Quick-flowing underfill adhesive capable of being cured at low temperature and preparation method thereof

An underfill and adhesive technology, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of other peripheral components falling off, cumbersome rework process, chip component failure, etc., to reduce the cost of rework, Low rework and scrap rate, and the effect of reducing thermal damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

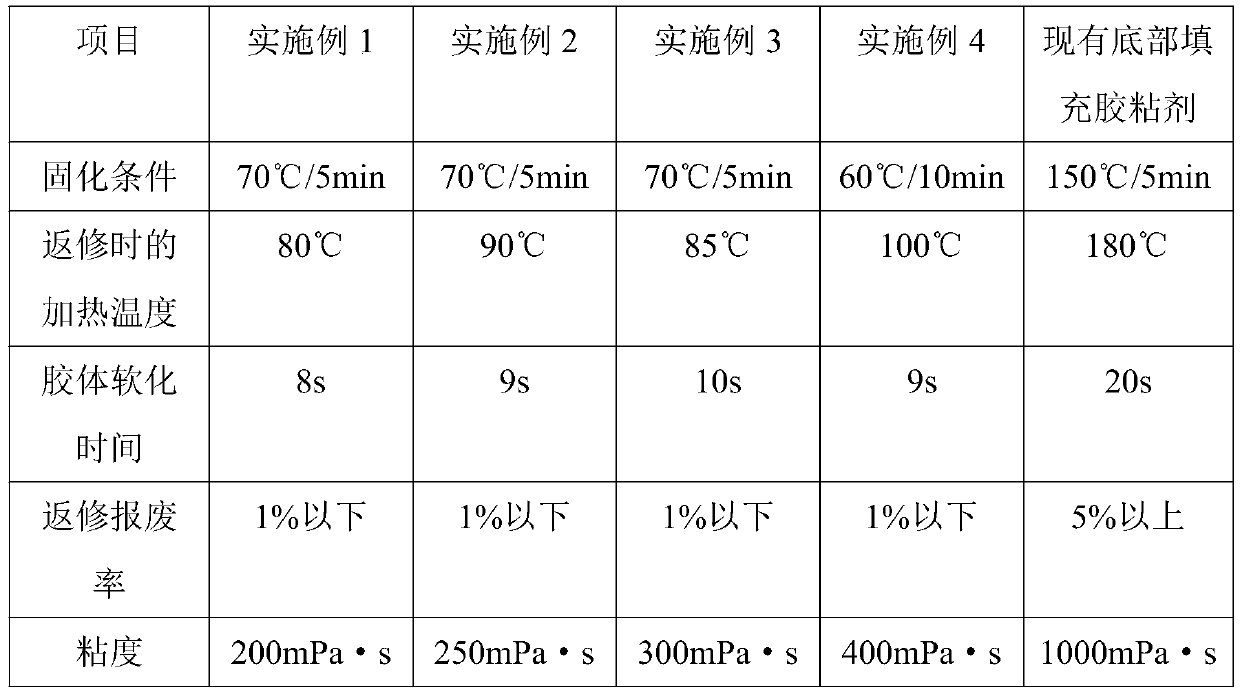

Examples

Embodiment 1

[0034] This embodiment provides a fast-flowing underfill adhesive that can be cured at low temperature, including 45 parts of epoxy resin with core layer-shell layer structure, 20 parts of curing agent, 10 parts of latent curing accelerator, 20 parts of filler, and surfactant 1 part, 1 part of coupling agent, the core layer is high temperature curing amine compound, the shell layer is low temperature curing epoxy compound, the glass transition temperature of high temperature curing amine compound is higher than the glass transition temperature of low temperature curing epoxy compound . Specifically, the core layer is amine-modified polymethyl methacrylate rubber, the shell layer is bisphenol F epoxy resin, alicyclic epoxy resin and epoxidized phenol resin, and the liquid aromatic amine curing agent is 3 -3'-diethyl-4,4'-diaminediphenylmethane, the latent curing accelerator is 2-phenyl-4,5-dimethylolimidazole, the filler is spherical silica, spherical The particle size of type...

Embodiment 2

[0041] This embodiment provides a fast-flowing low-temperature-curable underfill adhesive, including 50 parts of epoxy resin with core layer-shell layer structure, 10 parts of curing agent, 15 parts of latent curing accelerator, 10 parts of filler, and surfactant 1.5 parts, 1 part of coupling agent, 3 parts of toner, 1 part of ion adsorbent, the core layer is high temperature curing amine compound, the shell layer is low temperature curing epoxy compound, the glass transition temperature of high temperature curing amine compound is high The glass transition temperature of epoxy compounds that cure at low temperatures. Specifically, the core layer is amine-modified polybutylacrylate rubber, the shell layer is bisphenol F epoxy resin and bisphenol A epoxy resin, and the curing agent is 3,5-diethyltoluene-2, 4-diamine, the latent curing agent is 2-phenyl-4-methyl-5-hydroxymethylimidazole, the filler is spherical silica, and the particle size of the spherical silica is 0.3 μm. Th...

Embodiment 3

[0048] This embodiment provides a fast-flowing underfill adhesive that can be cured at low temperature, including 20 parts of epoxy resin with core layer-shell layer structure, 20 parts of curing agent, 5 parts of latent curing accelerator, 30 parts of filler, and surfactant 0.01 part, 2 parts of coupling agent, 2 parts of toner, 0.1 part of ion adsorbent, the core layer is high temperature curing amine compound, the shell layer is low temperature curing epoxy compound, the glass transition temperature of high temperature curing amine compound is high The glass transition temperature of epoxy compounds that cure at low temperatures. Specifically, the core layer is amino-modified polymethyl methacrylate-acrylic rubber. The shell layer is bisphenol AD type epoxy resin, bisphenol S type epoxy resin and epoxidized phenol resin, the curing agent is 3,5-diethyltoluene-2,6-diamine, and the latent curing agent is 2 -Phenyl-4,5-Dihydroxymethylimidazole, the filler is spherical silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com