Preparation method of iso-paraffin composition

A technology of isoparaffin and composition, which is applied in the field of preparation of isoparaffin composition, can solve problems such as low carbon number of naphtha, influence on quality of isoparaffin composition, quality of solvent oil, etc., and achieve good biodegradability , Facilitate adsorption and separation, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The first Fischer-Tropsch crude liquid wax, the second Fischer-Tropsch crude liquid wax, the third Fischer-Tropsch crude liquid wax and the fourth Fischer-Tropsch synthesis process of the 1.2 million tons / year coal-to-chemicals project of Inner Mongolia Yitai Chemical Co., Ltd. For the crude liquid wax, the raw materials are first mixed, and the raw materials do not contain naphthenes.

[0046] a) mixing the first Fischer-Tropsch crude liquid wax, the second Fischer-Tropsch crude liquid wax, the third Fischer-Tropsch crude liquid wax and the fourth Fischer-Tropsch crude liquid wax, the first Fischer-Tropsch crude liquid wax, the second Fischer-Tropsch crude liquid wax The Tropsch crude liquid wax, the third Fischer-Tropsch crude liquid wax and the fourth Fischer-Tropsch crude liquid wax do not contain naphthenes;

[0047] b) After the mixed material obtained in step a) enters the feed buffer tank, after being boosted by the machine pump and exchanging heat with the hot ...

Embodiment 2

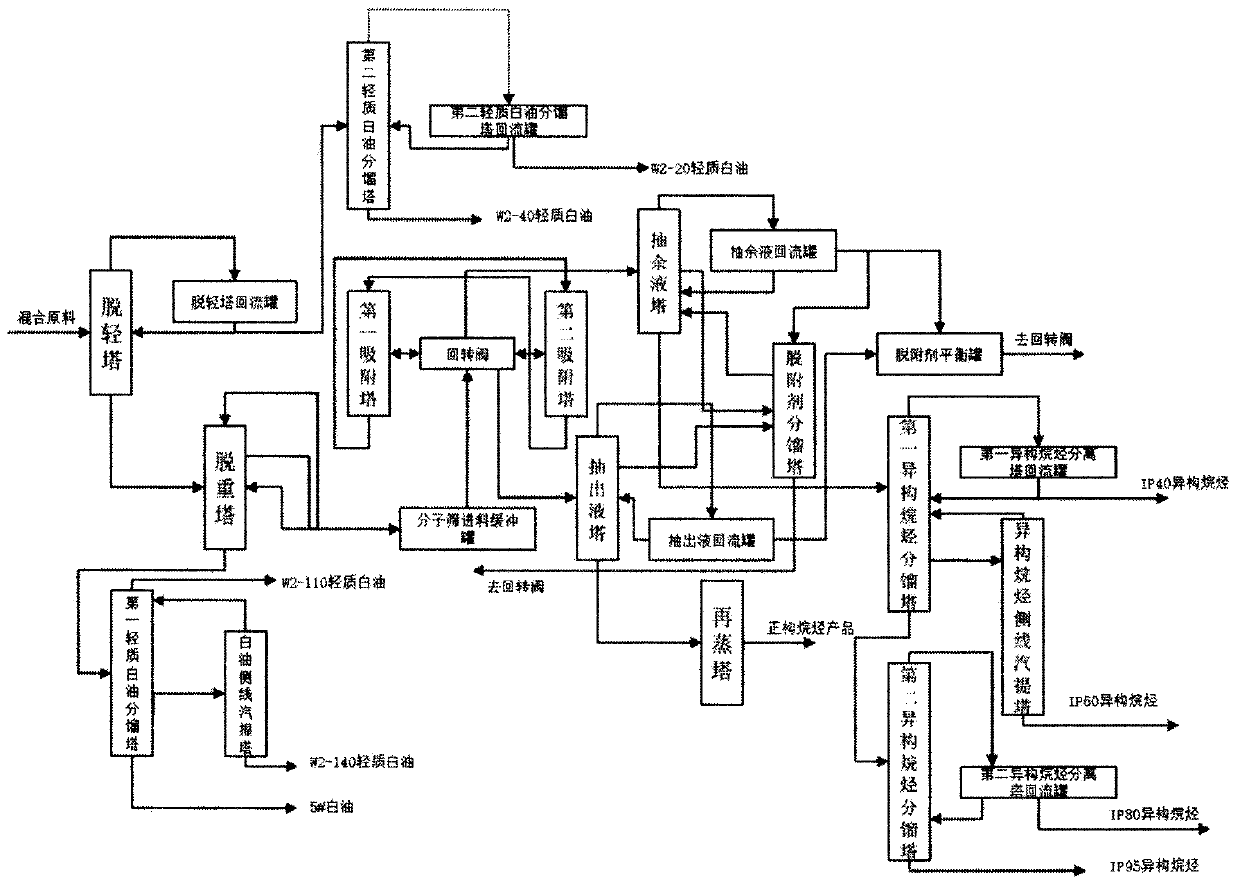

[0056] combine figure 1 Process of the present invention is described:

[0057] In the raw material, the first Fischer-Tropsch crude liquid wax stream accounts for 22.92% Wt in the raw material, and the first Fischer-Tropsch crude liquid wax includes 9.066962% Wt of C5-C9 normal alkanes, 0.201892% Wt of C5-C9 isoparaffins, 47.46498% Wt C10-C13 n-paraffins, 2.015039% Wt C10-C13 isoparaffins, 26.1817% Wt C14-C16 n-paraffins, 1.764391 Wt C14-C16 isoparaffins, 12.06655% Wt C17+ n-paraffins Alkanes, 1.238479% Wt C17+ isoparaffins.

[0058] The second Fischer-Tropsch crude liquid wax stream accounts for 23.20% Wt in the raw material, and the second Fischer-Tropsch crude liquid wax includes C5-C9 normal paraffins of 10.7984425% Wt, C5-C9 isoparaffins of 0.265891% Wt, 47.73631% Wt C10-C13 n-paraffins, 2.036661%Wt C10-C13 isoparaffins, 24.9543185%Wt C14-C16 n-paraffins, 1.6702325%Wt C14-C16 isoparaffins, 11.340289%Wt C17+ n-paraffins, 1. 197856% wt of C17+ isoparaffins.

[0059] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com