Preparation method of bismuth tungstate nitrogen and sulfur co-modified biochar

A technology of biochar and bismuth tungstate, applied in chemical instruments and methods, catalyst activation/preparation, chemical/physical processes, etc., can solve problems such as poor photocatalytic activity and easy recombination of photogenerated electrons and holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

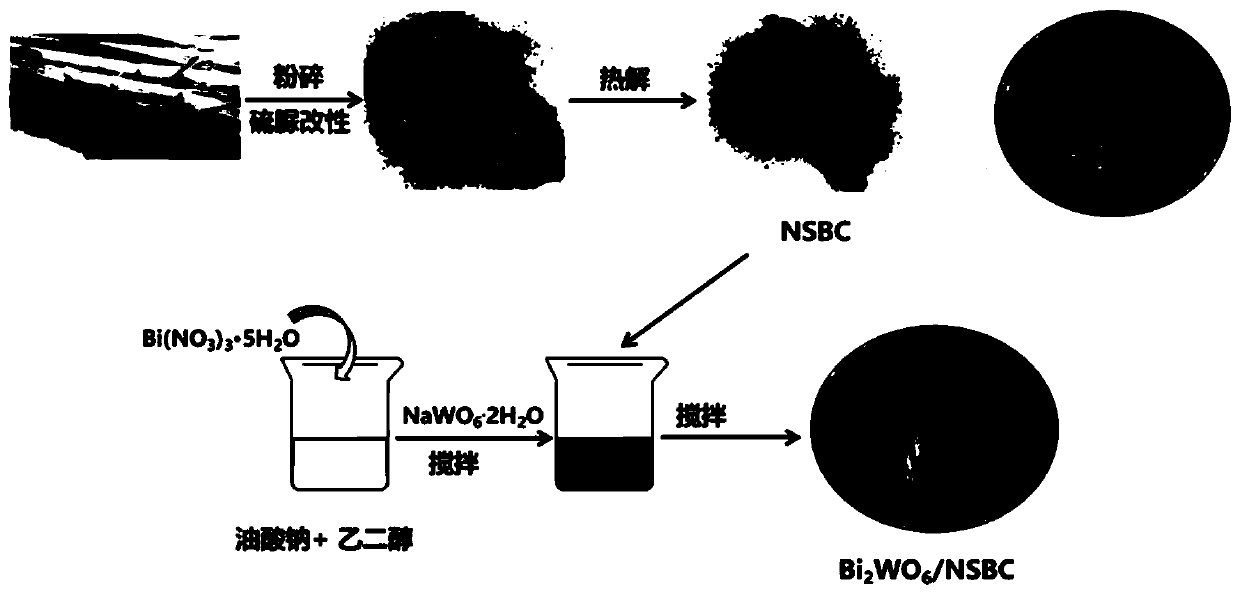

[0035] The embodiment of the present invention provides a preparation method of bismuth tungstate nitrogen and sulfur co-modified biochar, which includes the following steps:

[0036] S1. The biochar raw material is infiltrated and modified with thiourea, and the modified material is placed in nitrogen to react to obtain nitrogen and sulfur doped modified biochar NSBC;

[0037] S2, using ethylene glycol as a solvent to prepare a mixed solution of sodium oleate and bismuth nitrate pentahydrate;

[0038] S3. Add sodium tungstate dihydrate to the mixed solution of sodium oleate and bismuth nitrate;

[0039] S4, adding the nitrogen-sulfur-doped modified biochar NSBC obtained in step S1 to the mixed solution obtained in step S3;

[0040] S5, reacting the mixed solution obtained in step S4;

[0041] S6. Obtain the reactant solid obtained after the reaction in step S5;

[0042] S7. Dry the reactant solid to obtain bismuth tungstate nitrogen and sulfur co-modified biochar Bi 2 WO 6 / NSBC.

[0043]...

Embodiment 1

[0055] Collect fresh corn stalks, clean the surface silt with distilled water, then dry, pulverize with a grinder, pass through a 60-mesh sieve, drop two drops of dilute nitric acid for 20h, dry in an oven at 80℃, take 8g Thiourea was dissolved in 50mL of distilled water, added 4g of dried corn stalks and fully stirred for 1 hour, dried at 80℃, and the modified material was placed in a porcelain crucible, in a vacuum muffle furnace with nitrogen gas for 600 Reaction at ℃ for 3h, after cooling, NSBC-1 was obtained; meanwhile, 4mmol of sodium oleate was dissolved in 40mL of ethylene glycol, and 4mmol of bismuth nitrate pentahydrate was added when sodium oleate was completely dissolved; 2mmol of sodium tungstate dihydrate was heated at 60℃ Dissolve it in 20mL ethylene glycol, and add it to the mixed solution of sodium oleate and bismuth nitrate after it is completely dissolved and stir for 30 minutes; take 0.05g of NSBC-1 prepared in the first step and dissolve it in 10mL ethylene ...

Embodiment 2

[0058] Collect fresh corn stalks, clean the surface sediment with distilled water, then dry, pulverize it with a pulverizer, pass through a 60-mesh sieve, drop two drops of dilute nitric acid for 20h, dry in an oven at 80℃, take 6g Thiourea was dissolved in 50mL of distilled water, added 4g of dried corn stalks and fully stirred for 1 hour, dried at 80℃, and the modified material was placed in a porcelain crucible, in a vacuum muffle furnace with nitrogen gas for 600 Reaction at ℃ for 3h, after cooling, NSBC-2 was obtained; at the same time, 4mmol of sodium oleate was dissolved in 40mL of ethylene glycol, and 4mmol of bismuth nitrate pentahydrate was added when sodium oleate was completely dissolved; 2mmol of sodium tungstate dihydrate was heated at 60℃ Dissolve it in 20mL ethylene glycol under the condition, add sodium oleate and bismuth nitrate mixed solution after it is completely dissolved and stir for 30min; take 0.05g of NSBC-2 prepared in the first step and dissolve it in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com