Aqueous single component conductive coating for insulator and preparation method thereof

A single-component technology for insulators, applied in conductive coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve problems such as poor corrosion protection, insufficient airtightness of insulators, and inconvenient construction, etc., to achieve excellent long-term sealing , Fast establishment of hardness and high protection life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

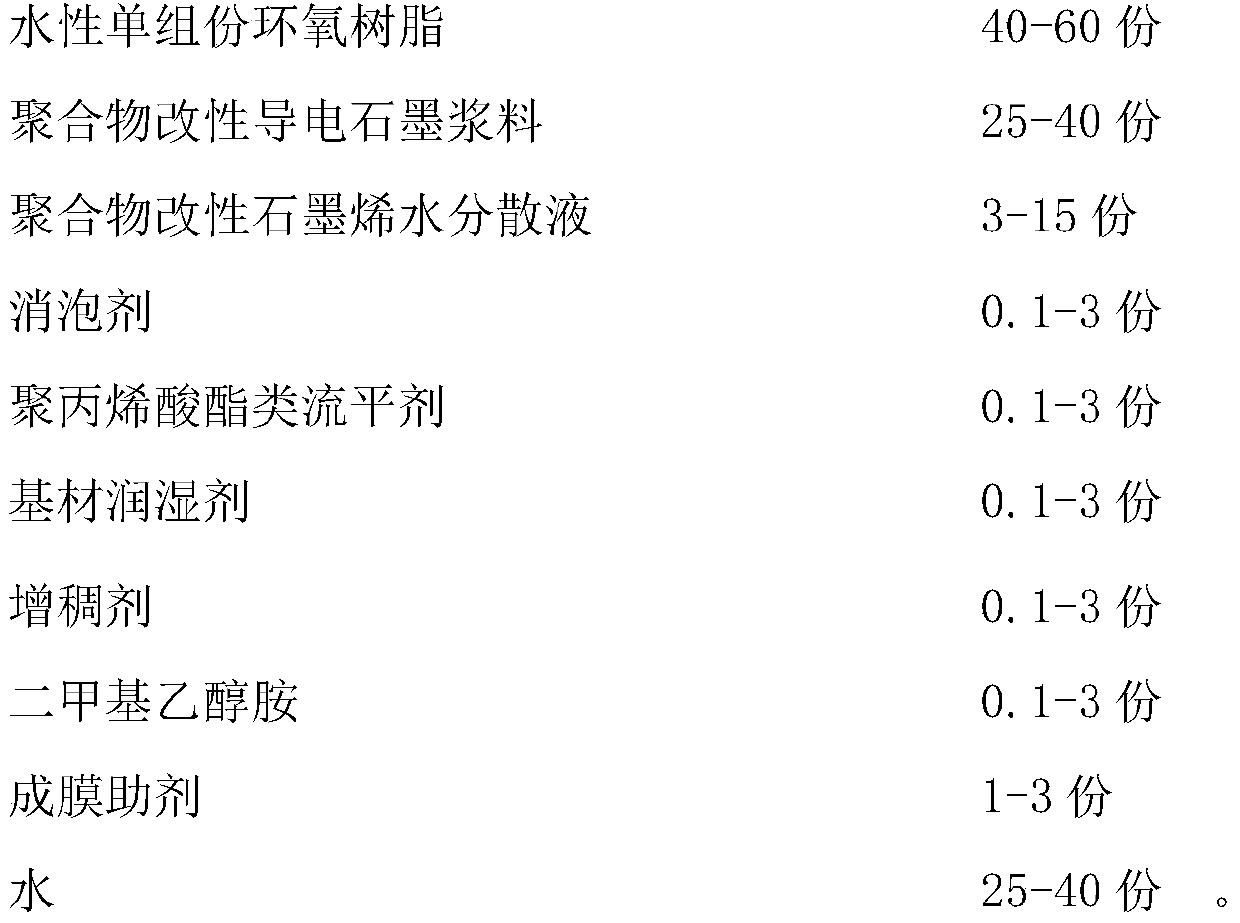

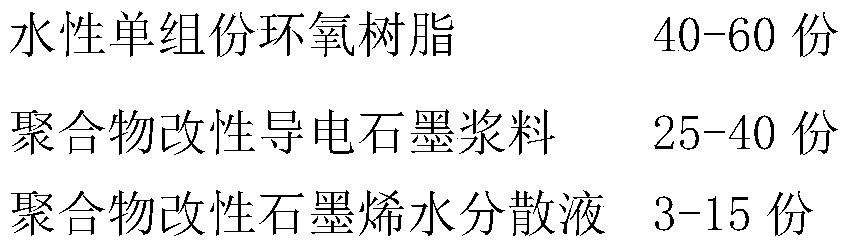

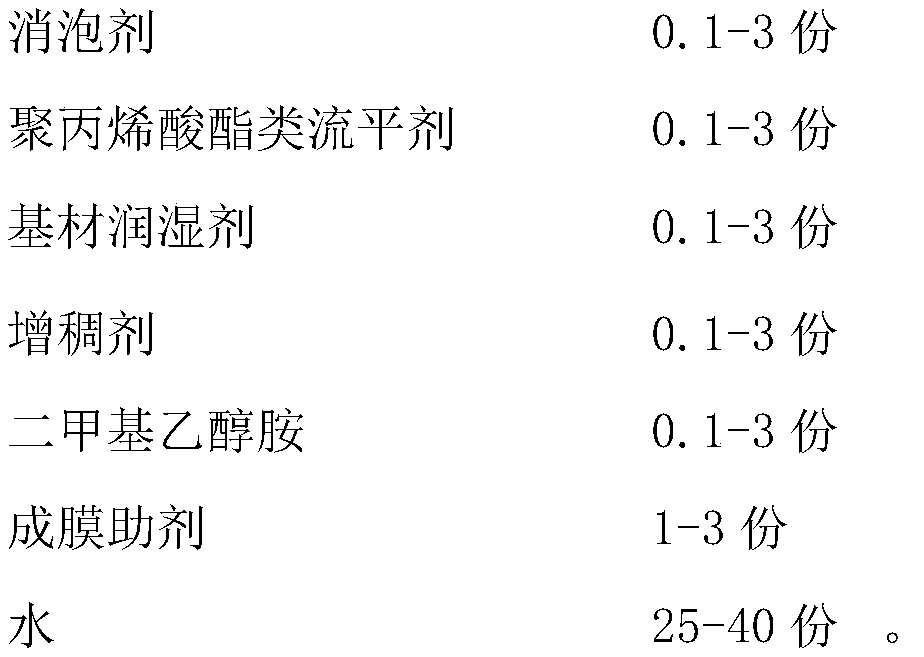

[0031] (1) Preparation of polymer-modified graphene aqueous dispersion: add water and sodium hydroxide to a container and stir evenly. After adding graphite oxide, aniline and pyrrole and mixing, ultrasonically disperse uniformly for 30 minutes, then transfer to ice-water bath for 10 minutes. Within 1h, an aqueous solution of ammonium persulfate was slowly added to the above mixed solution. Under the condition of ice-water bath, continue to stir and react for 15-25h, add a small amount of ammonia water, adjust the pH value of the system to 10-11, add hydrazine hydrate solution, and carry out reflux reaction at 82-88°C for 18-22h. After the reflux reaction is completed, sequentially Wash the product with absolute ethanol and distilled water until it is transparent and the pH value is 7.5 to 8.5 to obtain a solid primary product; after mixing the above solid with a wetting agent and water evenly, add 0.01mol / L sulfuric acid dropwise to adjust the pH value 6.5-7.5, ultra-dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com