Anti-cracking recycled concrete and preparation method thereof

A recycled concrete and anti-cracking technology, applied in the field of concrete, can solve the problems of reduced service life, easy cracking of concrete, and decreased durability of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

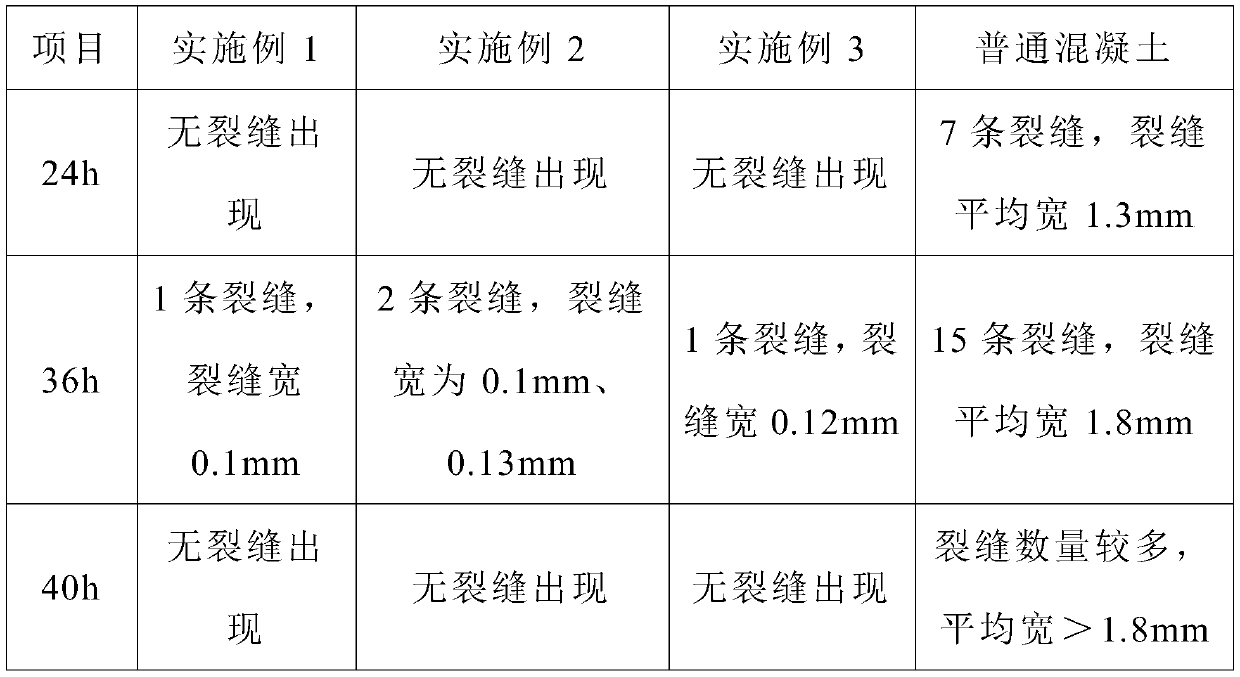

Examples

Embodiment 1

[0053] S1: Prepare materials:

[0054] S2: Preparation of azide cyclodextrin:

[0055] Take β-cyclodextrin, recrystallize 3 times in aqueous solution, filter, dry in vacuum for 24 hours, then place in sodium hydroxide solution, stir for 10 minutes, slowly add acetonitrile solution of p-toluenesulfonyl chloride dropwise, and adjust the pH during the dropwise addition To 13, react for 3 hours, then adjust the pH to 7, add methanol, stir for 30 minutes, filter, take the filtrate, stand at -8°C for 24 hours, collect the precipitate, pass through a G25 gel column to desalt, freeze-dry to reach sulfonated cyclodextrin ;

[0056] Dissolve sulfonated cyclodextrin and N,N-dimethylformamide solution, stir for 10 minutes, refrigerate and vacuum 3 times, then add sodium azide, heat up to 60°C, stir for 48 hours, collect the product, freeze-dry , to obtain azide cyclodextrin;

[0057] S3: Preparation of modified nanotubes:

[0058] Take bromoacetyl bromide and dissolve it in dichlorome...

Embodiment 2

[0070] S1: Prepare materials:

[0071] S2: Preparation of azide cyclodextrin:

[0072] Take β-cyclodextrin, recrystallize 3 times in aqueous solution, filter, dry in vacuum for 24 hours, then place in sodium hydroxide solution, stir for 13 minutes, slowly add acetonitrile solution of p-toluenesulfonyl chloride dropwise, and adjust the pH during the dropwise addition To 13, react for 3.5 hours, then adjust the pH to 7, add methanol, stir for 35 minutes, filter, take the filtrate, stand at -8°C for 28 hours, collect the precipitate, pass through a G25 gel column to desalt, freeze-dry to achieve sulfonated cyclopaste Refined;

[0073] Dissolve sulfonated cyclodextrin and N,N-dimethylformamide solution, stir for 12 minutes, refrigerate and vacuum 3 times, then add sodium azide, heat up to 63°C, stir for 49 hours, collect the product, freeze-dry , to obtain azide cyclodextrin;

[0074] S3: Preparation of modified nanotubes:

[0075] Take bromoacetyl bromide and dissolve in dich...

Embodiment 3

[0087] S1: Prepare materials:

[0088] S2: Preparation of azide cyclodextrin:

[0089] Take β-cyclodextrin, recrystallize 3 times in aqueous solution, filter, dry in vacuum for 24 hours, then place in sodium hydroxide solution, stir for 15 minutes, slowly add acetonitrile solution of p-toluenesulfonyl chloride dropwise, and adjust the pH during the dropwise addition To 13, react for 4 hours, then adjust the pH to 7, add methanol, stir for 40 minutes, filter, take the filtrate, stand at -8°C for 30 hours, collect the precipitate, pass it through a G25 gel column to desalt, freeze-dry to reach sulfonated cyclodextrin ;

[0090] Dissolve sulfonated cyclodextrin and N,N-dimethylformamide solution, stir for 15 minutes, refrigerate and vacuum 4 times, then add sodium azide, heat up to 65°C, stir for 50 hours, collect the product, freeze-dry , to obtain azide cyclodextrin;

[0091] S3: Preparation of modified nanotubes:

[0092] Take bromoacetyl bromide and dissolve it in dichlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com