Twisted nano strip-shaped Co-Fe-B catalyst as well as preparation method and application thereof

A co-fe-b, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of limited reserves, general catalytic performance and high cost and other problems, to achieve the effect of reducing preparation cost, low investment cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Weigh 1.4010g ferrous sulfate heptahydrate and 1.4055g cobalt sulfate heptahydrate and ultrasonically dissolve them in 70mL deionized water to form solution A; weigh 4.5042g glycine and dissolve them in 20mL deionized water to form solution B; Mix and magnetically stir for 1 hour to form solution C; dissolve 3.8g of sodium hydroxide in 10mL of deionized water to form solution D; titrate solution D into solution C to obtain solution E; add 2.7463g of sodium borohydride to solution E, A brown solution F is formed; add nickel foam into the brown solution F, and react for 5 minutes. After the reaction, take the foam nickel out of solution F, wash and dry the obtained black solution with an ethanol solution consisting of 20 mL of absolute ethanol and 10 mL of water, and then dry it. The substance is the target product CoFeB catalyst.

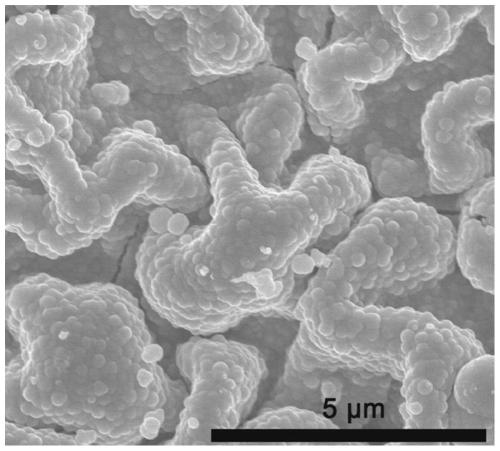

[0050] see figure 1 As shown, it can be seen from the SEM picture that the surface of the CoFeB catalyst has a twisted ribbon structure, and...

Embodiment 2

[0052] Weigh 1.4010g ferrous sulfate heptahydrate and 0.5560g cobalt sulfate heptahydrate and ultrasonically dissolve them in 70mL deionized water to form solution A; weigh 4.5042g glycine and dissolve them in 20mL deionized water to form solution B; Mix and magnetically stir for 1 hour to form solution C; dissolve 3.8g of sodium hydroxide in 10mL of deionized water to form solution D; titrate solution D into solution C to obtain solution E; add 2.7463g of sodium borohydride to solution E, A brown solution F is formed; add the foam sponge to the brown solution F and react for 5 minutes. After the reaction, take the foam copper out of the solution F, wash and dry the obtained black The substance is the target product Co 5 Fe 2 B catalyst.

[0053] It is determined by experiments that the average particle diameter of the surface particles of the twisted ribbon structure exhibited by the catalyst is 180nm.

Embodiment 3

[0055] Weigh 1.4010g ferrous sulfate heptahydrate and 0.2811g cobalt sulfate heptahydrate and ultrasonically dissolve them in 70mL deionized water to form solution A; weigh 4.5042g glycine and dissolve them in 20mL deionized water to form solution B; Mix and magnetically stir for 1 hour to form solution C; dissolve 3.8g of sodium hydroxide in 10mL of deionized water to form solution D; titrate solution D into solution C to obtain solution E; add 6.8094g of sodium borohydride to solution E, A brown solution F is formed; add nickel foam into the brown solution F, and react for 5 minutes. After the reaction, take the foam nickel out of solution F, wash and dry the obtained black solution with an ethanol solution consisting of 20 mL of absolute ethanol and 10 mL of water, and then dry it. The substance is the target product Co 5 FeB catalyst.

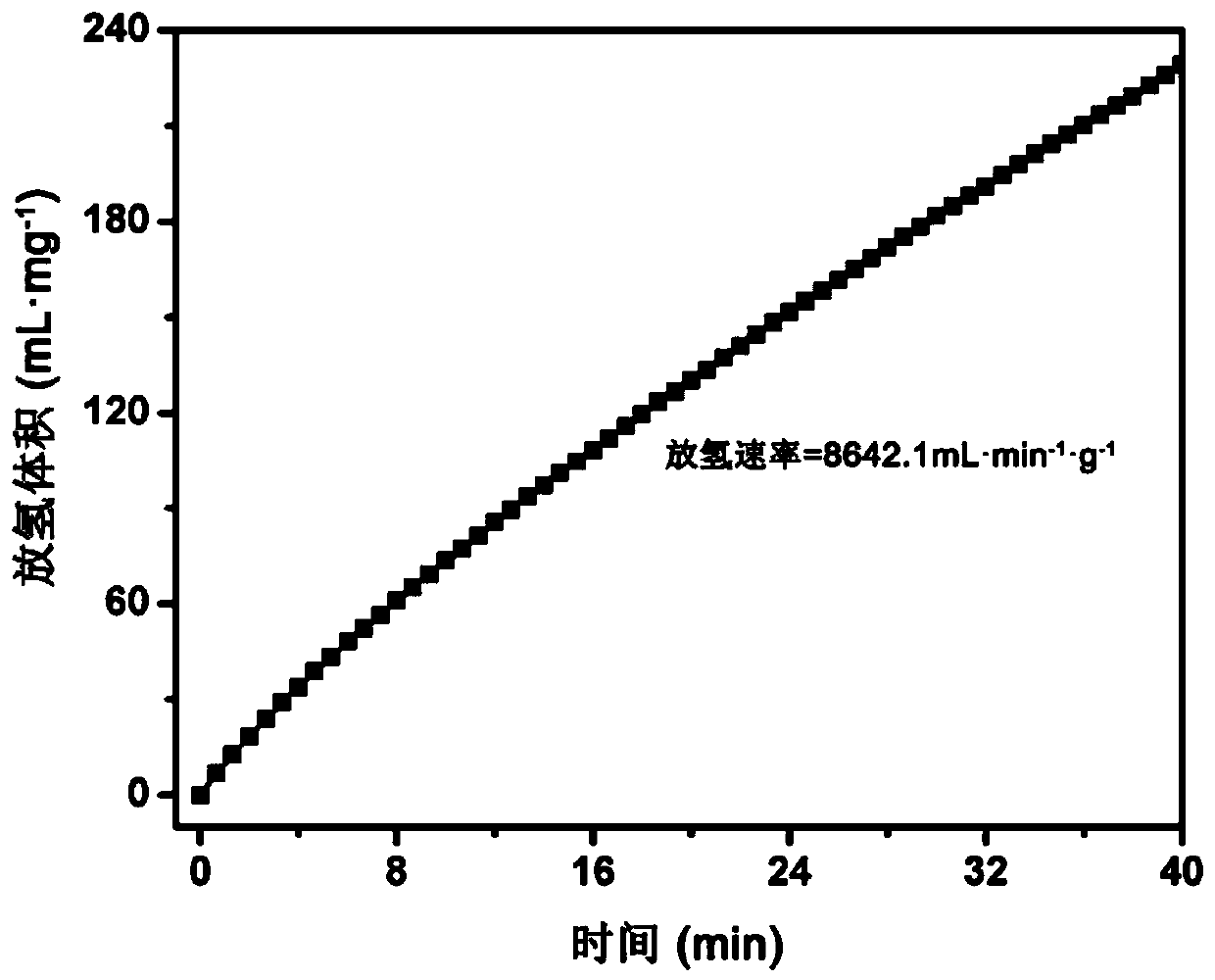

[0056] see figure 2 As shown, the catalyst catalyzes the hydrolysis of sodium borohydride to produce hydrogen at a room temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com