A conductive stable negative Poisson's ratio structure myocardial patch and its preparation method

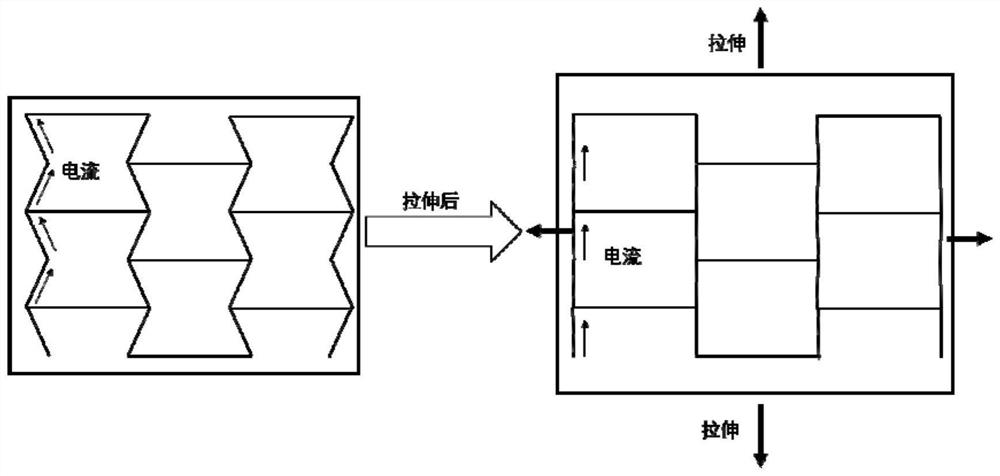

A technology with negative Poisson's ratio and stability, which is applied in the field of biomedical materials, can solve the problems of myocardial patches that are difficult to match electrical and mechanical behaviors, and difficult to maintain electrical conductivity, so as to achieve excellent mechanical properties, stable electrical conductivity, and meet the requirements of stretching. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] A preparation method of a negative Poisson's ratio structure myocardial patch with conductive stability, comprising the following steps:

[0116] (1) adding a certain mass fraction of pyrrole monomer into ferric chloride solution and stirring for 4h, then filtering, washing and drying to obtain polypyrrole particles (the molar ratio of ferric chloride to pyrrole monomer is 2.3:1);

[0117] (2) adding polypyrrole particles to 30wt% polyurethane solution and stirring evenly to obtain a solution (30wt% of polypyrrole particles in the solution);

[0118] (3) immerse the polyurethane yarn and the polylactic acid yarn in the above solution for 5 minutes, fully absorb;

[0119] (4) After washing polypyrrole-coated polyurethane yarn and polypyrrole-coated polylactic acid yarn with deionized water for 2 times, dry at room temperature to obtain conductive polypyrrole-coated polyurethane yarn and polypyrrole-coated polylactic acid yarn;

[0120] (5) Using conductive polypyrrole-c...

Embodiment 2

[0125] A preparation method of a negative Poisson's ratio structure myocardial patch with conductive stability, comprising the following steps:

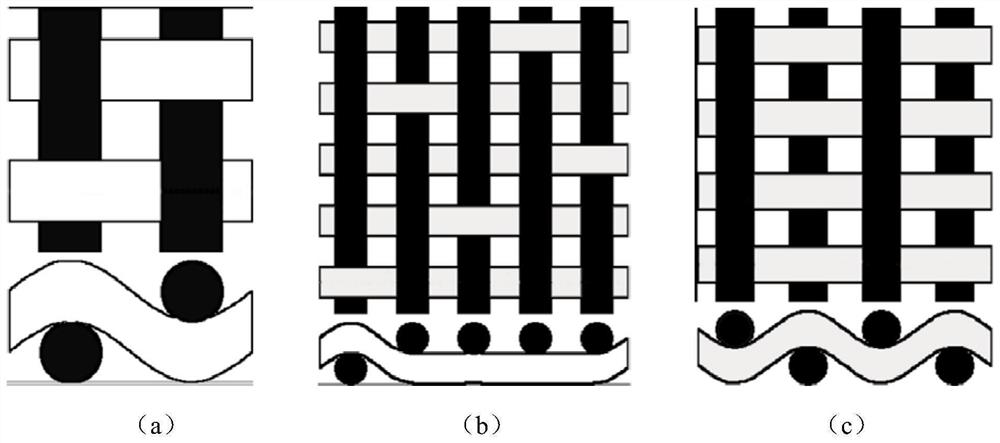

[0126] (1) Polycaprolactone yarn is selected as elastic yarn, polylactic acid yarn is used as non-elastic yarn, double-needle plate latch weft knitting machine is adopted, and the number of non-elastic yarn and elastic yarn is 2:1 alternately arrangement;

[0127] (2) Knitting needles according to Figure 4 The weaving pattern shown is regularly looped to form a concave hexagonal pattern;

[0128] (3) Before the fabric is off the machine, coat the fabric 3 times with a polyurethane solution containing sodium dodecylbenzenesulfonate and ammonium persulfate; wherein, in the polyurethane solution, the content of sodium dodecylbenzenesulfonate is 1 % w / v, the content of ammonium persulfate is 3% w / v, the content of polyurethane is 10% w / v;

[0129] (4) Fumigate the coated fabric with pyrrole monomer (excess) at 4°C for 12 hours;

[0...

Embodiment 3

[0134] A preparation method of a negative Poisson's ratio structure myocardial patch with conductive stability, comprising the following steps:

[0135] (1) Select polycaprolactone yarn as elastic yarn raw material, polylactic acid as non-elastic yarn, and adopt a rapier loom with multiple weft yarn supply and dobby shedding mechanism;

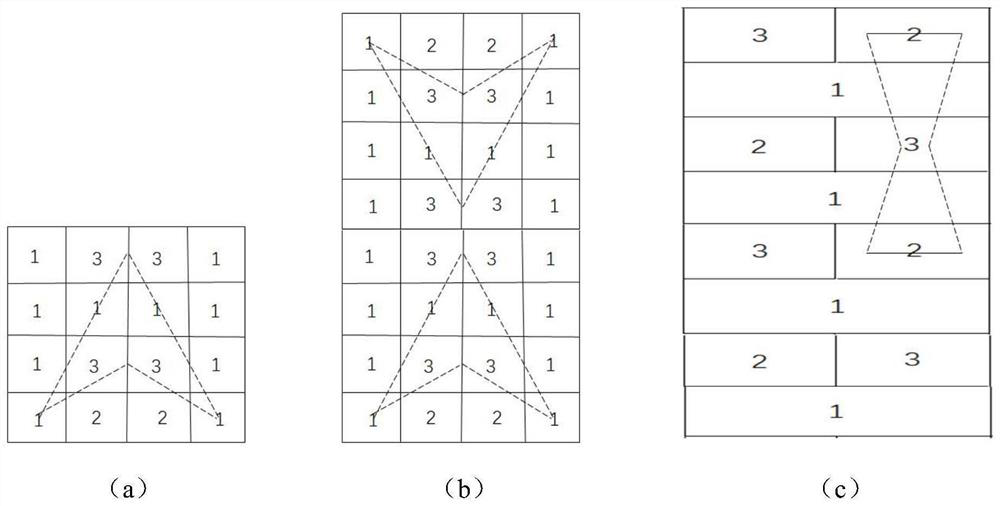

[0136] (2) Winding, warping, sizing, and reeding warp yarns (polycaprolactone yarns and polylactic acid yarns alternately prepared at a ratio of 1:1), and weft yarns are made of polycaprolactone yarns. figure 2 (a) shows the schematic diagram, image 3 As shown in the tissue diagram, opening, weft insertion, beating up, and coiling are performed to obtain the base material of the myocardial patch; wherein, tissue 1 ( image 3 In (a)) is plain weave, weave 2 ( image 3 (b)) is twill weave, and weave 3 ( image 3 (c)) is a structure in which the warp yarns alternately float on the weft yarns, and the structure density of structures 1, 2 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com