Preparation method of compound bacterium fermentation product for preventing and treating plant phytophthora, compound bacterium fermentation product and application thereof

A technology for fermentation products and compound bacteria, applied in the directions of botanical equipment and methods, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of single strain source, low control effect, single disease prevention mechanism, etc. The effect of the control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of a compound bacterial fermentation product for preventing and treating Phytophthora phytophthora, comprising the following steps: (1) carrying out spore culture of Trichoderma marinum, inoculating the obtained spores into a shaking medium for shaking culture, and obtaining Trichoderma marine shock culture; (2) Bacillus subtilis is carried out seed culture, and the obtained seed culture is inoculated into the shock culture medium for shock culture, and the shock culture of Bacillus subtilis is obtained, and the shock culture of Bacillus subtilis is mixed with The shaking culture of Trichoderma marinum obtained in step (1) is mixed and then co-fermented to obtain a co-fermented product, and the co-fermented product is centrifugally filtered to obtain a composite bacterial fermentation product.

[0033] In the present invention, the marine Trichoderma preferably includes Trichoderma aculeatus or Trichoderma reesei, the Trichoder...

Embodiment 1

[0044] 1. Screening culture of marine Trichoderma

[0045] (1) Trichoderma maritima was statically cultured on potato dextrose agar (PDA) medium at 28°C for 7 days.

[0046] (2) Take the small pieces of mycelia grown from the above culture in 200 mL of nutrient broth (NB) medium, shake and culture at 28° C. and 180 rpm for 15 days to obtain Trichoderma marinum fermentation broth, and set up 3 replicates.

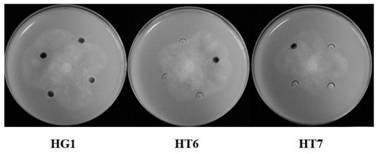

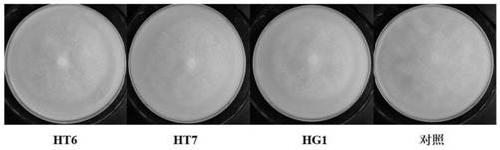

[0047] 2. Marine Trichoderma Activity Assay

[0048] Preparation of marine Trichoderma metabolite solution

[0049] After 15 days, use gauze to separate the culture solution and the bacteria in the Trichoderma marinum fermentation broth, extract the culture solution with 1.5 times the volume of ethyl acetate and concentrate it to dryness, and use a 1:1 mixture of methanol and dichloromethane to extract the culture solution. 100 mL was soaked for 3 days and then filtered. After the filtrate was concentrated, the aqueous phase was extracted with 1.5 times the volume of ethyl...

Embodiment 2

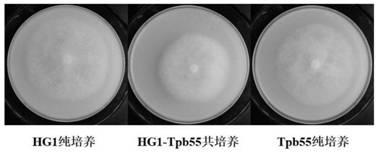

[0059] Construction of an interactive culture system between Trichoderma aculeatus HG1 and Bacillus subtilis Tbp55

[0060] (1) Inoculate HG1 on NA (NB medium plus 20g / L agar) medium, culture at 28°C for 3 days, wash out the spores with sterile water, and make the spore concentration reach 10 5 CFU / mL, then take 1mL into 50mL NB liquid medium, shake and culture at 28°C and 180rpm for 48h, and obtain the shaking culture with mycelium growing;

[0061] (2) Inoculate Tbp55 on NA medium and culture for 24h, then inoculate into 50mL NB medium, culture at 28°C and 180rpm for 24h, and adjust the bacterial concentration to 10 5 CFU / mL, 100 μL was added to the 50 mL shaking culture grown for 48 hours in step (1), and co-fermented at 28° C. and 180 rpm for 6 days to obtain a co-fermentation product of HG1 and Tbp55.

[0062] (3) The co-fermentation product of HG1 and Tbp55 obtained in step (2) was filtered twice with a water membrane to obtain a complex bacterial fermentation product, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com