Anti-aging modified asphalt and preparation method thereof

A modified asphalt, anti-aging technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of reduced service life of asphalt pavement, hardening of asphalt pavement, unsatisfactory effect, etc., to achieve excellent anti-aging performance, improve Effect of penetration resistance and corrosion resistance, excellent ultraviolet shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

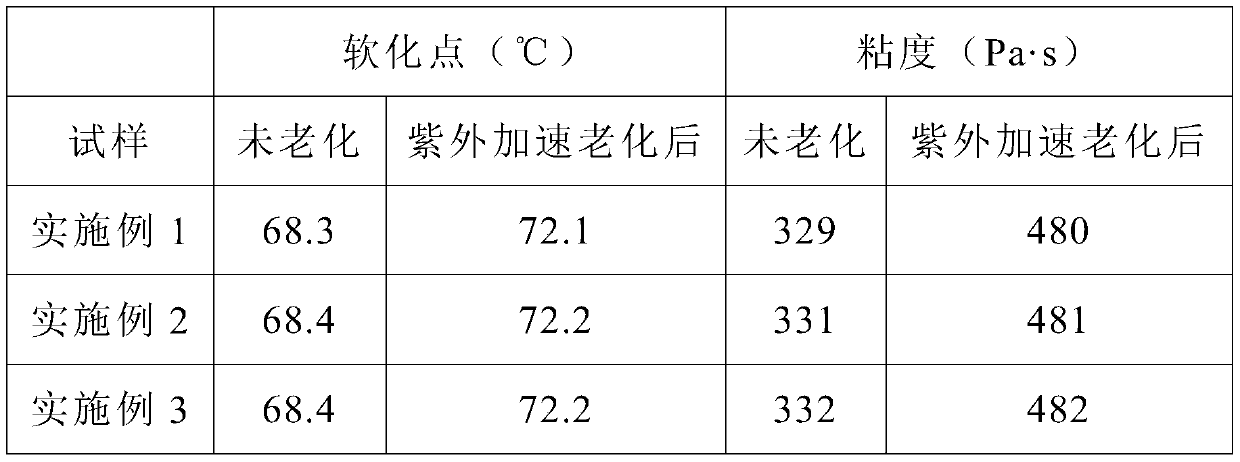

Examples

Embodiment 1

[0044] S1: Prepare materials;

[0045] S2: Preparation of modified SBS rubber:

[0046] Take layered manganese dioxide and nitric acid, stir and react for 3 days, filter with suction, wash with water until the pH is 6, and dry at 80°C for 7 hours to obtain material A; take tetramethylammonium hydroxide, dissolve in deionized water, stir for 10 minutes, and then add the material A, stirred for 7 days, centrifuged and washed to obtain material B;

[0047] Take material B and dioctadecyldimethylammonium chloride, stir at 50°C for 3 hours, centrifuge, wash with water, and dry in vacuum at 50°C to obtain a modified material;

[0048] Take SBS rubber, heat stabilizer, modified material and plasticizer, place it in a mixer and knead for 10 minutes at a mixing temperature of 160°C to obtain modified SBS rubber;

[0049] S3: Preparation of additives:

[0050] Take cerium nitrate hexahydrate and zinc nitrate hexahydrate, mix and stir for 5 minutes, then add graphene oxide and citric ...

Embodiment 2

[0059] S1: Prepare materials;

[0060] S2: Preparation of modified SBS rubber:

[0061] Take layered manganese dioxide and nitric acid, stir and react for 3.5 days, filter with water, wash with water until the pH is 6, and dry at 80°C for 7.5 hours to obtain material A; take tetramethylammonium hydroxide, dissolve in deionized water, stir for 15 minutes, and then Add material A, stir for 7 days, centrifuge and wash to obtain material B;

[0062] Take material B and dioctadecyldimethylammonium chloride, stir at 52°C for 3.2h, centrifuge, wash with water, and dry in vacuum at 50°C to obtain the modified material;

[0063] Take SBS rubber, heat stabilizer, modified material and plasticizer, put it in a mixer and knead for 14min, and the kneading temperature is 163°C to obtain modified SBS rubber;

[0064] S3: Preparation of additives:

[0065] Take cerium nitrate hexahydrate and zinc nitrate hexahydrate, mix and stir for 8 minutes, then add graphene oxide and citric acid, heat...

Embodiment 3

[0074] S1: Prepare materials;

[0075] S2: Preparation of modified SBS rubber:

[0076] Take layered manganese dioxide and nitric acid, stir and react for 3.5 days, filter with water, wash with water until the pH is 6, and dry at 80°C for 8 hours to obtain material A; take tetramethylammonium hydroxide, dissolve in deionized water, stir for 20 minutes, and then add Material A was stirred for 7 days, centrifuged and washed to obtain material B;

[0077] Take material B and dioctadecyldimethylammonium chloride, stir at 55°C for 3.5h, centrifuge, wash with water, and dry in vacuum at 50°C to obtain the modified material;

[0078] Take SBS rubber, heat stabilizer, modified material and plasticizer, place it in a mixer and knead for 15 minutes, and the kneading temperature is 165°C to obtain modified SBS rubber;

[0079] S3: Preparation of additives:

[0080] Take cerium nitrate hexahydrate and zinc nitrate hexahydrate, mix and stir for 10 minutes, then add graphene oxide and ci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com