Aerogel-containing thermal insulation material and preparation method thereof

A thermal insulation material and airgel technology, applied in the field of thermal insulation materials, can solve the problems of high cost, difficulty in batch production of organic flexible airgel, unsuitable for civilian market, etc., and achieve low density and low production cost , the effect of excellent cold resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

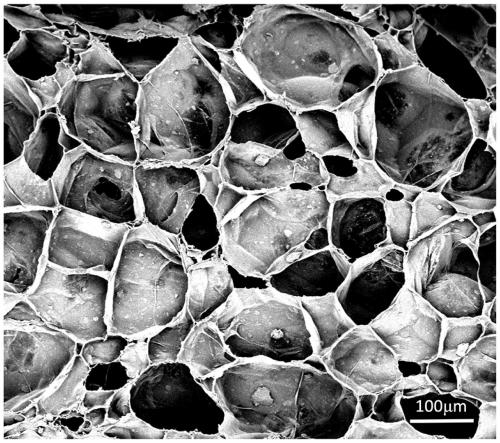

Image

Examples

Embodiment 1

[0066] The formula of raw materials by mass parts is as follows:

[0067] NBR (acrylonitrile content 25%, 50 parts) / PVC (polymerization degree 1000, 50 parts), NBR and PVC total 100 parts, plasticizer TOTM 14 parts, calcium / zinc heat stabilizer takes 2.5 parts of PVC consumption, 5 parts of zinc oxide, 1.5 parts of stearic acid, 15 parts of foaming agent AC, 1.5 parts of sulfur, 1 part of accelerator TMTD (TT), 1.2 parts of accelerator CZ, 3 parts of anti-aging agent, 8 parts of graphene airgel , 8 parts of phase change microcapsules, 20 parts of light calcium carbonate (average particle diameter 70nm), 10 parts of white carbon black, 2 parts of deodorant.

[0068] The preparation process of airgel-containing thermal insulation material is as follows:

[0069] Step 1, PVC pre-swelling

[0070] Heat PVC to 60°C, add plasticizer triisooctyl trimellitate (TOTM) and calcium / zinc heat stabilizer, and mix the raw materials thoroughly in a mechanical mixer at a speed of 400r / min fo...

Embodiment 2

[0084] The formula of raw materials by mass parts is as follows:

[0085] NBR (acrylonitrile content 25%, 50 parts) / PVC (polymerization degree 1000, 50 parts), NBR and PVC total 100 parts, plasticizer TOTM 14 parts, calcium / zinc heat stabilizer takes 2.5 parts of PVC consumption, 5 parts of zinc oxide, 1.5 parts of stearic acid, 13 parts of foaming agent AC, 1.5 parts of sulfur, 1 part of accelerator TMTD (TT), 1.2 parts of accelerator CZ, 3 parts of anti-aging agent, 10 parts of graphene airgel , 8 parts of phase change microcapsules, 20 parts of light calcium carbonate (average particle diameter 70nm), 10 parts of white carbon black, 2 parts of deodorant.

[0086] The preparation process of airgel-containing thermal insulation material is as follows:

[0087] Step 1, PVC pre-swelling

[0088] Heat PVC to 60°C, add plasticizer triisooctyl trimellitate (TOTM) and calcium / zinc heat stabilizer, and mix the raw materials thoroughly in a mechanical mixer at a speed of 400r / min f...

Embodiment 3

[0102] The formula of raw materials by mass parts is as follows:

[0103] NBR (acrylonitrile content 25%, 60 parts) / PVC (polymerization degree 1000, 40 parts), NBR and PVC total 100 parts, plasticizer TOTM 14 parts, calcium / zinc heat stabilizer takes 2.5 parts of PVC consumption, 5 parts of zinc oxide, 1.5 parts of stearic acid, 15 parts of foaming agent AC, 1.5 parts of sulfur, 1 part of accelerator TMTD (TT), 1.2 parts of accelerator CZ, 3 parts of anti-aging agent, 8 parts of graphene airgel , 8 parts of phase change microcapsules, 20 parts of light calcium carbonate (average particle diameter 70nm), 13 parts of white carbon black, 2 parts of deodorant.

[0104] The preparation process of airgel-containing thermal insulation material is as follows:

[0105] Step 1, PVC pre-swelling

[0106] Heat PVC to 60°C, add plasticizer triisooctyl trimellitate (TOTM) and calcium / zinc heat stabilizer, and mix the raw materials thoroughly in a mechanical mixer at a speed of 400r / min fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com