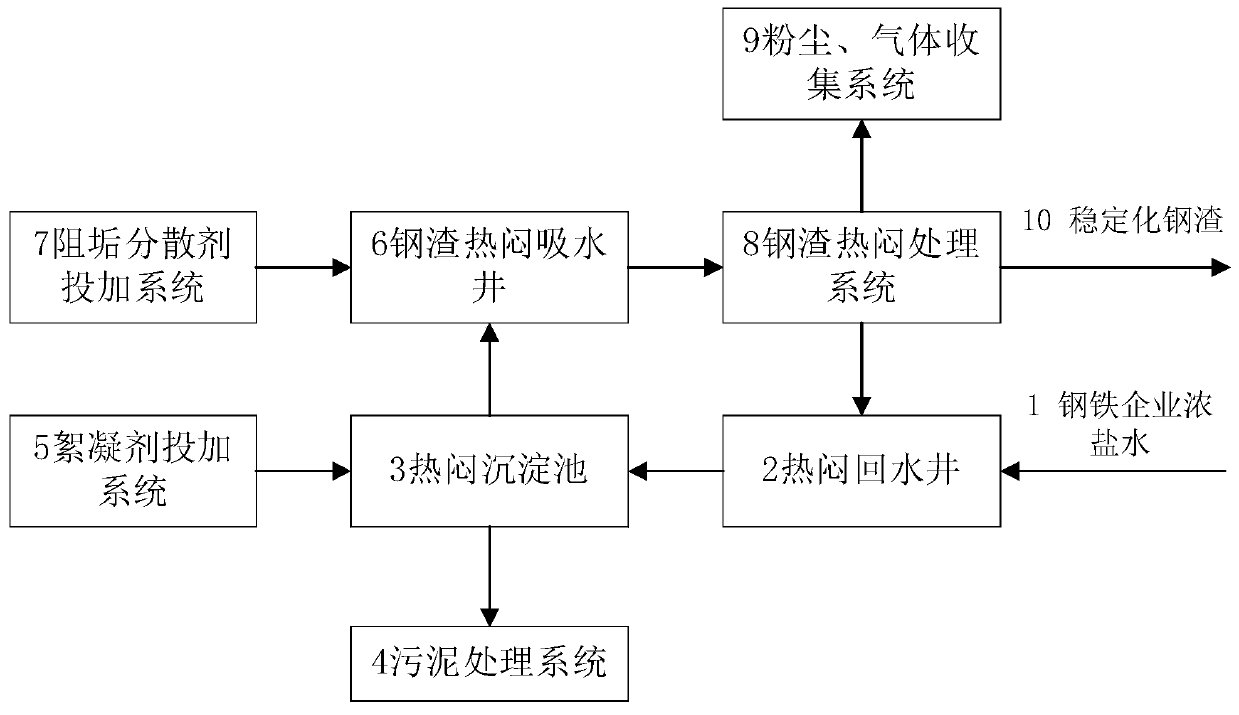

Device for recycling strong brine for steel slag hot-disintegration treatment and treatment method

A treatment method, concentrated brine technology, applied in water/sewage treatment, metallurgical wastewater treatment, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The raw water of an iron and steel enterprise in Hebei was selected as concentrated water after reverse osmosis treatment. After testing, the pH of the concentrated water was 8.41, the total dissolved solids (TDS) was 1430mg / L, and the COD cr 61mg / L, ammonia nitrogen 0.9mg / L, sulfate 510mg / L, chloride ion 328mg / L, total hardness 1083mg / L (calculated as CaCO 3 count).

[0055] Take the concentrated water flow rate as 20m 3 / h is transported to the steel slag hot stuffy backwater well, the water temperature of the steel slag hot stuffy backwater well drops from 90°C to 75°C, the suspended solids (SS) of the backwater well is 458mg / L, and the pH is 11.56.

[0056] The dosing concentration of PAC in the hot stuffy sedimentation tank is 30mg / L, the dosing concentration of PAM is 5mg / L, and the effluent SS of the sedimentation tank is 42mg / L. The concentration of antiscaling and dispersing synergist in hot stuffy suction well is 30mg / L, and the concentration of antiscaling ...

Embodiment 2

[0060] The reverse osmosis concentrated water after the comprehensive sewage treatment of an iron and steel enterprise in Hebei was selected. The pH of the concentrated water was 7.75, the total dissolved solids (TDS) was 3150mg / L, and the COD cr is 119mg / L, ammonia nitrogen is 25mg / L, sulfate is 1260mg / L, chloride ion is 1021mg / L, and total hardness is 1573mg / L (calculated as CaCO 3 count).

[0061] Take the concentrated water flow rate as 20m 3 / h is transported to the steel slag hot stuffy backwater well, the water temperature of the steel slag hot stuffy backwater well drops from 90°C to 75°C, the suspended solids (SS) of the backwater well is 573mg / L, and the pH is 11.35.

[0062] The dosing concentration of PAC in the hot stuffy sedimentation tank is 50mg / L, the dosing concentration of PAM is 5mg / L, and the effluent SS of the sedimentation tank is 35mg / L. The concentration of antiscaling and dispersing synergist in hot stuffy suction well is 50mg / L, and the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com