Large-batch manufacturing method and application of polyacrylamide gel films of in-vitro cell culture substrate materials with different hardness

A polyacrylamide gel, in vitro cell culture technology, used in general culture methods, cell culture supports/coatings, tissue culture, etc., can solve problems such as being unsuitable for large sample research, difficult to directly cut, and edge wrinkles. , to achieve the effect of easy storage and transportation, simple operation and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] 2. Preparation of Hydrophobic Glass Slides

[0043] Put 3-5 drops of hydrophobic solution on the glass plate, then wipe with tissue paper to make the hydrophobic coating even, let it air dry.

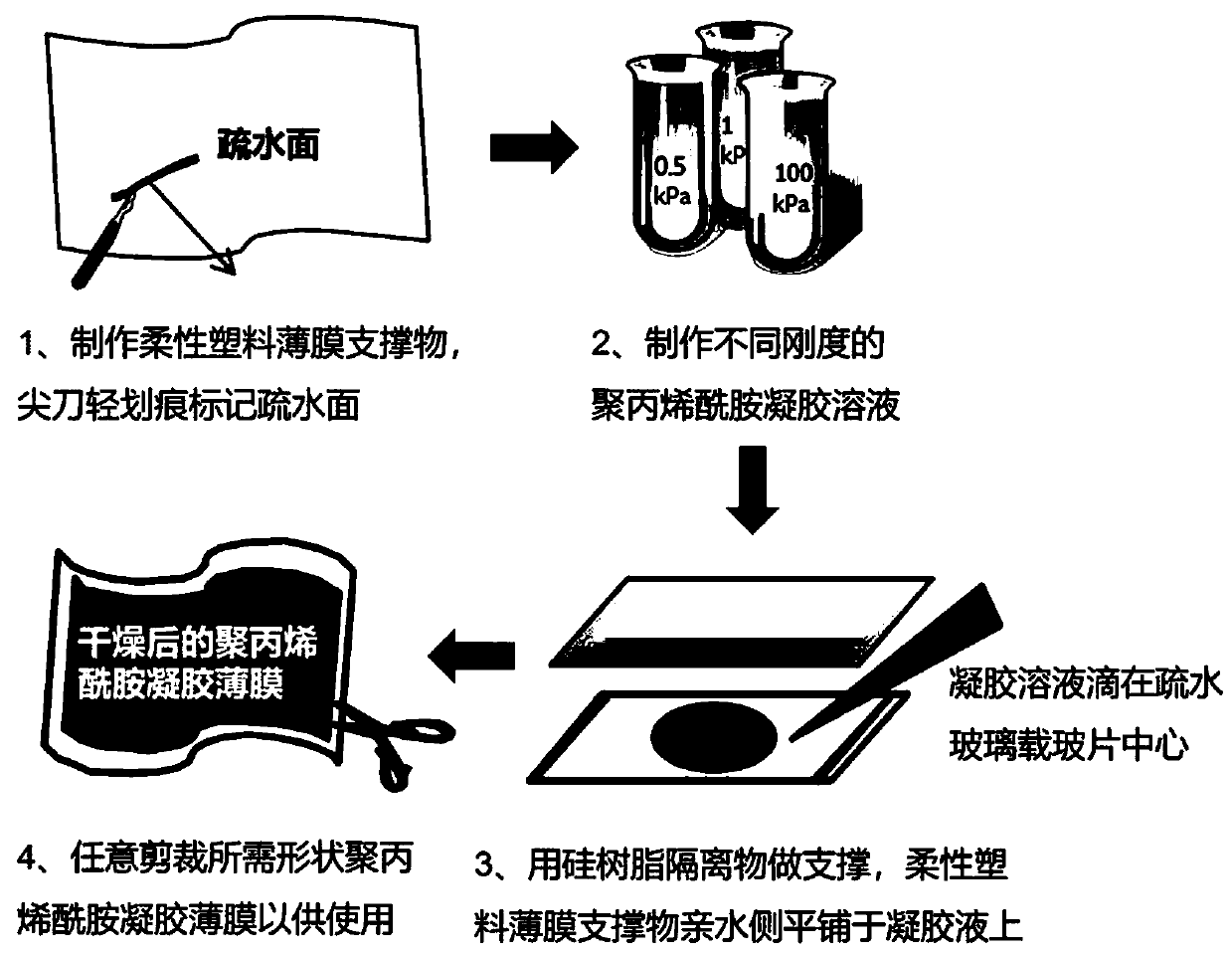

[0044] 3. Preparation of Flexible Plastic Film Supports

[0045] (1) Drop 3-5 drops of hydrophobic solution on one side of the flexible plastic film support, then wipe it with tissue paper to make the hydrophobic coating uniform, and let it air dry. The flexible plastic film support was then cut to match the size of the previous hydrophobic glass slide.

[0046] (2) Gently scrape the surface of the flexible plastic film support with a sharp tool (such as a scalpel) to mark the hydrophobic side, and once completely transparent and dry, the polyacrylamide gel permanently adheres to the hydrophilic side of the plastic film support , the scratches will help distinguish which side of the flexible plastic film support contains the gel. (2) Preparation method of polyacrylamide gel fi...

Embodiment 1

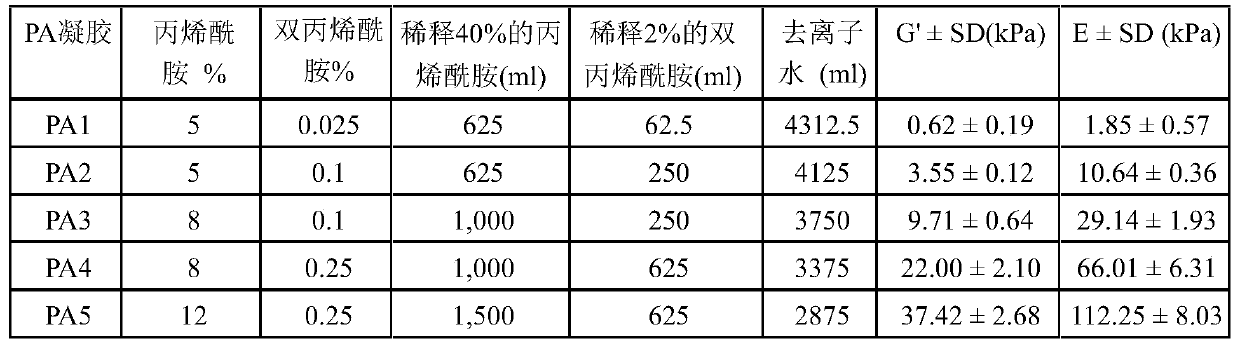

[0072] A method for mass production of in vitro cell culture base materials with different hardnesses. Ten copies of polyacrylamide gel films with a hardness of Young's modulus E=29.14±1.93 for use in 60mm petri dishes are produced.

[0073] 1. Prepare 4972.5 μl of polyacrylamide precursor solution according to the ratio of PA3 in Table 1, put it into a 50ml conical tube, open the lid, and put it in a degassing chamber for degassing for 30 minutes.

[0074] 2. Add 25 µl of 10% w / v ammonium persulfate (see 1(3)) to make a final ammonium persulfate concentration of 0.05%.

[0075] 3. Add 2.5 μl N, N, N', N'-tetramethylethylenediamine (TEMED, M r 116.24 g / mol), so that the final TEMED concentration reached 0.5%.

[0076] 4. Gently pipette the mixed solution up and down for 3 to 5 times, do not vortex and shake well to avoid oxygen diffusion into the gel solution.

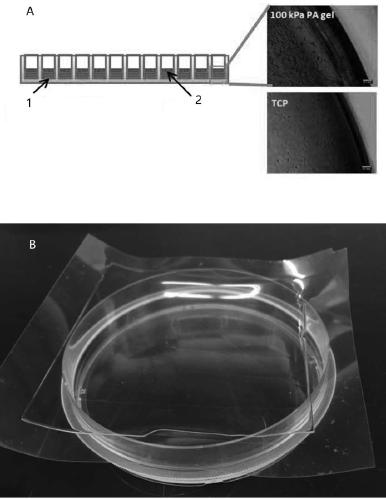

[0077] 5. Use 10 60mm*60mm hydrophobic glass slides as bottom supports, and use 0.5mm silicone resin spacers as s...

Embodiment 2

[0085] A method for mass production of in vitro cell culture base materials with different hardnesses. Ten copies of polyacrylamide gel films with a hardness of Young's modulus E=1.85±0.57 are prepared for 60mm petri dishes.

[0086]1. Prepare 4972.5 μl of polyacrylamide precursor solution according to the ratio of PA1 in Table 1, put it into a 50ml conical tube, open the lid, and put it in a degassing chamber for 30 minutes to degas.

[0087] 2. Add 25 µl of 10% w / v ammonium persulfate (see 1(3)) to make a final ammonium persulfate concentration of 0.05%.

[0088] 3. Add 2.5 μl N, N, N', N'-tetramethylethylenediamine (TEMED, M r 116.24 g / mol), so that the final TEMED concentration reached 0.5%.

[0089] 4. Gently pipette the mixed solution up and down for 3 to 5 times, do not vortex and shake well to avoid oxygen diffusion into the gel solution.

[0090] 5. Use 10 60mm*60mm hydrophobic glass slides as bottom supports, and use 0.5mm silicone resin spacers as support around ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com