Novel three-dimensional silicon structure supercapacitor electrode material and preparation method thereof

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of high manufacturing cost, complex preparation steps, and complicated processes, and achieve process compatibility, cost reduction, low cost, etc. The effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

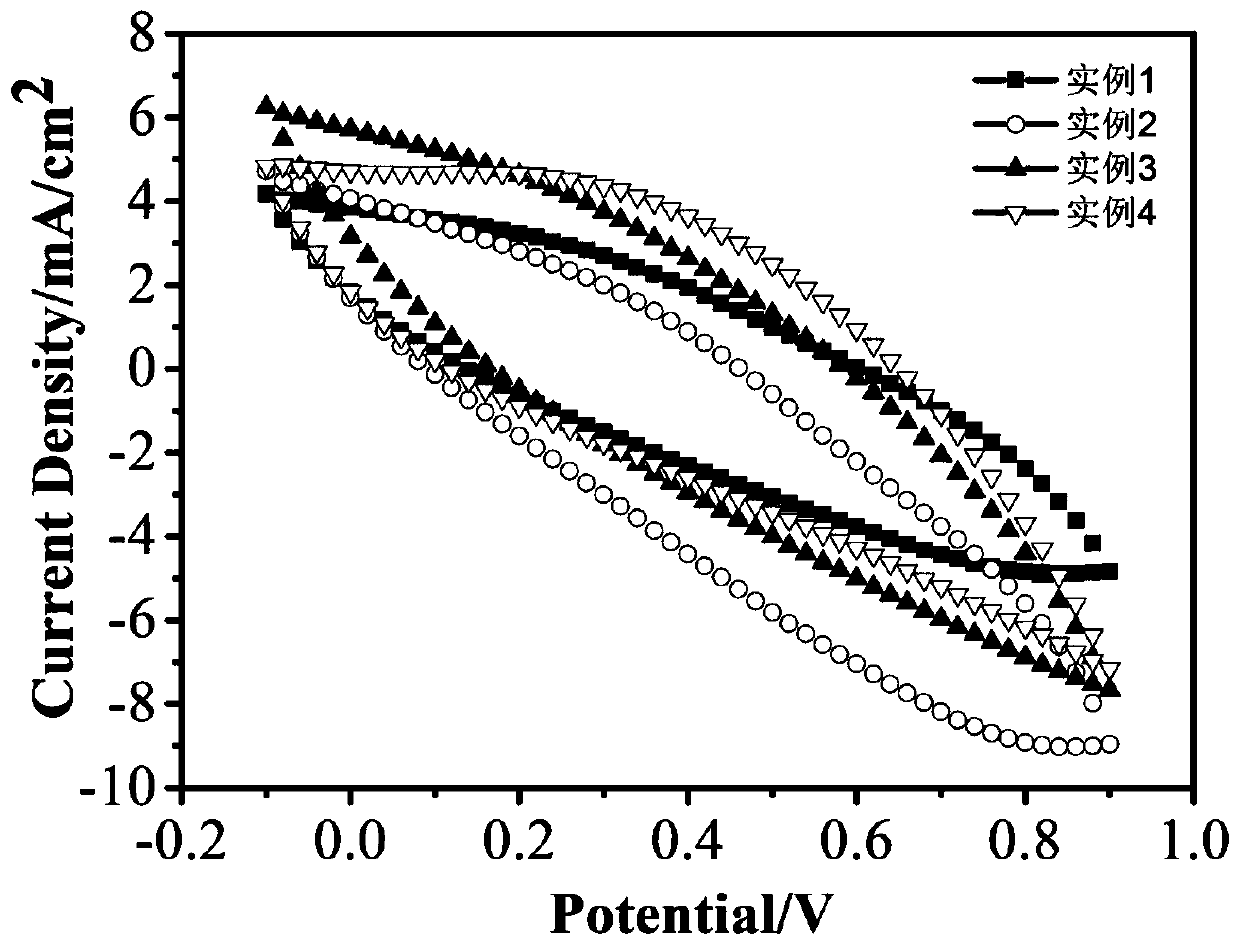

Embodiment 1

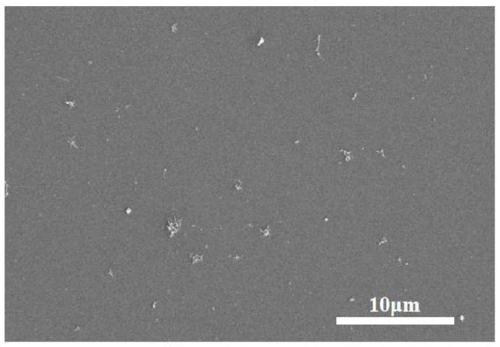

[0029] (1) Silicon nanowires (SiNWs) were prepared by solution etching, and treated twice to prepare a silicon substrate with a three-dimensional surface structure.

[0030] (a) Select N-type (100 crystal orientation), single-sided polished silicon wafer with a resistivity of 5-7Ω cm, cut into 1cm*2cm samples, wash with ethanol and deionized water for many times; Put it into the etching solution containing 5mol / L and 0.02mol / L silver nitrate and etch for 60min.

[0031] (b) Soak the silicon wafer in a concentrated nitric acid solution for more than 1 hour to remove the residual silver particles on the surface of the silicon nanowires, then fully wash it with deionized water, and dry it at a high speed with a homogenizer.

[0032] (c) The silicon wafer is immersed in a chlorobenzene saturated solution of phosphorus pentachloride for secondary treatment. The treatment time is 3 hours, and the treatment temperature is 120° C.

[0033] (2) Spin-coat 3 layers of PEDOT:PSS solution...

Embodiment 2

[0037] (1) Silicon nanowires (SiNWs) were prepared by solution etching, and treated twice to prepare a silicon substrate with a three-dimensional surface structure.

[0038] (a) Select N-type (100 crystal orientation), single-sided polished silicon wafer with a resistivity of 5-7Ω cm, cut into 1cm*2cm samples, wash with ethanol and deionized water for many times; Put it into the etching solution containing 5mol / L and 0.02mol / L silver nitrate and etch for 60min.

[0039] (b) Soak the silicon wafer in a concentrated nitric acid solution for more than 1 hour to remove the residual silver particles on the surface of the silicon nanowires, then fully wash it with deionized water, and dry it at a high speed with a homogenizer.

[0040] (c) The silicon wafer is immersed in a chlorobenzene saturated solution of phosphorus pentachloride for secondary treatment. The treatment time is 3 hours, and the treatment temperature is 120° C.

[0041] (2) Spin-coat 3 layers of PEDOT:PSS solution...

Embodiment 3

[0047] (1) Silicon nanowires (SiNWs) were prepared by solution etching, and treated twice to prepare a silicon substrate with a three-dimensional surface structure.

[0048] (a) N-type (100 crystal orientation), single-sided polished silicon wafer with a resistivity of 5-7Ω·cm, cut into 1cm*2cm samples, washed with ethanol and deionized water for many times; at room temperature and pressure Put it into the etching solution containing 5mol / L and 0.02mol / L silver nitrate and etch for 60min.

[0049] (b) Soak the silicon wafer in a concentrated nitric acid solution for more than 1 hour to remove the residual silver particles on the surface of the silicon nanowires, then fully wash it with deionized water, and dry it at a high speed with a homogenizer.

[0050] (c) The silicon wafer is immersed in a chlorobenzene saturated solution of phosphorus pentachloride for secondary treatment. The treatment time is 3 hours, and the treatment temperature is 120° C.

[0051] (2) Spin-coat 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com