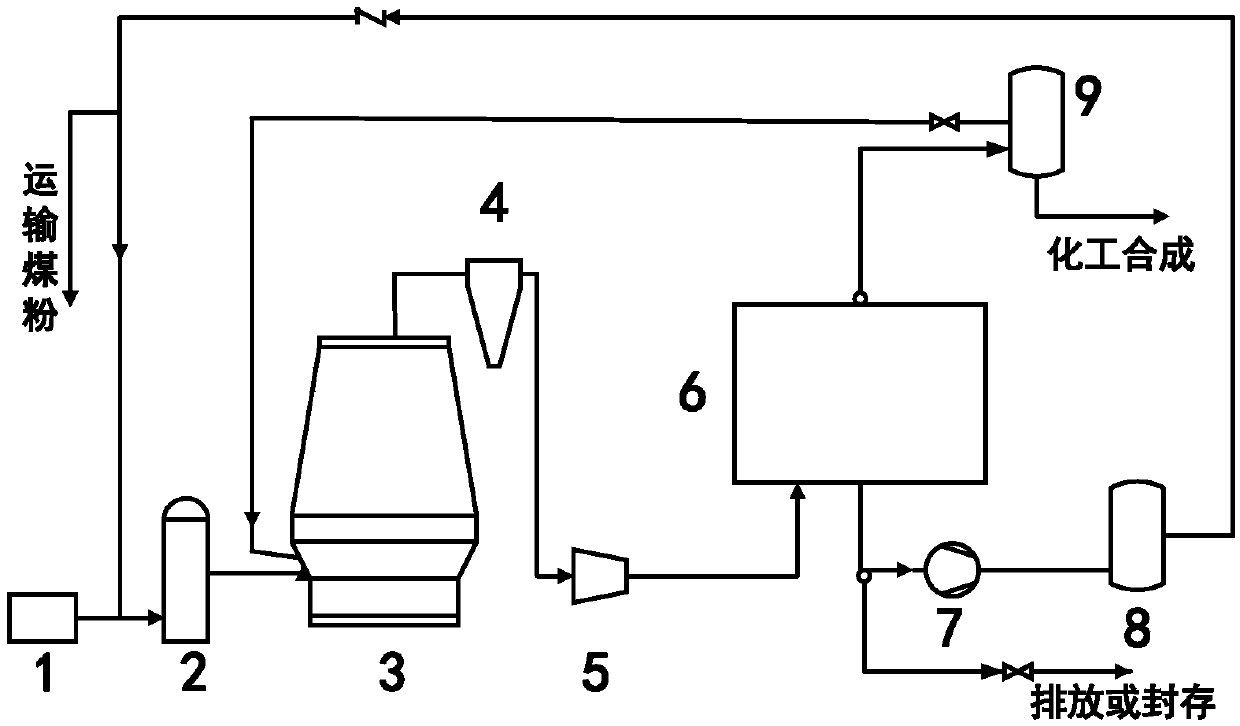

Method and device for simulating pure oxygen iron-making and blast furnace gas recycling

A blast furnace gas and oxygen production device technology, applied in blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems that the molten steel at the bottom cannot form enough agitation, the blast furnace wall is greatly affected, and the amount of gas-supporting gas is small, etc., to achieve separation Low cost, cost-effective and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Blast furnace volume: 2000m 3 ; Use ordinary coal: 400kg / ton of iron, the composition of ordinary coal is shown in Table 1, and the fixed carbon consumption is 298kg / ton of iron. Blast furnace utilization factor: 2.95 tons of iron / (m 3 ·sky). Oxygen consumption: 230m 3 / ton of iron, its composition is as table 2, and the present embodiment attributes the Ar inert gas to N 2 middle. Blast furnace gas output: 2600Nm 3 / ton of iron, its composition is shown in Table 3.

[0060] Table 1 Composition of Common Coal (%)

[0061] C H 2

N 2

O 2

S h 2 o

Ash 74.5 4.2 0.4 3.4 0.5 0.8 16.2

[0062] Table 2 Oxygen Composition (%):

[0063] O 2

N 2 (including N 2 +AR)

90% 10%

[0064] Table 3 Composition of blast furnace gas (%, dry gas)

[0065] CH 4

CO CO 2

H 2

N 2

0.35 48.29 34.26 11.56 5.54

[0066] For every ton of iron produced, the total amount of puri...

Embodiment 2

[0073] Blast furnace volume: 2000m 3 Coal usage: coking coal 200kg / ton of iron, its composition is shown in Table 6; ordinary coal 130kg / ton of iron, its composition is shown in Table 1. The total carbon consumption is 265kg / t iron. Blast furnace utilization factor: 3.25 tons of iron / (m 3 ·sky);

[0074] Table 6 coking coal composition (%)

[0075] C H 2

N 2

O 2

S h 2 o

Ash 83.8 0.3 0.3 3.4 0.5 1.5 14.6

[0076] Oxygen consumption: 190m 3 / ton of iron, its composition is as table 7, the present embodiment attributes the Ar inert gas to N 2 middle.

[0077] Table 7 Oxygen Composition (%):

[0078] O 2

N 2 (including N2+AR)

99% 1%

[0079] Blast furnace gas output: 2250Nm 3 / ton of iron, its composition is shown in Table 3

[0080] Table 8 Composition of blast furnace gas (%, dry gas)

[0081] CH 4

CO CO 2

H 2

N 2

0.38 53.16 38.88 5.43 2.15

[0082] For ...

Embodiment 3

[0089] Blast furnace volume: 2000m 3 , for tempering joint production.

[0090] Common coal is 770kg / ton of iron, and its composition is shown in Table 1; the total carbon consumption is 574kg / ton of iron. Blast furnace utilization factor: 2.95 tons of iron / (m 3 day), by-product pure CO gas 860Nm 3 ;Oxygen consumption: 380m 3 / ton of iron, its composition is shown in Table 2. Blast furnace gas output: 1875Nm 3 / ton of iron, its composition is shown in Table 11.

[0091] Table 11 Composition of blast furnace gas (%, dry gas)

[0092] CH 4

[0093] For every ton of pig iron produced, the total amount of CO product gas after purification is 1215m 3 , its composition is shown in Table 12, and the yield of pure CO is 858m 3 The gas volume per ton can be used for chemical synthesis.

[0094] Table 12 Composition of CO product gas (%)

[0095] CH 4

[0096] For each ton of pig iron produced, CO after purification 2 The total product gas volume is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com