Preparation method and application method of carboxylated magnetic polymer microspheres

An application method, carboxylation technology, applied in the field of adsorption materials, can solve the problems of non-reusable, low adsorption efficiency of adsorption materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

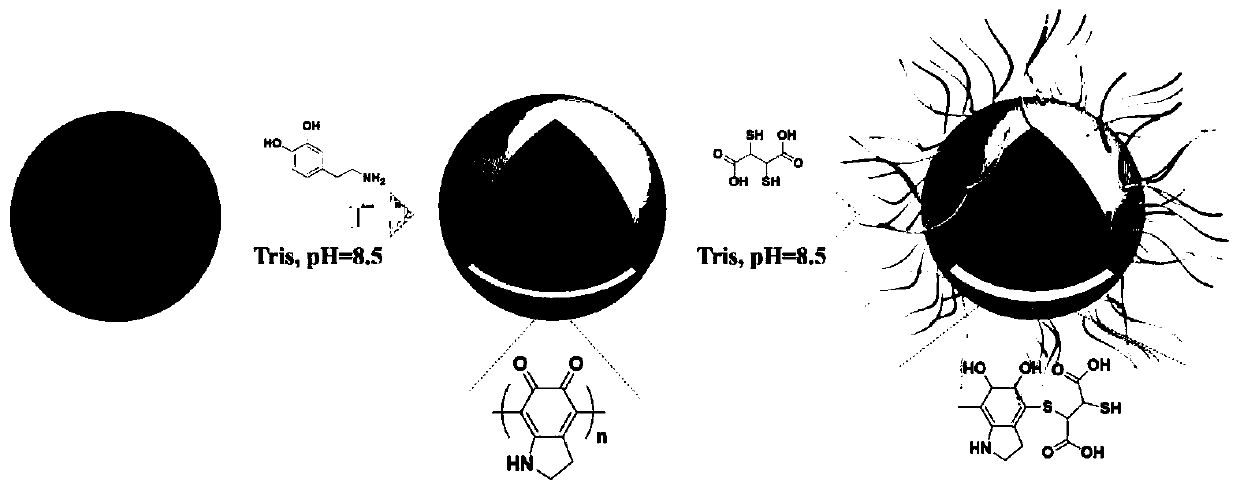

[0032] Such as Figure 1 to Figure 5 Shown, a kind of preparation method of carboxylated magnetic polymer microspheres, described method comprises the steps:

[0033] Carboxylating the pretreated magnetic nanoparticles with 2,3-dimercaptosuccinic acid to obtain magnetic composite particles;

[0034] Dispersing the magnetic composite particles in an alkaline buffer, and reacting with 2,3-dimercaptosuccinic acid at room temperature under stirring;

[0035] The product obtained by the stirring reaction is separated under the action of a magnetic field to obtain a solid product;

[0036] The solid product is treated to remove impurities and dried to obtain carboxylated magnetic polymer microspheres.

[0037] In this embodiment, the method for pretreating the magnetic nanoparticles includes encapsulating the magnetic nanoparticles with polydopamine.

[0038] In this embodiment, the mass ratio of the magnetic nanoparticles to the 2,3-dimercaptosuccinic acid when the magnetic comp...

Embodiment 1

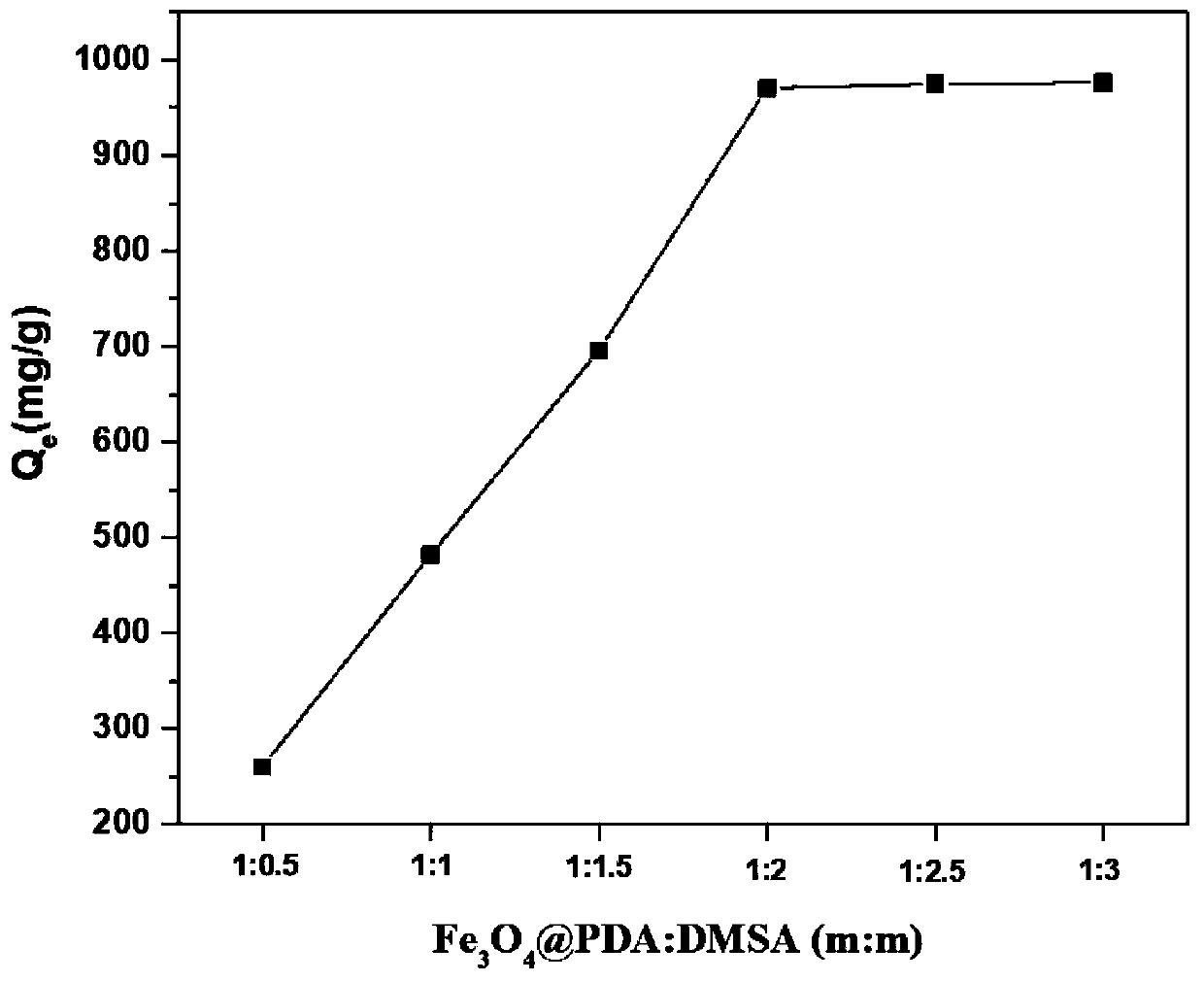

[0053] respectively by Fe 3 o 4 The mass ratio of @PDA to 2,3-dimercaptosuccinic acid (DMSA) is 1:0.5, 1:1, 1:1.5, 1:2, 1:2.5, 1:3 for functionalization, Fe 3 o 4 @PDA was ultrasonically dispersed in 50 mL of Tris buffer solution with pH=8.5, and then a certain amount of DMSA was added, and then stirred at room temperature for 8 h. After the reaction, the solid product was separated by an external magnetic field, washed repeatedly with water and ethanol to remove impurities, and dried to obtain carboxylated magnetic polymer microspheres (Fe 3 o 4 @PDA-COOH).

[0054] Fe will be produced 3 o 4 Add @PDA-COOH to 100mg / L methylene blue solution with pH=7, after 30min of adsorption, the adsorption effect is as follows figure 2 shown. from figure 2 It can be seen that with the increase of mass ratio, Fe 3 o 4 The adsorption capacity of @PDA-COOH magnetic polymer microspheres is also improving, and when the mass ratio reaches 1:2, the adsorption capacity reaches the high...

Embodiment 2

[0056] Take 0.04g Fe3 o 4 @PDA was ultrasonically dispersed in 50 mL of Tris buffer solution with pH=8.5, then 0.08 g of DMSA was added, and then stirred at room temperature for 8 h. After the reaction, the solid product was separated by an external magnetic field, washed repeatedly with water and ethanol to remove impurities, and dried to obtain carboxylated magnetic polymer microspheres (Fe 3 o 4 @PDA-COOH).

[0057] Take the same mass of Fe 3 o 4 @PDA-COOH was added to 100mg / L methylene blue solution of pH=2, pH=3, pH=4, pH=5, pH=6, pH=7, pH=8, pH=9 respectively, after adsorption for 30min , the adsorption effect is obtained as Figure 4 shown. from Figure 4 It can be seen that with the increase of solution pH, Fe 3 o 4 The zeta potential of @PDA-COOH decreased continuously, and the adsorption amount gradually increased accordingly. Since cationic dyes are unstable under alkaline conditions, the optimum adsorption pH=7 obtained in the experiment;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com