Preparation method of composite wiredrawing protein and product and application thereof

A technology of drawing protein and rice protein, applied in protein food ingredients, protein food processing, application, etc., can solve the problems of overall toughness and insufficient stability of scaffold structure, achieve reasonable amino acid composition, improve water holding capacity, and fill market gaps and defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

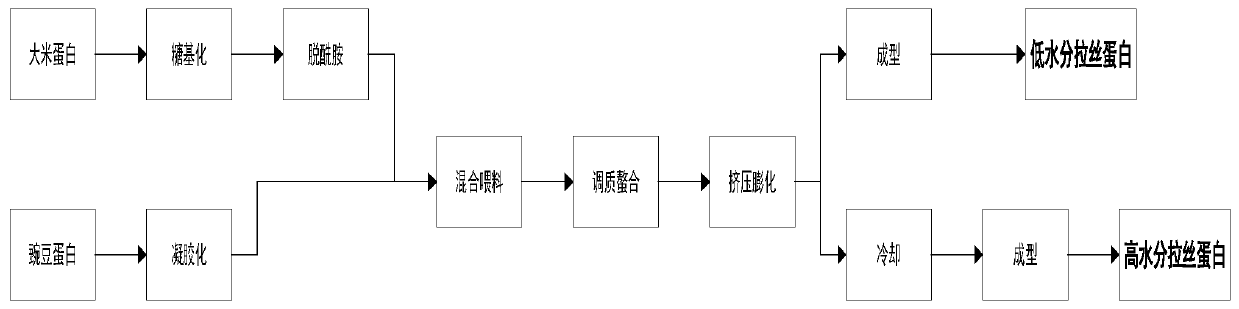

Method used

Image

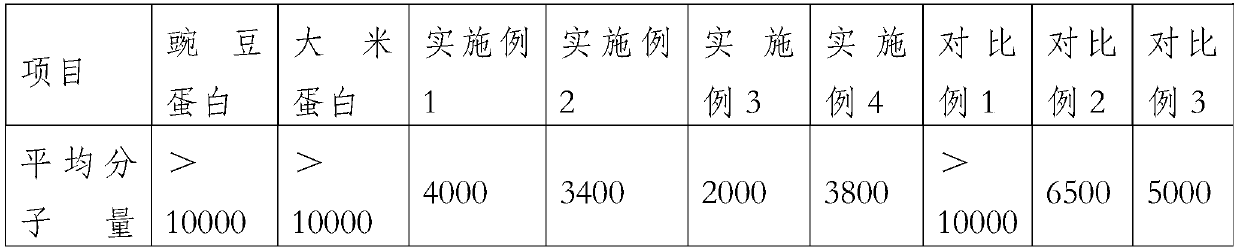

Examples

Embodiment 1

[0040] A method and application of using rice protein and pea protein to prepare composite silk protein, the preparation method comprising the following steps:

[0041] (1) Glycosylation of rice protein: take food-grade rice protein, add 3% seaweed polysaccharide based on the dry matter of rice protein while stirring at 4500r / min, and react for 20 hours at a moisture content of 50% and a temperature of 45°C , to obtain the Maillard grafted rice protein product;

[0042] (2) Rice protein deamidation: the grafted product that step (1) obtains, adds the compound protease (trypsin: carboxypeptidase: papain mass ratio=2:2:1) of 0.1% in terms of rice protein dry matter , pass into ozone (8L / min) synergistic reaction, control moisture content 40%, under the condition of pH8, temperature 50 ℃, after 2500r / min stirring enzymolysis 4h, obtain the rice protein after deamidation;

[0043] (3) Pea protein gelation: Take food-grade pea protein, add 1% chitosan based on the dry matter of pe...

Embodiment 2

[0052] A method and application of using rice protein and pea protein to prepare composite silk protein, the preparation method comprising the following steps:

[0053] (1) Glycosylation of rice protein: take food-grade rice protein, and while stirring at 3500r / min, add 10% seaweed polysaccharide based on the dry matter of rice protein, and react for 10 hours at a moisture content of 60% and a temperature of 50°C , to obtain the Maillard grafted rice protein product;

[0054] (2) rice protein deamidation: the grafted product that step (1) obtains, adds the composite protease (aminopeptidase: alkaline protease: ficin: bromelain mass ratio=1.5: 1.5:0.5:0.5), feed ozone (4L / min) for synergistic reaction, control the moisture content to 50%, under the conditions of pH 9 and temperature 60°C, stir at 3500r / min for 2 hours to obtain deamidated rice protein ;

[0055] (3) Pea protein gelation: Take food-grade pea protein, add 2% chitosan based on the dry matter of pea protein, stir...

Embodiment 3

[0064] A method and application of using rice protein and pea protein to prepare composite silk protein, the preparation method comprising the following steps:

[0065] (1) Glycosylation of rice protein: take food-grade rice protein, while stirring at 5000r / min, add 15% seaweed polysaccharide based on the dry matter of rice protein, and react for 6 hours at a moisture content of 78% and a temperature of 58°C , to obtain the Maillard grafted rice protein product;

[0066] (2) rice protein deamidation: the grafted product that step (1) obtains, adds the composite protease (aminopeptidase: cathepsin: alkaline protease: bromelain: subtilisin quality) of 3% in terms of rice protein dry matter Ratio=2:2:3:0.5:0.5), ozone (6L / min) was introduced into the synergistic reaction, the water content was controlled to 65%, and under the conditions of pH 10 and temperature 70°C, 4000r / min stirring enzymolysis for 3h, the obtained Rice protein after deamidation;

[0067] (3) Pea protein gel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median diameter | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com