Film-coated solid acid suitable for deep acid fracturing of carbonate reservoir

A carbonate reservoir and solid acid technology, which is applied in the direction of production fluid, drilling composition, wellbore/well components, etc., can solve the problems of corrosion inhibition and retardation, etc., and achieve corrosion inhibition Good performance, reduced reaction speed, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

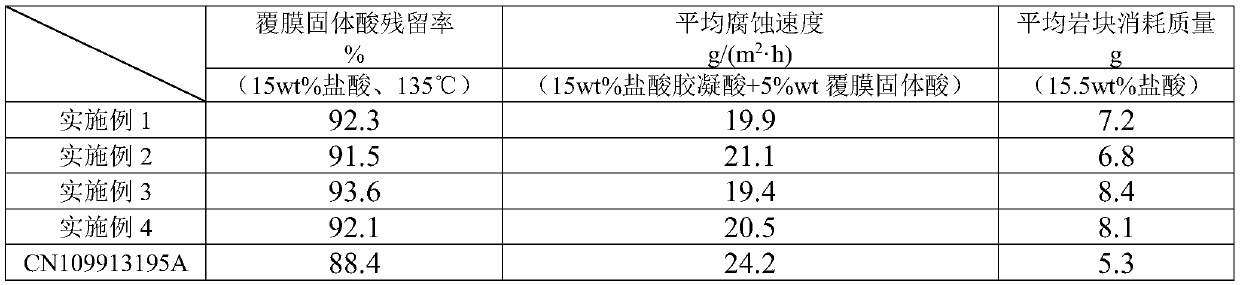

Embodiment 1

[0027] A film-coated solid acid suitable for deep acid fracturing in carbonate reservoirs, the preparation process of which is as follows:

[0028] 1) Add 50g of ethylene oxide, 30g of hydroxyethyl methacrylate, 10g of phthalimide, and 10g of pentaerythritol triallyl ether into an anhydrous and oxygen-free pressure bottle, and continue to add 150g of benzene, 10g of Diethyl zinc, seal, shake well, and let it stand in a 50°C constant temperature water bath for 70 minutes, separate the formed polymer from the liquid, and vacuum dry the polymer to obtain the outer coating material;

[0029] 2) Dissolving 10g of coating material in 70g of absolute ethanol to prepare feed liquid;

[0030] 3) Coating 30 g of feed solution on 20 g of solid hydrochloric acid by spray drying method to prepare coated solid acid.

Embodiment 2

[0032] A film-coated solid acid suitable for deep acid fracturing in carbonate reservoirs, the preparation process of which is as follows:

[0033] 1) Add 45g of ethylene oxide, 25g of hydroxyethyl methacrylate, 15g of phthalimide, and 15g of pentaerythritol triallyl ether into an anhydrous and oxygen-free pressure bottle, and continue to add 150g of benzene, 10g of Diethyl zinc, seal, shake well, and let it stand in a 50°C constant temperature water bath for 70 minutes, separate the formed polymer from the liquid, and vacuum dry the polymer to obtain the outer coating material;

[0034] 2) Dissolving 10g of coating material in 70g of absolute ethanol to prepare feed liquid;

[0035] 3) Coating 30 g of feed solution on 20 g of solid hydrochloric acid by spray drying method to prepare coated solid acid.

Embodiment 3

[0037] A film-coated solid acid suitable for deep acid fracturing in carbonate reservoirs, the preparation process of which is as follows:

[0038] 1) Add 50g of ethylene oxide, 30g of glycidyl methacrylate, 10g of glutarimide, and 10g of trimethylolpropane diallyl ether into an anhydrous and oxygen-free pressure bottle, and continue to add 150g Benzene, 10g of diethylzinc, seal, shake well, and let stand in a constant temperature water bath at 50°C for 70 minutes, separate the formed polymer from the liquid, and vacuum dry the polymer to obtain the outer coating material;

[0039] 2) Dissolving 10g of coating material in 70g of absolute ethanol to prepare feed liquid;

[0040] 3) Coating 30 g of feed solution on 20 g of solid hydrochloric acid by spray drying method to prepare coated solid acid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com