Mn-C catalytic material based on MOFs as well as preparation method and application thereof

A catalytic material, mn-c technology, applied in the field of catalysis, can solve the problems of reduced electron density and reduced catalytic ability of graphite layer, and achieve the effects of remarkable ozone removal performance, low cost and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of the Mn-C catalytic material based on MOFs, concrete steps are as follows:

[0026] (1) Preparation of Mn-MOFs: 3.0mmol0.5937gMnCl 2 4H 2 O was dissolved in 5 mL distilled water, 1.0 mmol H 3 BTC was dissolved in 5.0 mL of DMF, and the two solutions were mixed slowly. Move the mixed solution to a polytetrafluoroethylene-lined reaction kettle, heat up to 120°C at a rate of 5°C / min, keep at 120°C for 96 hours, cool to room temperature, and wash with absolute ethanol and deionized water at 4000r / min. The crystals were washed several times (firstly with absolute ethanol for 3 times, then with deionized water for 3 times), and then freeze-dried to obtain white powder Mn-MOFs.

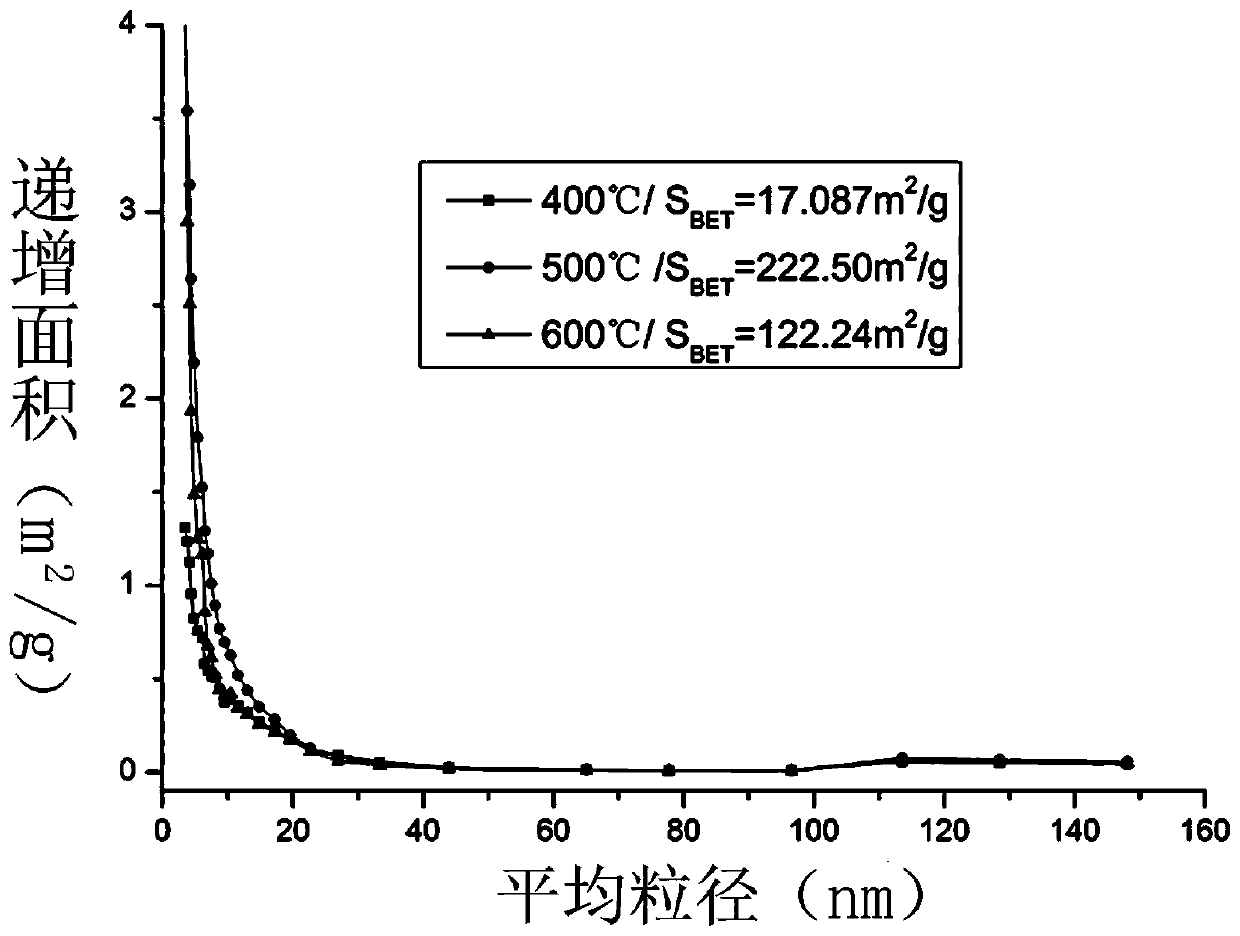

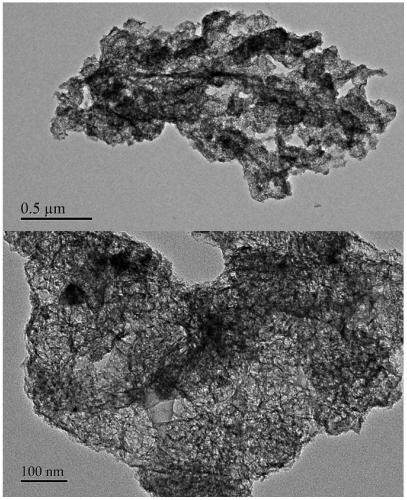

[0027] (2) Preparation of Mn-C catalytic material: heating the Mn-MOFs described in (1) in a tube furnace with temperature control. Weigh an appropriate amount of Mn-MOFs and place it in a quartz boat. Under a nitrogen atmosphere, heat up to 500°C at a rate of 5°C / mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com