Industrial circulating water integral treatment system and process

A technology of industrial circulating water and treatment system, applied in natural water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of long and complicated process route, large investment, etc., to improve solubility, increase solubility, and improve solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

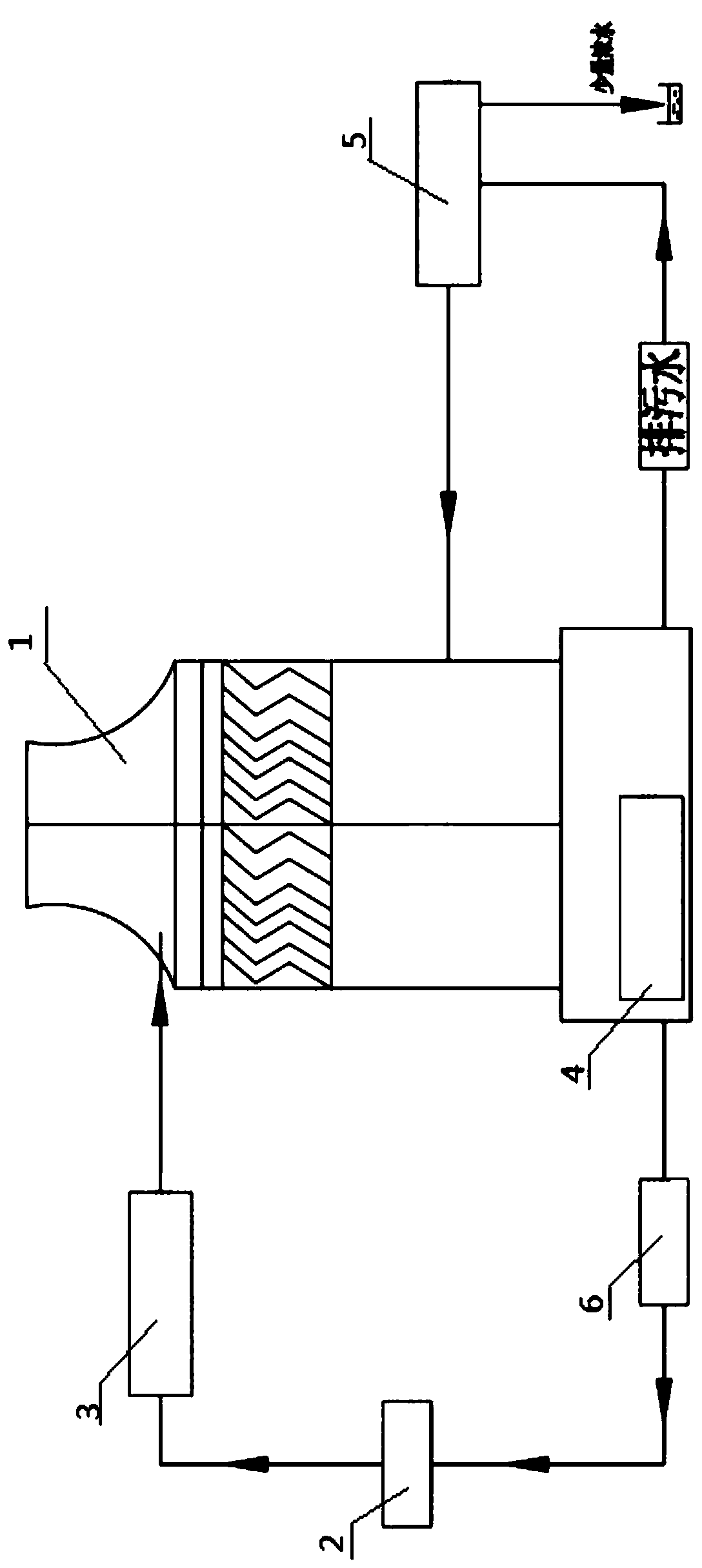

[0037]Turn on the circulation pump and start it, and under the action of the circulation pump, the cooling water in the circulating water cooling tower is introduced into the heat exchanger to cool down the production materials, and the heated cooling water returns to the circulating water cooling tower for cooling , forming the first cycle, the first electrochemical treatment system is installed on the pipeline between the heat exchanger and the circulating water cooling tower, and the heated cooling water flows through the first electrochemical treatment system during the return process, and the first electrochemical treatment system The chemical treatment system adopts an electrochemical coupling ultra-low frequency wave device, and it is a pipeline-type electrochemical container. An external electric field is set in the first electrochemical treatment system to control the frequency and wavelength in the pipeline-type electrochemical container. The frequency is controlled at...

Embodiment 2

[0042] Turn on the circulation pump and start it, and under the action of the circulation pump, the cooling water in the circulating water cooling tower is introduced into the heat exchanger to cool down the production materials, and the heated cooling water returns to the circulating water cooling tower for cooling , forming the first cycle, the first electrochemical treatment system is installed on the pipeline between the heat exchanger and the circulating water cooling tower, and the heated cooling water flows through the first electrochemical treatment system during the return process, and the first electrochemical treatment system The chemical treatment system adopts an electrochemical coupling ultra-low frequency wave device, and it is a pipeline-type electrochemical container. An external electric field is set in the first electrochemical treatment system to control the frequency and wavelength in the pipeline-type electrochemical container. The frequency is controlled a...

Embodiment 3

[0047] Turn on the circulation pump and start it, and under the action of the circulation pump, the cooling water in the circulating water cooling tower is introduced into the heat exchanger to cool down the production materials, and the heated cooling water returns to the circulating water cooling tower for cooling , forming the first cycle, the first electrochemical treatment system is installed on the pipeline between the heat exchanger and the circulating water cooling tower, and the heated cooling water flows through the first electrochemical treatment system during the return process, and the first electrochemical treatment system The chemical treatment system adopts an electrochemically coupled ultra-low frequency wave device, and it is a pipeline-type electrochemical container. An external electric field is set in the first electrochemical treatment system to control the frequency and wavelength in the pipeline-type electrochemical container, and the frequency is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com