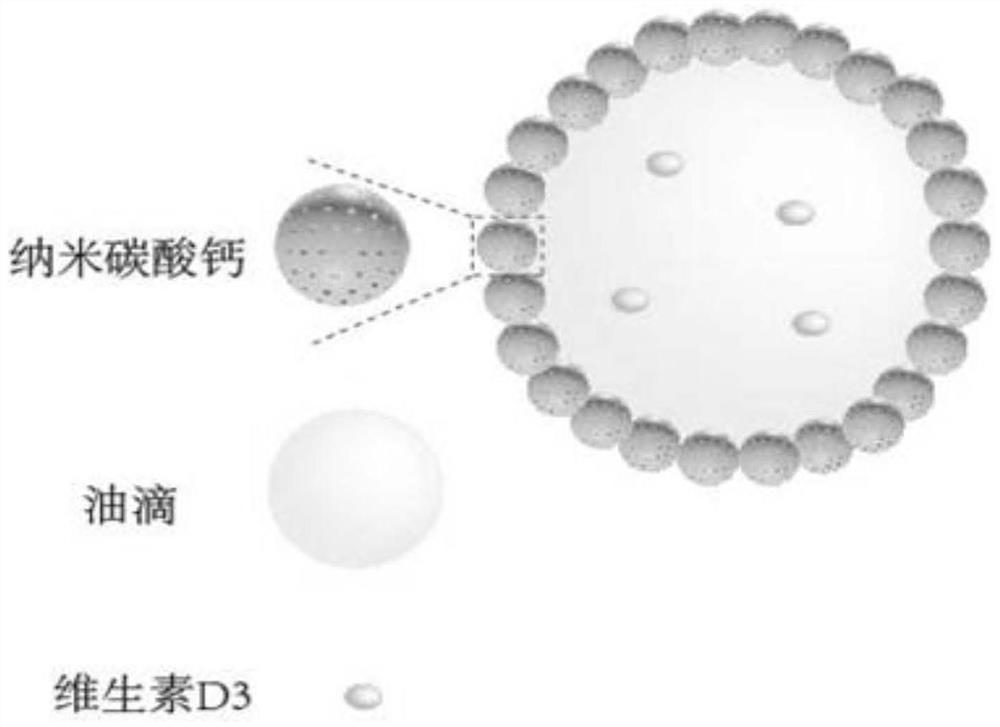

A kind of nano calcium carbonate Pickering emulsion loaded with vitamin D3 and its preparation method and application

A technology of nano-calcium carbonate and Pickering emulsion, which is applied in the fields of food and medicine, can solve problems such as discounting the emulsification performance of nano-calcium carbonate, limiting the application of modified nano-calcium carbonate, and the toxicity of chemical modifiers, so as to improve bioavailability, Reduces the burden on the gastrointestinal tract and has good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] 1. Ingredients

[0064] Nano-calcium carbonate suspension: take food-grade nano-calcium carbonate powder, add water to make a nano-calcium carbonate suspension with a concentration of 50 mg / mL, and set aside;

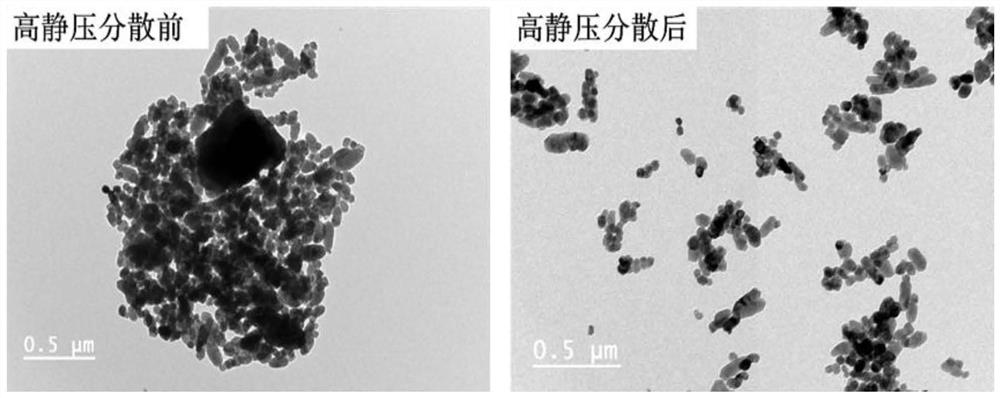

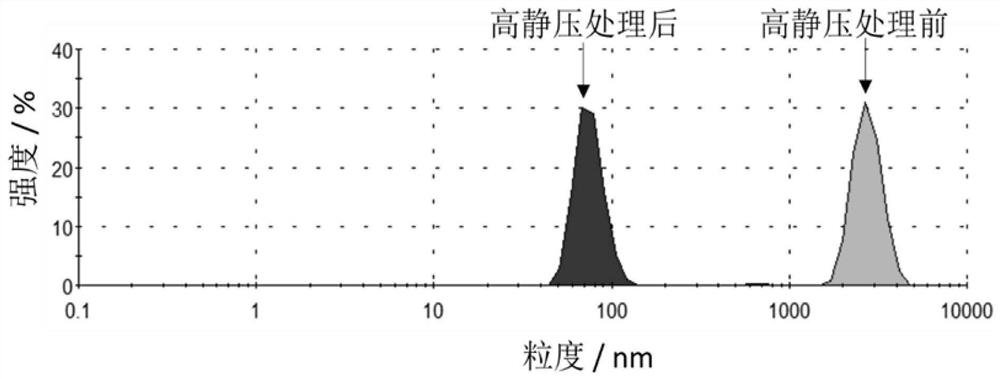

[0065] 2. High static pressure dispersion

[0066] The nano-calcium carbonate suspension in step 1 is placed in a high static pressure device, and the working pressure is maintained for 20 min under the condition of 300 MPa to obtain a nano-calcium carbonate dispersion;

[0067] 3. Vitamin D3 oil solution

[0068] Vitamin D3 oil solution: take food-grade vitamin D3, add it to medium-chain fatty acid solution, stir for 1 hour at room temperature, away from light, at a stirring speed of 200rpm, to completely dissolve vitamin D3, and prepare a 100 IU / mL vitamin D3 oil solution for later use ;

[0069] 4. Preparation of Pickering emulsion

[0070] Mix the nano-calcium carbonate dispersion obtained in step 2 with the vitamin D3 oil solution obtained in step 3 at a...

Embodiment 2

[0087] 1. Ingredients

[0088] Nano-calcium carbonate suspension: take food-grade nano-calcium carbonate powder, add water to make a nano-calcium carbonate suspension with a concentration of 40 mg / mL, and set aside;

[0089] 2. High static pressure dispersion

[0090] With the nano-calcium carbonate suspension in step 1 in the high static pressure equipment, it is kept 30 min under the condition of 250 MPa at working pressure, obtains the nano-calcium carbonate dispersion;

[0091] 3. Vitamin D3 oil solution

[0092] Vitamin D3 oil solution: take food-grade vitamin D3, add it to corn oil, stir at room temperature for 2 h in the dark, at a stirring speed of 300 rpm, to completely dissolve vitamin D3, and prepare a 200 IU / mL vitamin D3 oil solution for later use;

[0093] 4. Preparation of Pickering emulsion

[0094] Mix the nano-calcium carbonate dispersion obtained in step 2 with the vitamin D3 oil solution obtained in step 3 at a volume ratio of 2:8, high-speed shear homog...

Embodiment 3

[0100] 1. Ingredients

[0101] Nano-calcium carbonate suspension: take food-grade nano-calcium carbonate powder, add water to make a nano-calcium carbonate suspension with a concentration of 20 mg / mL, and set aside;

[0102] 2. High static pressure dispersion

[0103] The nano-calcium carbonate suspension in step 1 is kept in a high static pressure device for 30 min at a working pressure of 400 MPa;

[0104] 3. Vitamin D3 oil solution

[0105] Vitamin D3 oil solution: Take food-grade vitamin D3, add it to soybean oil, stir for 3 hours at room temperature, away from light, at a stirring speed of 400rpm, to completely dissolve vitamin D3, and prepare a 50 IU / mL vitamin D3 oil solution for later use;

[0106] 4. Preparation of Pickering emulsion

[0107] Mix the nano-calcium carbonate dispersion obtained in step 2 with the vitamin D3 oil solution obtained in step 3 at a volume ratio of 3:7, and homogenize at high speed for 14 min at a shear rate of 10,000 rpm to obtain nano-ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com