Fermented fish sauce with fruity flavor and without additional salt and preparation method of fermented fish sauce

A technology for fermenting fish sauce and flavor, applied in the directions of bacteria, yeast-containing food ingredients, Streptococcus/Lactococcus, etc. used in food preparation, can solve the problems of unsuitable growth of microorganisms and high salinity of products, and avoid volatile nitrogen and sulfur compounds, reducing aldehydes, improving acceptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

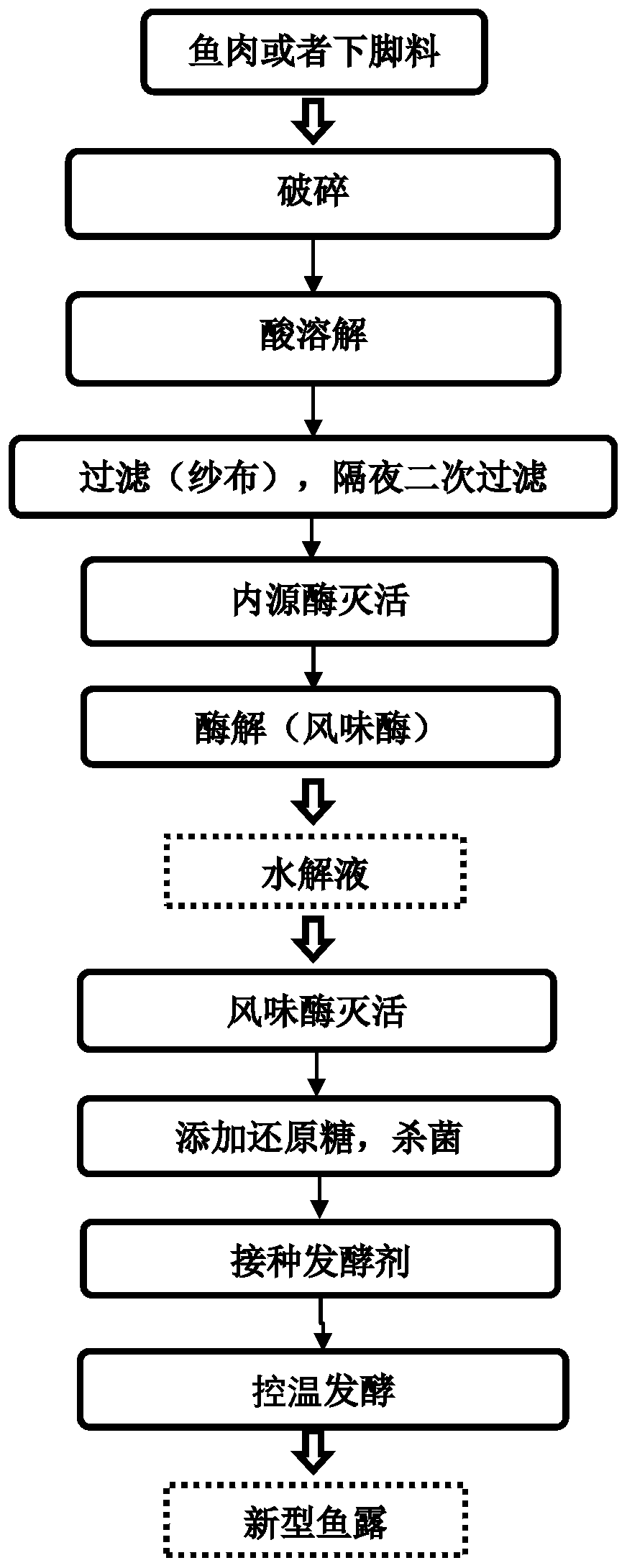

Method used

Image

Examples

Embodiment 1

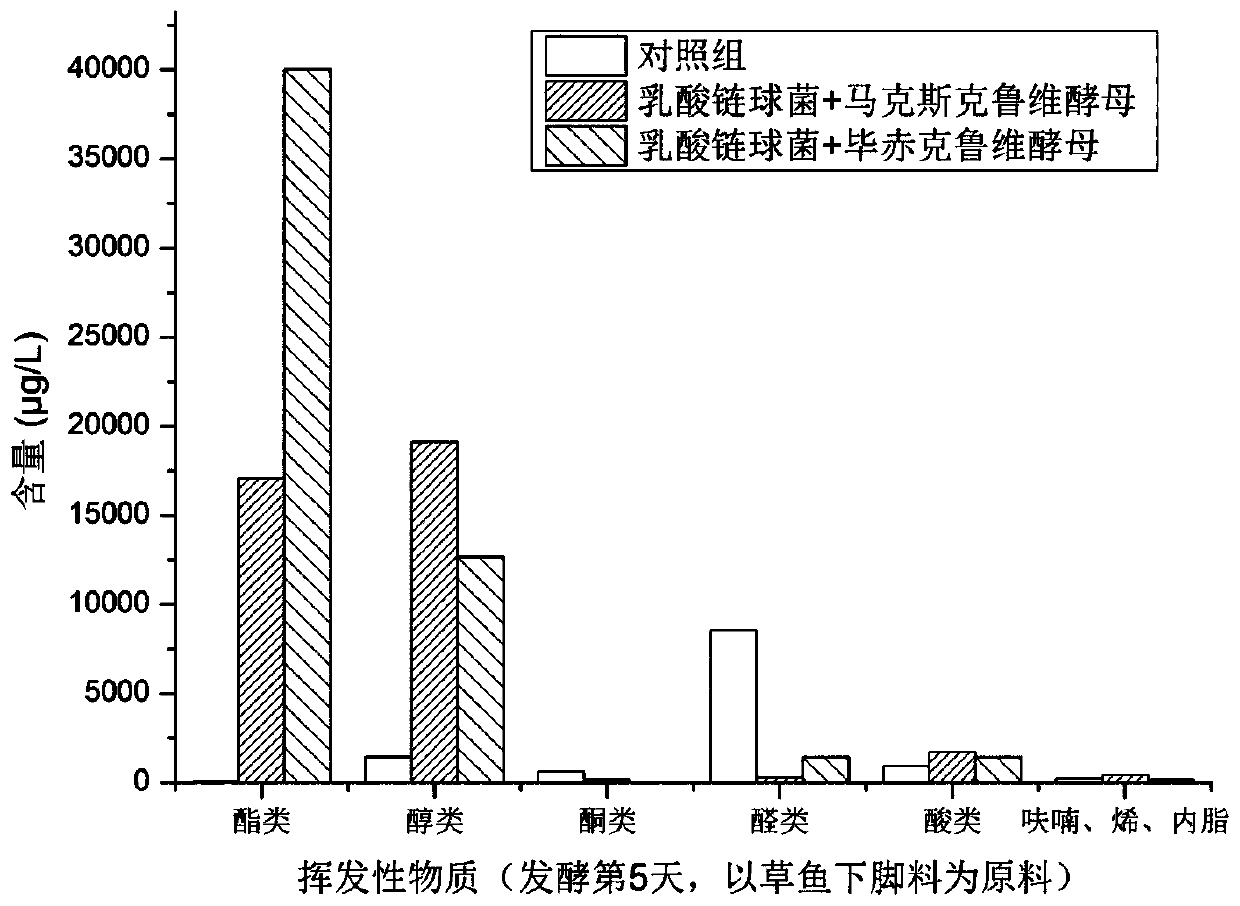

[0032] Cut the grass carp meat into pieces and mince or cut and mix the leftovers such as fish heads, fish bones, and fish tails; add distilled water (w:v=1:6) to dissolve the broken fish or leftovers, and stir evenly. The pH was adjusted to 3.0 with 90% lactic acid. Use gauze to filter the undissolved residue, place the filtrate at 0-4°C, and perform secondary filtration overnight to remove the fish fat on the surface of the filtrate. Heat the above filtrate at 80-85°C for 30 min to inactivate endogenous enzymes, and cool to room temperature. Adjust the filtrate after secondary filtration to pH 6.0, add 0.5% (w / v) flavor enzyme (protease and peptidase mixture, from Aspergillus oryzae, ≥500U / g), keep it in a water bath at 50°C for 3h; The solution was heated at 80-85°C for 30 minutes to inactivate the added protease; 2% (w / v) glucose was added to the inactivated hydrolyzate and sterilized at 80-85°C for 30 minutes; The activated Lactococcus lactis and Kluyveromyces marxianus...

Embodiment 2

[0034] Use silver carp fish meat to be cut into pieces and minced or scraps such as fish heads, fish bones, and fish tails to be chopped and crushed; add distilled water (w:v=1:6) to dissolve the broken fish or scraps, and stir evenly. Use 90% lactic acid to adjust the pH to 3.0; use gauze to filter the undissolved residue, place the filtrate at 0-4°C, and perform secondary filtration overnight to remove the fish fat on the surface of the filtrate; Heat at 85°C for 30min to inactivate endogenous enzymes, cool to room temperature; adjust the filtrate after secondary filtration to pH 6.0, add 0.5% (w / v) flavor enzyme (protease and peptidase mixture, From Aspergillus oryzae, ≥500U / g), incubate at 50°C for 3 hours in a water bath; heat the above enzymatic hydrolysis solution at 80-85°C for 30 minutes to inactivate the added protease; add 2% to the inactivated hydrolyzate (w / v) glucose, and sterilized at 80-85°C for 30 minutes; the activated Lactococcus lactis and Pichia kluyveri (...

Embodiment 3

[0036]Cut the carp meat into pieces and mince or chop and break the leftovers such as fish heads, fish bones, and fish tails; add distilled water (w:v=1:6) to dissolve the broken fish or leftovers, and stir evenly. Use 90% lactic acid to adjust the pH to 3.0; use gauze to filter the undissolved residue, place the filtrate at 0-4°C, and perform secondary filtration overnight to remove the fish fat on the surface of the filtrate; put the above-mentioned filtrate at 80-85 Heated at ℃ for 30 min to inactivate endogenous enzymes, and cooled to room temperature; the filtrate after secondary filtration was adjusted to pH 6.0, and 0.5% (w / v) of flavor enzymes (protease and peptidase mixture from Aspergillus oryzae, ≥500U / g), in a water bath at 50°C for 3h; heat the above enzymolysis solution at 80-85°C for 30min to inactivate the added protease; add 2% ( w / v) glucose, and sterilized at 80-85°C for 30 minutes; the activated Lactococcus lactis and Kluyveromyces marxianus (concentrations...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com