Flotation process for efficiently recovering lead, zinc and sulfur in multi-metal sulfide ore

A polymetallic and sulfide ore technology, applied in flotation, solid separation, etc., can solve the problems of high cost of ore dressing, and achieve the effects of reducing hidden dangers in production safety, saving costs, and reducing the number of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

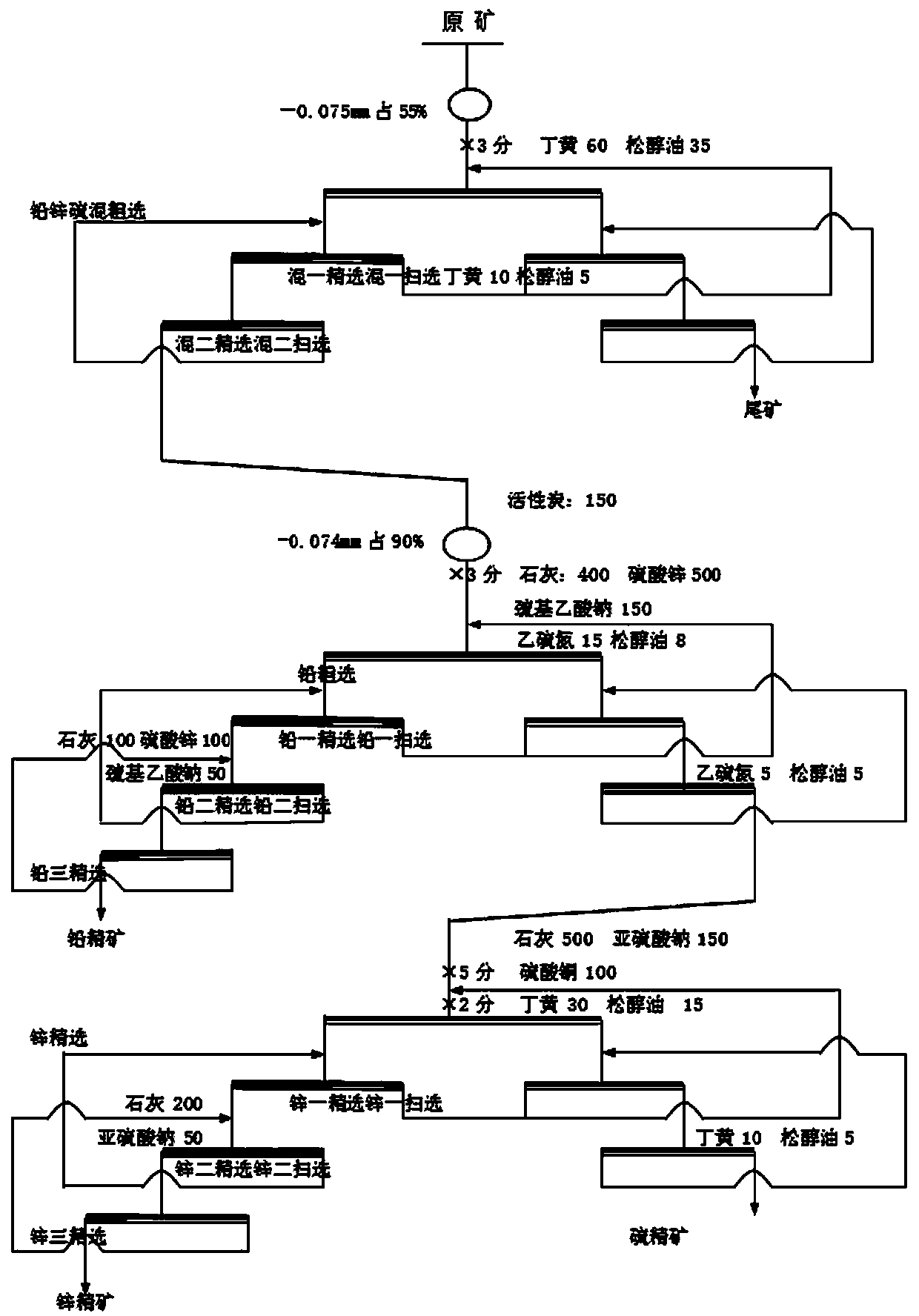

[0035] A lead-zinc mine in Liaoning, the test sample contains 2.22% lead, 1.63% zinc, 7.89% sulfur, and 53.50g / t silver. The mixed flotation of lead, zinc, and sulfur is used. The technological process of zinc produces lead concentrate, zinc concentrate, sulfur concentrate, and comprehensively recovers silver minerals. On-site production process flow and process conditions figure 1 As shown, the production process conditions are: under the condition of no regulator, use a single butyl xanthate to collect lead, zinc, and sulfur, and after the mixed concentrate is regrinded, use activated carbon to remove the drug, zinc sulfate + lime + sodium thioglycolate Inhibit sphalerite and pyrite, ethionite to capture lead minerals, lead tail with copper sulfate to activate zinc minerals, lime + sodium sulfite to inhibit pyrite, butyl xanthate to capture zinc minerals, zinc tail is sulfur concentrate . The small-scale closed-circuit test has obtained relatively ideal beneficiation indic...

Embodiment 2

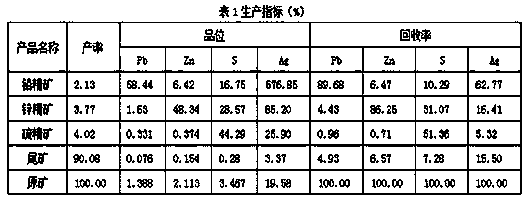

[0037]In a lead-zinc-silver mine in Inner Mongolia, the test sample contained 1.39% lead, 2.12% zinc, 3.47% sulfur, and 19.65g / t silver. The mixed flotation of lead, zinc, and sulfur was used to float in order, followed by refining and regrinding. Process flow of lead and zinc. The mixed flotation of lead, zinc and sulfur adopts a process of one roughing, three refining and three sweeping; after the lead-zinc-sulfur mixed concentrate is regrinded, the process of floating lead first adopts one roughing, three refining and two sweeping; Three precision and two sweep process. Flotation produces lead concentrate, zinc concentrate, sulfur concentrate, and comprehensive recovery of silver minerals. The production process conditions are: under the conditions that the grinding fineness -0.074mm accounts for 60%, the dosage of butyl xanthate is 50g / t, and the dosage of terpineol oil is 30g / t, the mixed flotation of lead, zinc and sulfur is carried out. Obtain lead-zinc-sulfur mixed c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com