Cellulose-dopamine/carbon nano tube based conductive fiber and preparation method and application thereof

A carbon nanotube and conductive fiber technology, which is applied in the field of cellulose-dopamine/carbon nanotube conductive fibers and their preparation, can solve the problems that affect the commercialization process of CNTs and is difficult to disperse uniformly, and achieves strong practicability and cost. Inexpensive, high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of dopamine-modified cellulose aqueous solution

[0035] Weigh 100 g of carboxymethyl cellulose sodium salt (molecular weight 700 kDa, degree of substitution 0.9), and prepare 0.5 wt % carboxymethyl cellulose aqueous solution. Add 0.96g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride into the above aqueous solution and stir mechanically for 1h, use 0.1mol L -1 Dilute hydrochloric acid to adjust the pH value of the solution to 4.5-5, continue to add 0.58g N-hydroxysuccinimide and 0.95g dopamine hydrochloride, in N 2 Under ambient conditions, mechanically stir for 24 hours at a speed of 1000 rad min -1 . Using a dialysis bag with a molecular weight cut-off of 3kDa, dialyze at room temperature for 5 days, and replace distilled water every 12 hours. Subsequently, a 2wt% DACMC light yellow transparent solution was obtained by suction filtration, and stored in a refrigerator at 4°C.

[0036] (2) Preparation of cellulose-dopamine / carbon nanot...

Embodiment 2

[0042] (1) Preparation of dopamine-modified cellulose aqueous solution

[0043] Weigh 100 g of carboxymethyl cellulose sodium salt (molecular weight 700 kDa, degree of substitution 0.9), and prepare 0.5 wt % carboxymethyl cellulose aqueous solution. Add 0.96g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride into the above aqueous solution and stir mechanically for 1h, use 0.1mol L -1 Dilute hydrochloric acid to adjust the pH value of the solution to 4.5-5, continue to add 0.58g N-hydroxysuccinimide and 0.95g dopamine hydrochloride, in N 2 Under ambient conditions, mechanically stir for 24 hours at a speed of 1000 rad min -1 . Using a dialysis bag with a molecular weight cut-off of 3kDa, dialyze at room temperature for 5 days, and replace distilled water every 12 hours. Subsequently, a 2wt% DACMC light yellow transparent solution was obtained by suction filtration, and stored in a refrigerator at 4°C.

[0044] (2) Preparation of cellulose-dopamine / carbon nanotub...

Embodiment 3

[0051] (1) Preparation of dopamine-modified cellulose aqueous solution

[0052] Weigh 100 g of carboxymethyl cellulose sodium salt (molecular weight 700 kDa, degree of substitution 0.9), and prepare 0.5 wt % carboxymethyl cellulose aqueous solution. Add 0.96g of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride into the above aqueous solution and stir mechanically for 1h, use 0.1mol L -1 Dilute hydrochloric acid to adjust the pH value of the solution to 4.5-5, continue to add 0.58g N-hydroxysuccinimide and 0.95g dopamine hydrochloride, in N 2 Under ambient conditions, mechanically stir for 24 hours at a speed of 1000 rad min -1 . Using a dialysis bag with a molecular weight cut-off of 3kDa, dialyze at room temperature for 5 days, and replace distilled water every 12 hours. Subsequently, a 2wt% DACMC light yellow transparent solution was obtained by suction filtration, and stored in a refrigerator at 4°C.

[0053] (2) Preparation of cellulose-dopamine / carbon nanot...

PUM

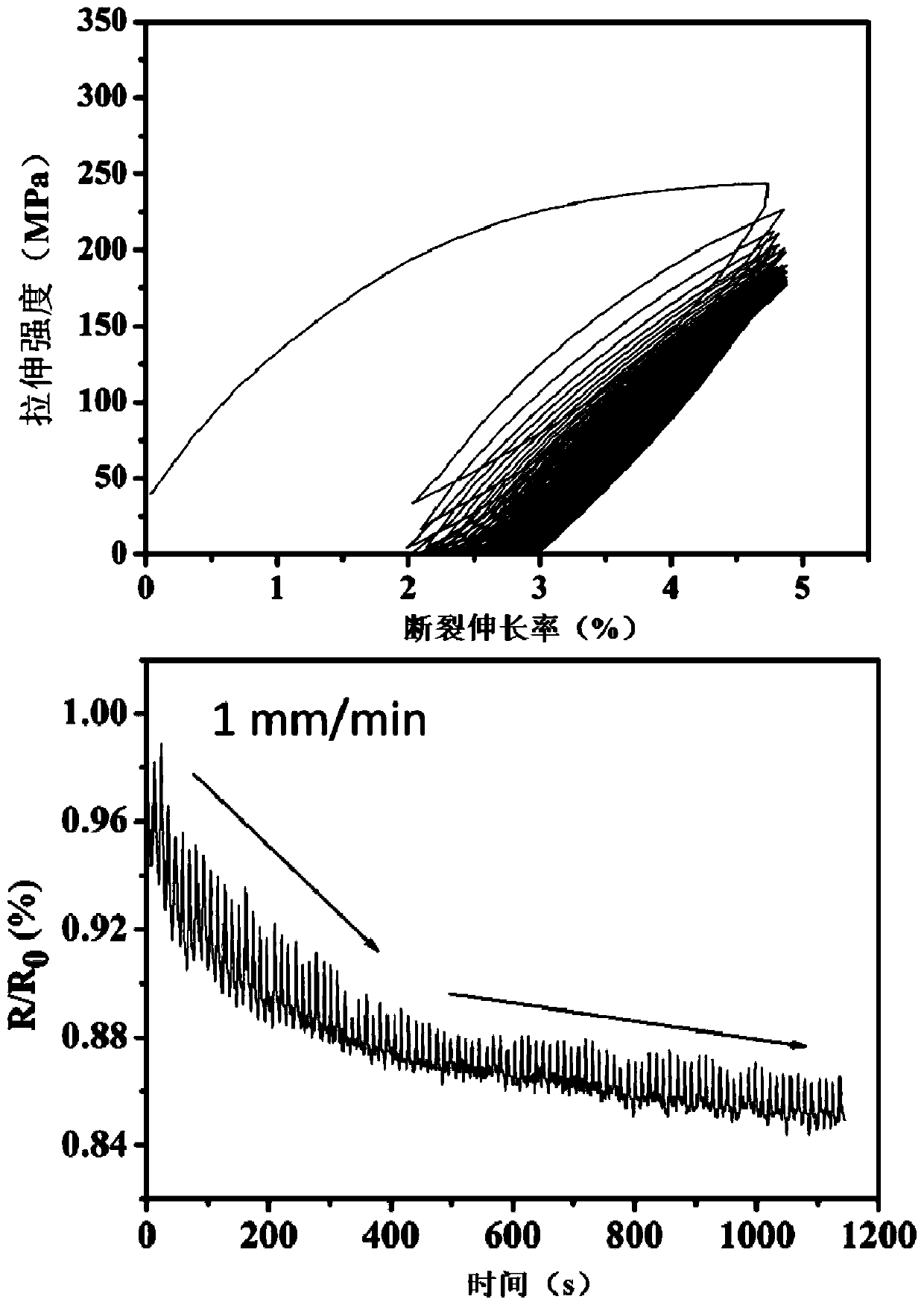

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com