Method for rapidly detecting free toluene diisocynate in polyurethane coating

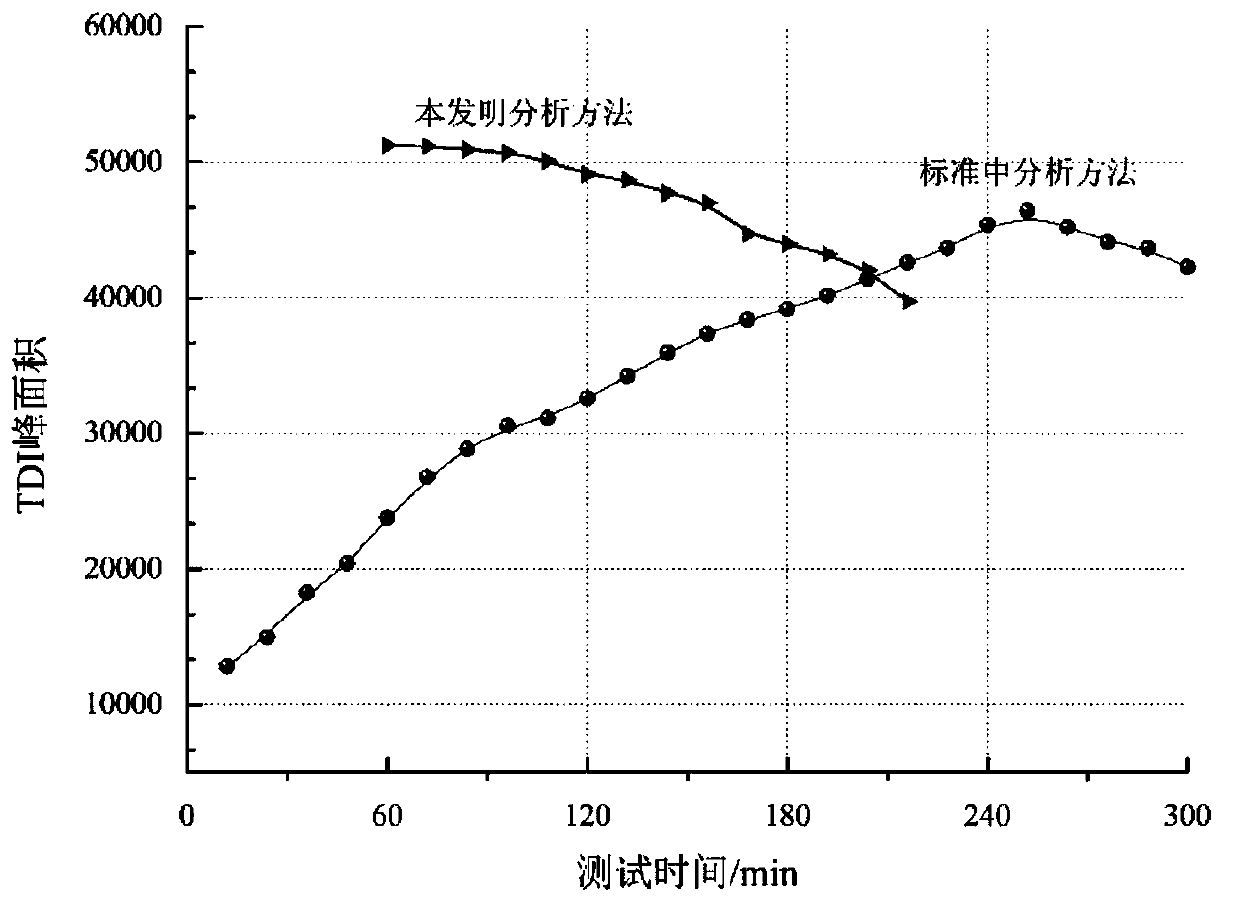

A toluene diisocyanate and polyurethane coating technology, applied in the field of chromatographic analysis, can solve the problems of high detection results, influence of detection results, difficulty in timeliness and accuracy of detection data, etc., and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

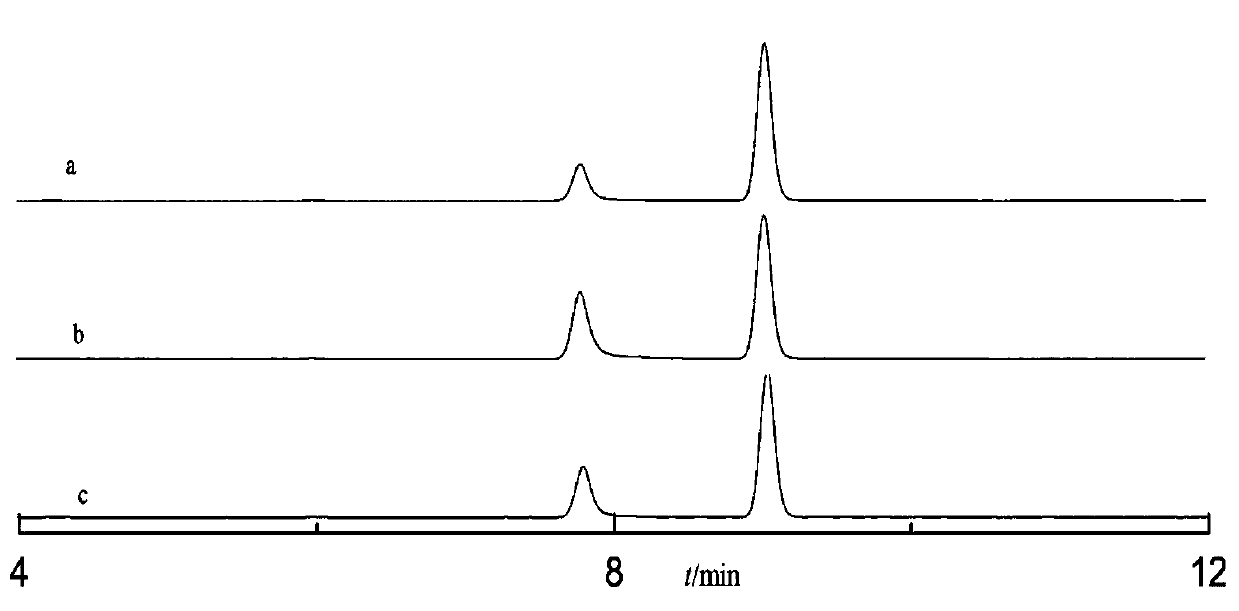

[0039] This example provides a rapid detection method for free toluene diisocyanate in polyurethane coatings (model S I N B in GB / T 19250-2013 "Polyurethane Waterproof Coatings", purchased from Keshun Waterproof Technology Co., Ltd.), the detection method adopts gas chromatography Method is carried out, wherein, described gas chromatography comprises the steps:

[0040] (1) Preparation of 3% toluene diisocyanate solution: Weigh 0.3056 g of toluene diisocyanate into a 10 mL sample bottle, then quickly add 10 g of dehydrated ethyl acetate and seal it.

[0041] (2) Adopt Shimadzu GC-2014C gas chromatograph to analyze above-mentioned preparation solution immediately; GC is equipped with hydrogen flame ionization detector (FID) and AOC-20i autosampler, and the working condition of gas chromatograph is as follows:

[0042] Chromatographic column: HP-5, the specification is 30m×0.25mm×0.25μm;

[0043] Inlet temperature: 145°C;

[0044] FID detector temperature: 250°C;

[0045] Pro...

Embodiment 2

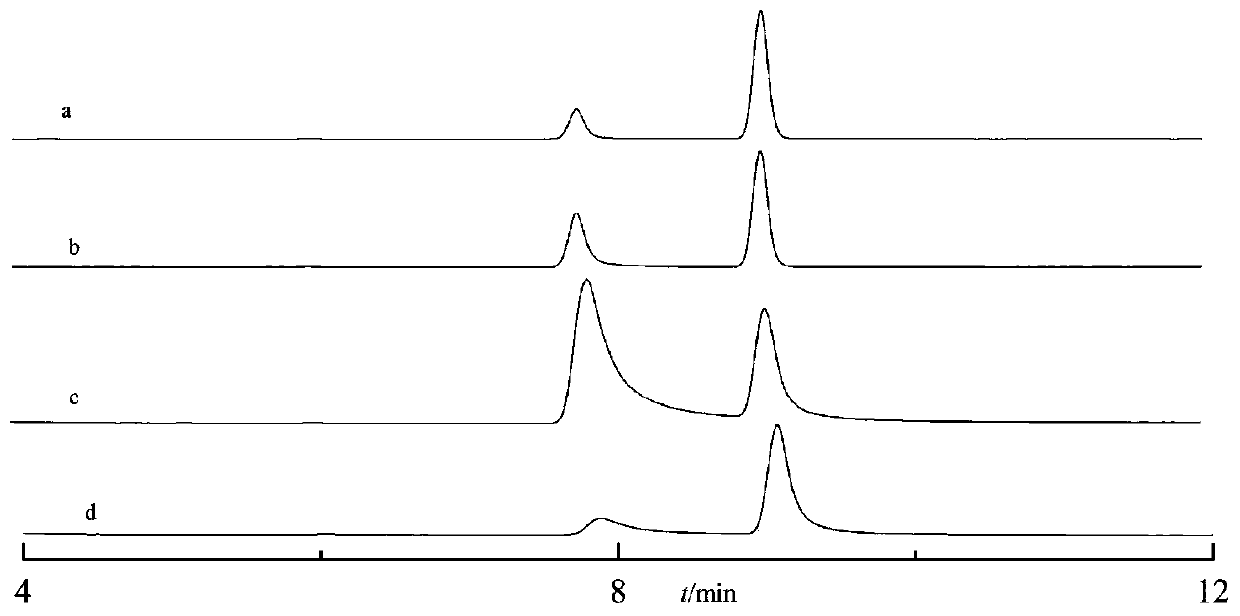

[0070] This example provides a rapid detection method for free toluene diisocyanate in polyurethane coatings. The detection method is carried out by gas chromatography, wherein: the configuration, analysis method, and result calculation of the calibration solution in Example 2 are completely consistent with Example 1. The only difference is that the type of polyurethane coating is adjusted, specifically a two-component polyurethane coating (model M I N B in GB / T19250-2013 "Polyurethane Waterproof Coating", purchased from Jiangsu Hongyuan Zhongfu Waterproof Material Co., Ltd.). The calibration factor calculation of the calibration solution is shown in Table 1, the free TDI content results in the sample are shown in Table 3, and the gas chromatographic analysis spectrum is shown in Table 1. figure 2 shown.

[0071] Free TDI content in the sample of table 3

[0072]

[0073] It can be seen from Table 3 that the free TDI content in the sample is estimated to be about 21g / kg, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com