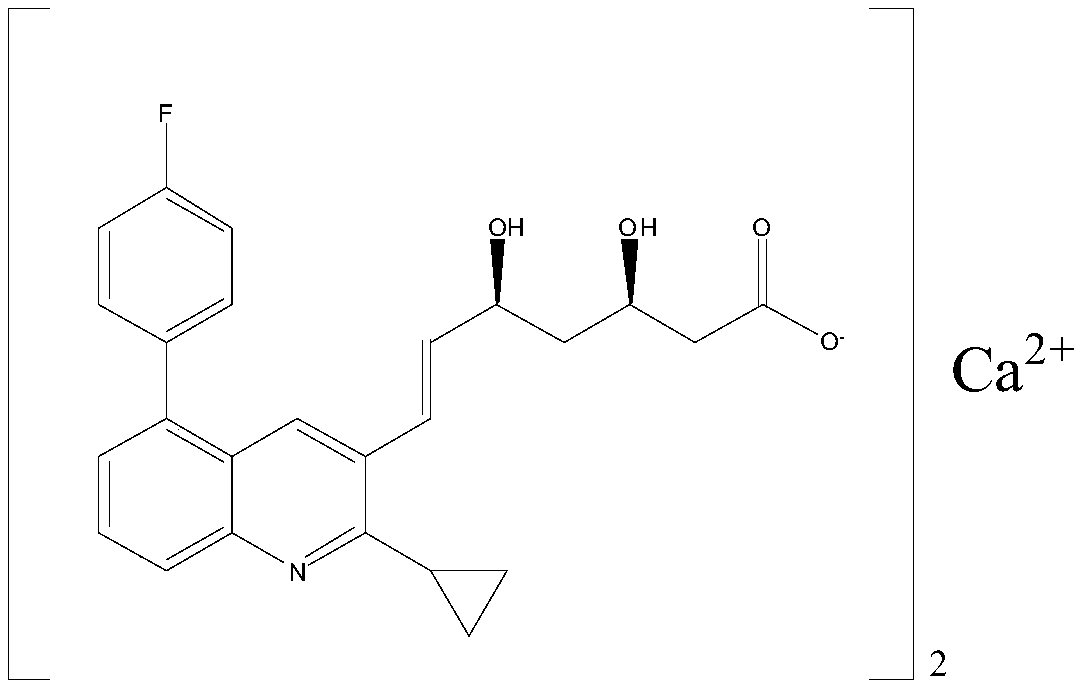

Method for synthesizing pitavastatin calcium intermediate by micro-channel reactor

A microchannel reactor, pitavastatin calcium technology, applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, chemical/physical/physical-chemical processes, etc., can solve the intermediate yield of pitavastatin calcium Low cost, high protection requirements for production operators, and high cost of L-camphorsulfonic acid, achieving the effect of saving production time, cost, production control of three wastes, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

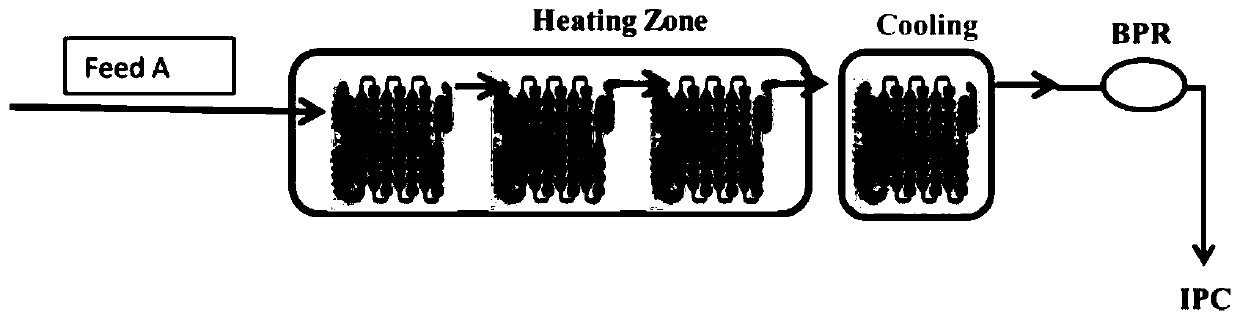

[0049] Embodiment 1: The method utilizing microchannel reactor to synthesize pitavastatin calcium

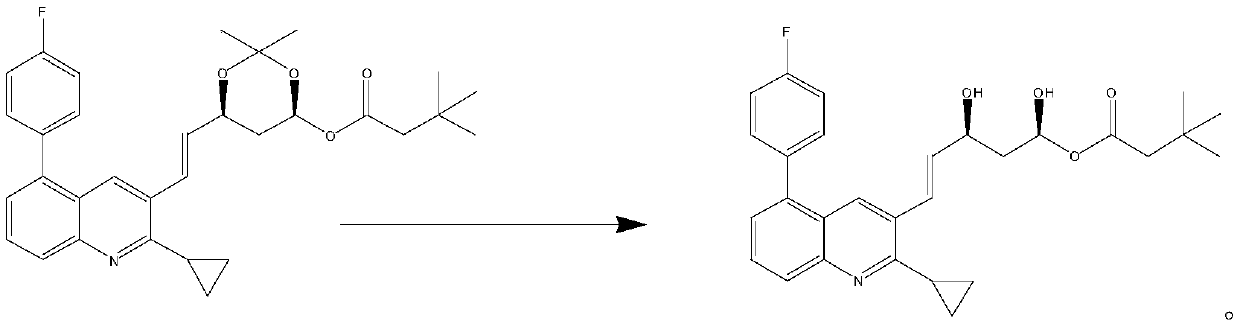

[0050] Take by weighing 5g hydroxylamine hydrochloride (0.07mol), be dissolved in the mixed solution of methanol, acetone and purified water, wherein the amount of methanol is 50ml, the amount of acetone is 40ml, the amount of purified water is 18ml, then weigh 10g of 7- [2-Cyclopropyl-4-(4-fluorophenyl)-3-quinolin-yl]-3,5-dihydroxy-6-heptanoic acid ethyl ester (molecular weight: 517.637, 0.0193mol) was dissolved in the above mixture Then filter the reaction precursor solution to remove mechanical impurities to obtain the mixed solution before sample injection, then pump the mixed solution into the preheating module through the infusion pump for preheating, and then enter the reaction module group for reaction, adjust the flow rate to 25ml / min, after the reaction, the reaction solution enters the cooling module to cool down and then flows out. The reaction temperature is 100°C...

Embodiment 2

[0051] Embodiment 2: The method utilizing microchannel reactor to synthesize pitavastatin calcium

[0052] Take by weighing 5g hydroxylamine hydrochloride (0.07mol), be dissolved in the mixed solution of ethanol, acetone and purified water, wherein the amount of ethanol is 50ml, the amount of acetone is 40ml, the amount of purified water is 18ml, then weigh 10g of 7- [2-Cyclopropyl-4-(4-fluorophenyl)-3-quinolin-yl]-3,5-dihydroxy-6-heptanoic acid ethyl ester (molecular weight: 517.637, 0.0193mol) was dissolved in the above mixture Then filter the reaction precursor solution to remove mechanical impurities to obtain the mixed solution before sample injection, then pump the mixed solution into the preheating module through the infusion pump for preheating, and then enter the reaction module group for reaction, adjust the flow rate to 25ml / min, after the reaction, the reaction solution enters the cooling module to cool down and then flows out. The reaction temperature is 100°C, ...

Embodiment 3

[0053] Embodiment 3: the method utilizing microchannel reactor to synthesize pitavastatin calcium

[0054] Take by weighing 2.5g hydroxylamine hydrochloride (0.035mol), be dissolved in the mixed solution of isopropanol, acetone and purified water, wherein the amount of isopropanol is 50ml, the amount of acetone is 40ml, the amount of purified water is 18ml, then weigh Take 10g of 7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolin-yl]-3,5-dihydroxy-6-heptanoic acid ethyl ester (molecular weight: 517.637, 0.0193mol) In the above mixed solution, filter the solution of the reaction precursor to remove mechanical impurities to obtain the mixed solution before sampling, then pump the mixed solution into the preheating module through the infusion pump for preheating, and then enter the reaction module group for reaction, adjust the flow rate It is 15ml / min. After the reaction, the reaction solution enters the cooling module to cool down and then flows out. The reaction temperature is 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com