Method for preparing flexible two-dimensional polyaniline film by utilizing gas diffusion

A technology of polyaniline film and gas diffusion, which is applied in the direction of instruments, analytical materials, measuring devices, etc., can solve the problems of slow response-recovery time, cumbersome follow-up processing, and low detection limit, and achieve uniform appearance, low cost, and post-processing Handle simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

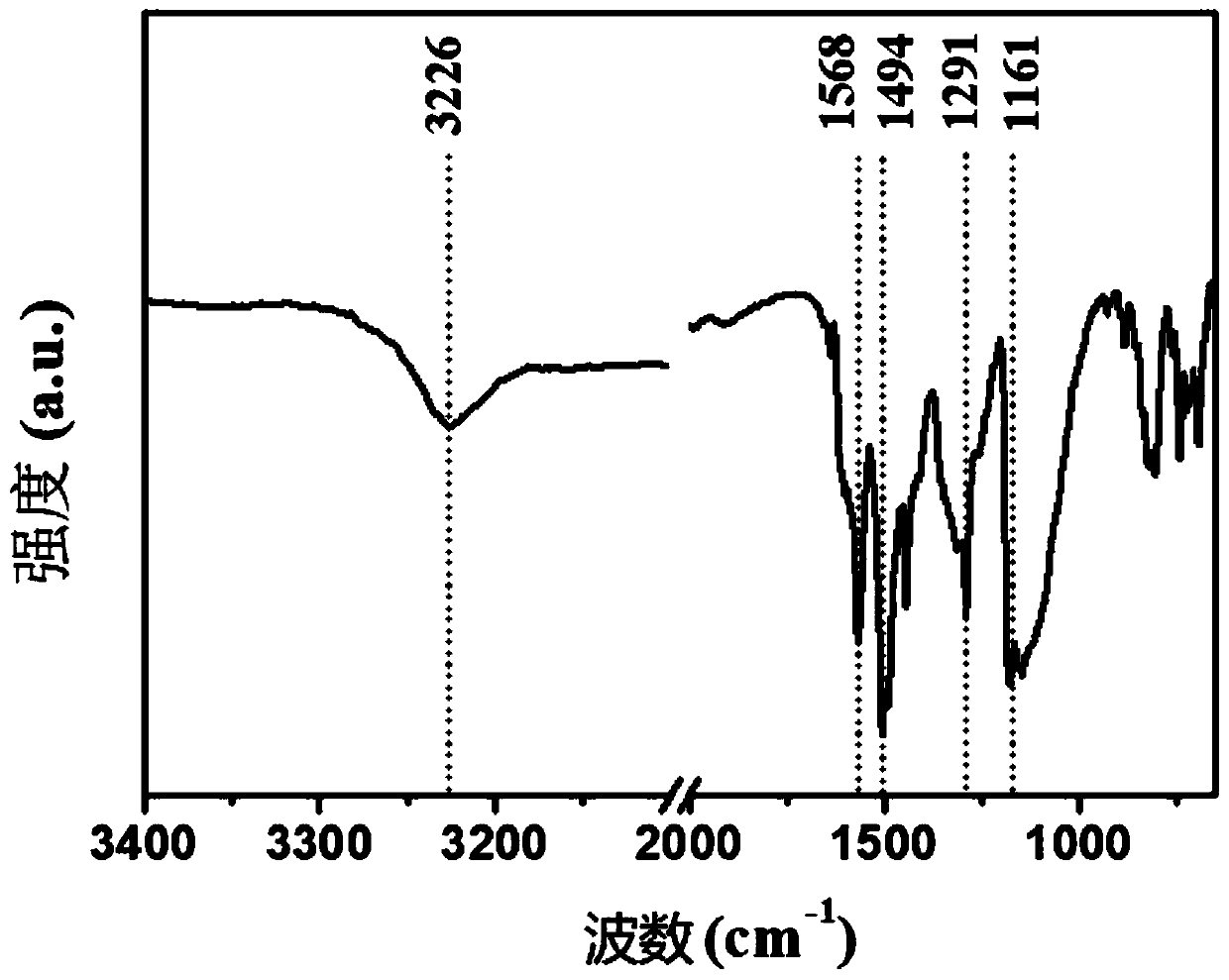

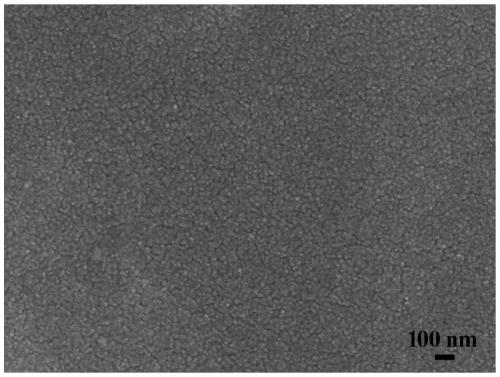

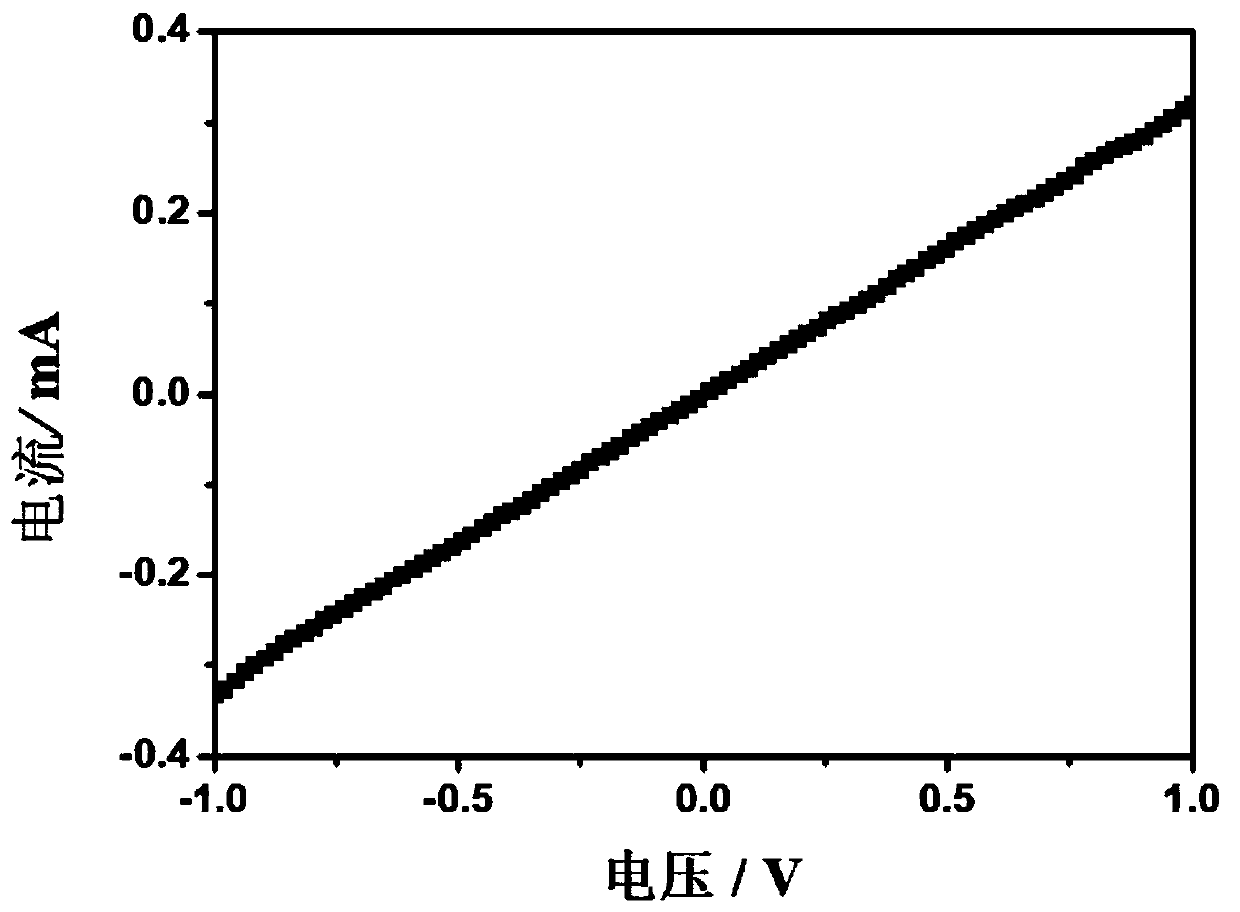

[0024] Embodiment 1: In this embodiment, a method for preparing a flexible two-dimensional polyaniline film by gas diffusion is carried out according to the following steps:

[0025] 1. Mix ammonium persulfate with hydrochloric acid with a concentration of 0.1mol / L to 1mol / L, and stir magnetically for 20min to 45min to obtain ammonium persulfate solution;

[0026] The quality of described ammonium persulfate and concentration are that the volume ratio of the hydrochloric acid of 0.1mol / L~1mol / L is 1g:(0.67~2)L;

[0027] 2. Place the ammonium persulfate solution in an open container, place the aniline liquid in another open container, and then place the container containing the ammonium persulfate solution and the container containing the aniline liquid in the same closed space, Under the condition of a temperature of 1 DEG C to 10 DEG C, the gas diffusion reaction takes 1 to 10 days to obtain a flexible two-dimensional polyaniline film on the surface of the ammonium persulfate...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the mass ratio of the volume of the aniline liquid described in step 2 to the ammonium persulfate described in step 1 is (10-30) mL:1 g. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the volume of the enclosed space described in step 2 is 1L-40L. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com