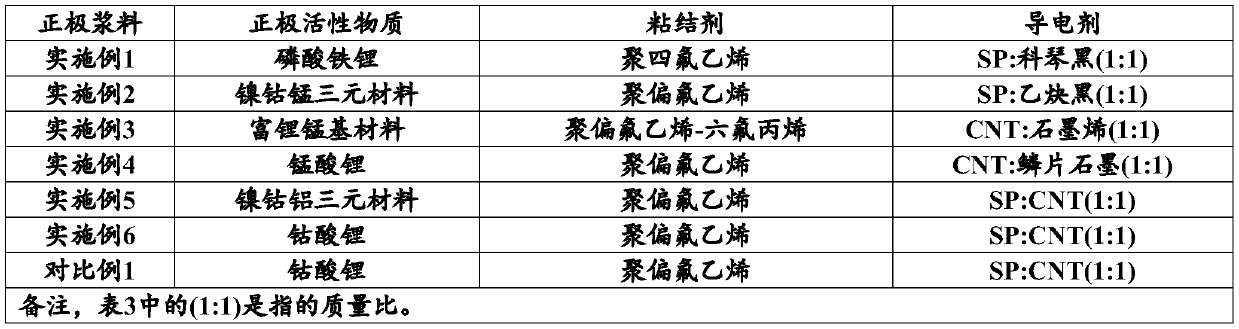

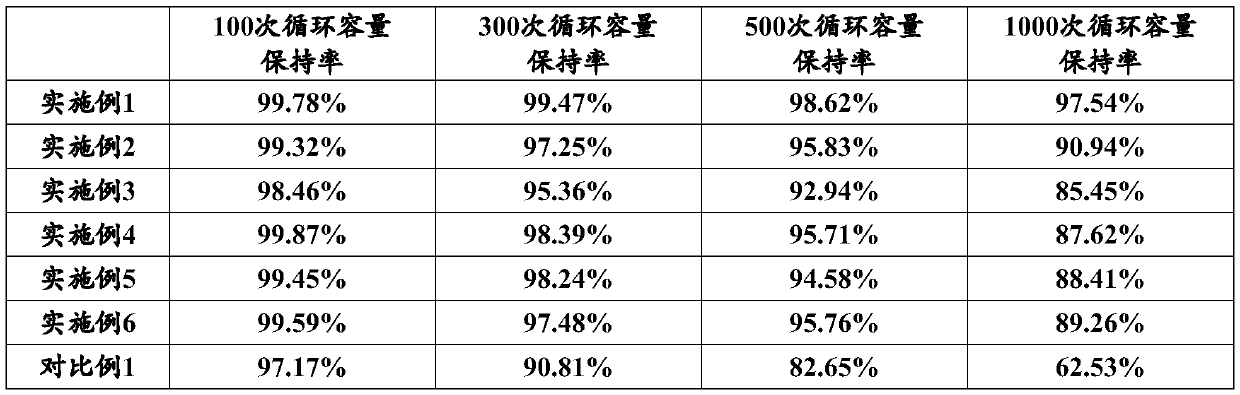

[0078] The preparation process of Examples 2-6 and Comparative Example 1 is the same as that of Example 1, the only difference is that the selection of functional materials is different, and the selection and mass fraction of each component in the positive electrode slurry are different, as shown in Table 1-Table 3 below:

[0079] The parameters of the functional material in the positive electrode slurry prepared in Table 1 Example 1-6

[0080]

[0081] The mass fraction of each component of the positive electrode slurry of table 2 embodiment 1-6 and comparative example 1

[0082] Positive electrode slurry Solvent wt% Positive electrode active material wt% Binder wt% Conductive agent wt% Functional material wt% Example 1 33.33 49.33 6.67 10 0.67 Example 2 75 24.4975 0.125 0.375 0.0025 Example 3 66.67 27.33 2.33 3.34 0.33 Example 4 64.29 33.93 0.61 0.89 0.28 Example 5 54.55 38.64 1.82 4.77 0.22 Example ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com