Catalyst for co-production of methyl acetate and acetone from dimethyl ether and preparation method and application thereof

A methyl acetate and catalyst technology, applied in the field of heterogeneous catalysis, can solve the problems of long process flow, dependence on petroleum resources, strong corrosion, etc., and achieve the effects of simple process, guaranteed flexibility, and strong industrial application background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

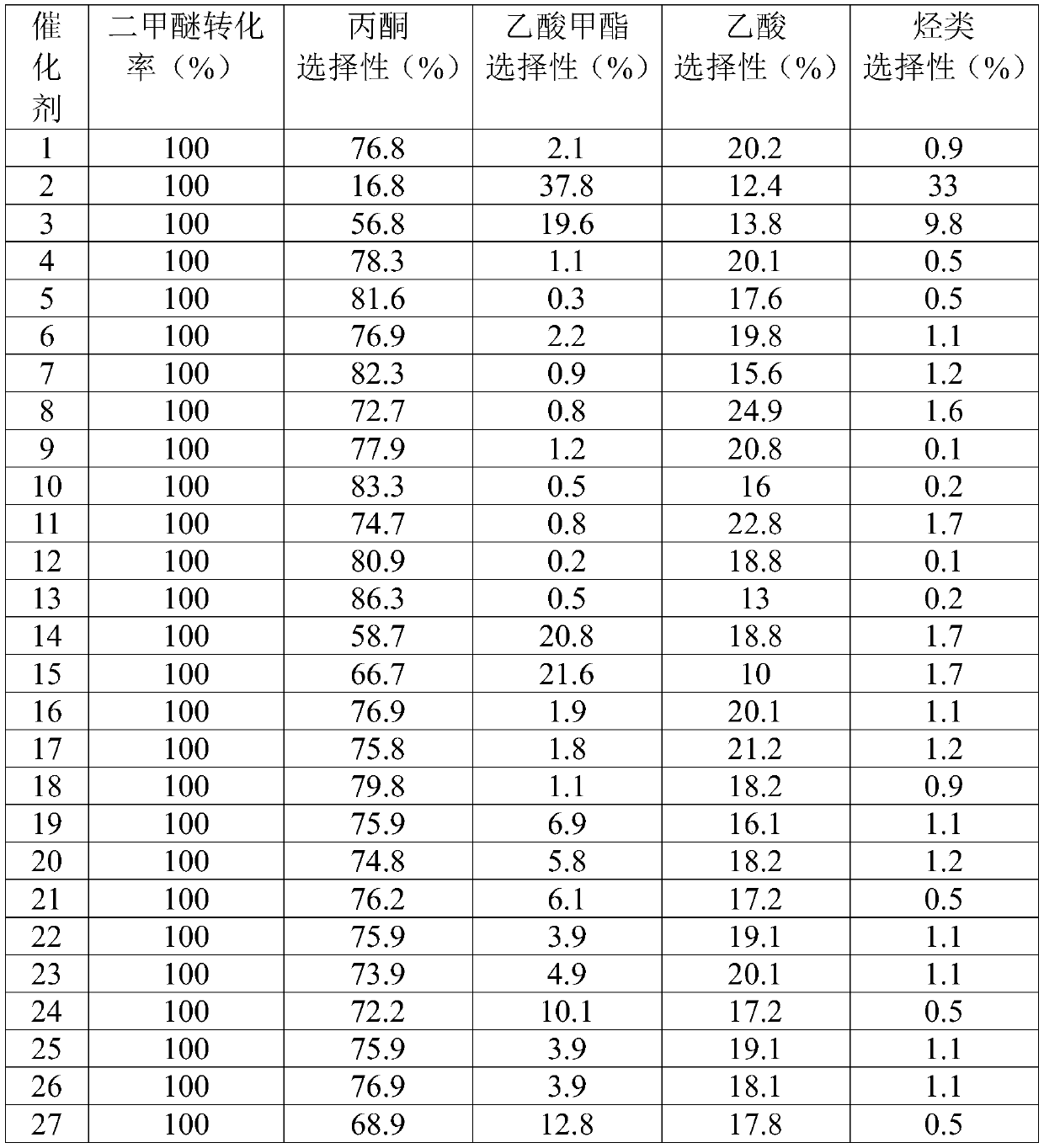

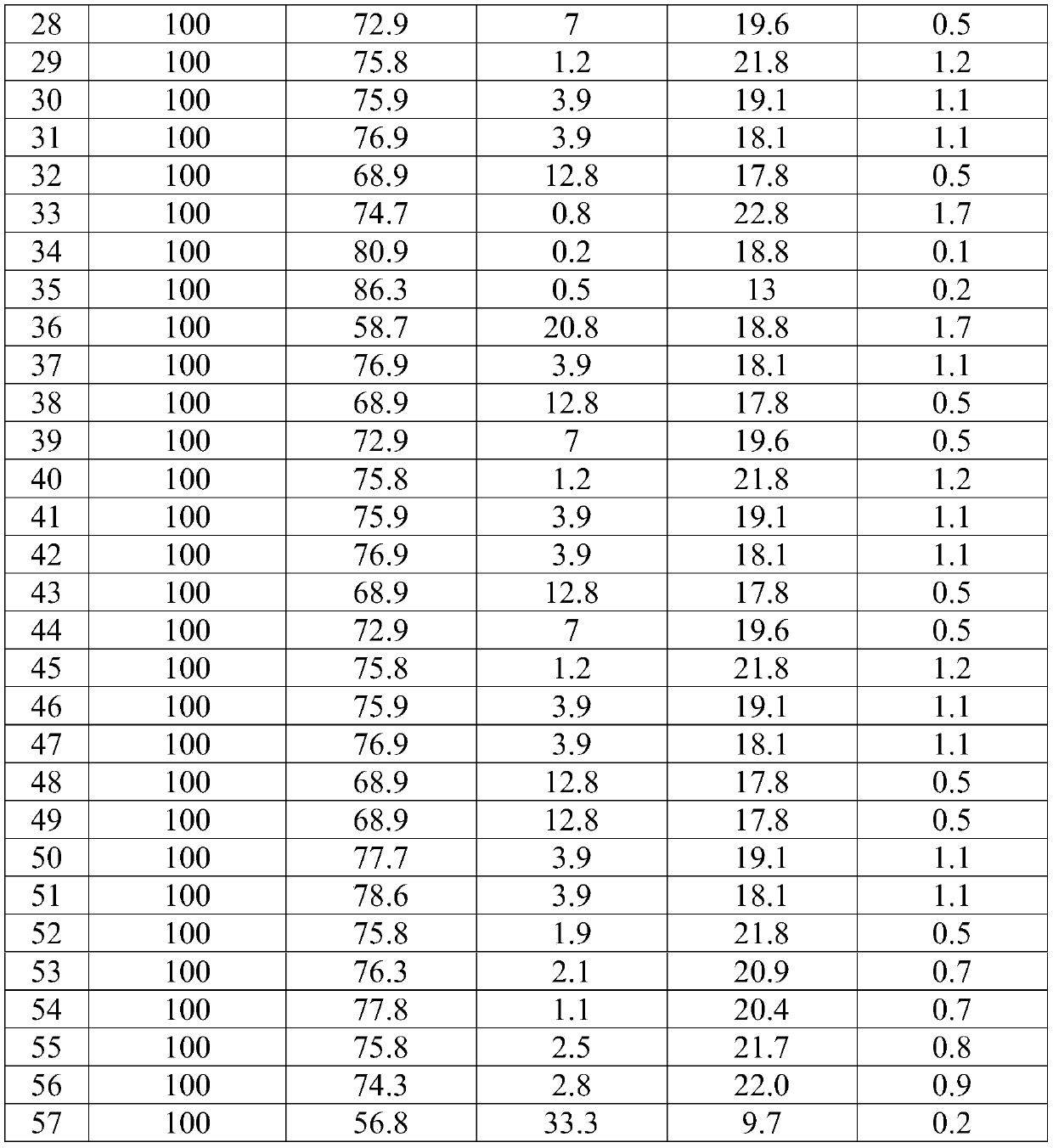

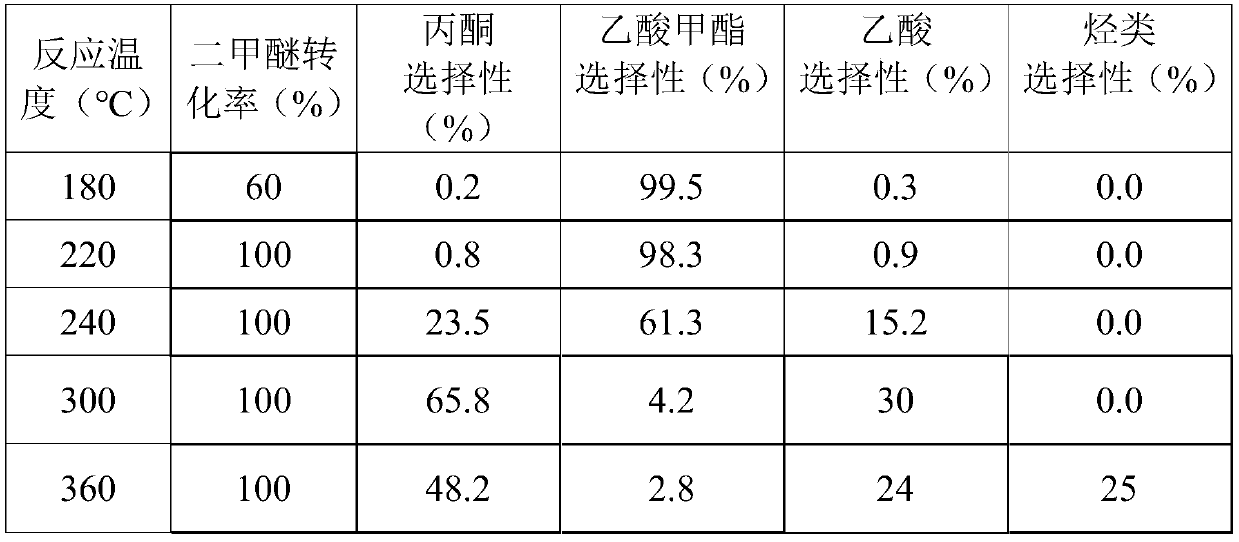

Examples

Embodiment 1

[0046] Put 100 grams of MOR (Si / Al=15) molecular sieves into 1000 ml of 0.5 mol / L NaOH solution at 80° C. for 2 hours, filter and wash until neutral. Take out the MOR after alkali treatment of 80g, mix 28g pseudo-boehmite with 10% dilute nitric acid and extrude into strips, after roasting, exchange with 0.5mol / L ammonium nitrate three times (2 hours / time), wash with deionized water , dried, and calcined at 550°C for 4 hours, and the obtained sample was treated at 300°C in an atmosphere containing pyridine for 2 hours to obtain Catalyst 1.

Embodiment 2

[0048] 100 grams of MOR (Si / Al respectively 6.8, 10.5, 20, 30) molecular sieves were placed in 1000 ml of NaOH solution with a concentration of 0.5 mol / L and treated at 80 ° C for 2 hours, filtered and washed until neutral. Take out the MOR after alkali treatment of 80g, mix 28g pseudo-boehmite with 10% dilute nitric acid and extrude into strips, after roasting, exchange with 0.5mol / L ammonium nitrate three times (2 hours / time), wash with deionized water , dried, and calcined at 550°C for 4 hours, and the obtained samples were treated at 300°C in an atmosphere containing pyridine for 2 hours to obtain catalysts 2, 3, 4, and 5.

Embodiment 3

[0050] The content of iron in the MOR catalyst is 0.01wt%, 1.8wt%, 5wt%; the content of gallium is 0.01wt%, 1.8wt%, 5wt%; the content of iron (gallium) is 0.01wt% (0.03wt%), 3wt% (0.5wt%), and the other conditions were consistent with Example 1 to prepare catalysts 6, 7, 8, 9, 10, 11, 12, and 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com