Side-chain amphoteric structure polyarylethersulfone, preparation method thereof and homogeneous amphoteric ion exchange film

A technology of polyarylethersulfone and side chains, which is applied in the field of homogeneous amphoteric ion exchange membranes, and can solve the problems of reduced elongation at break, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

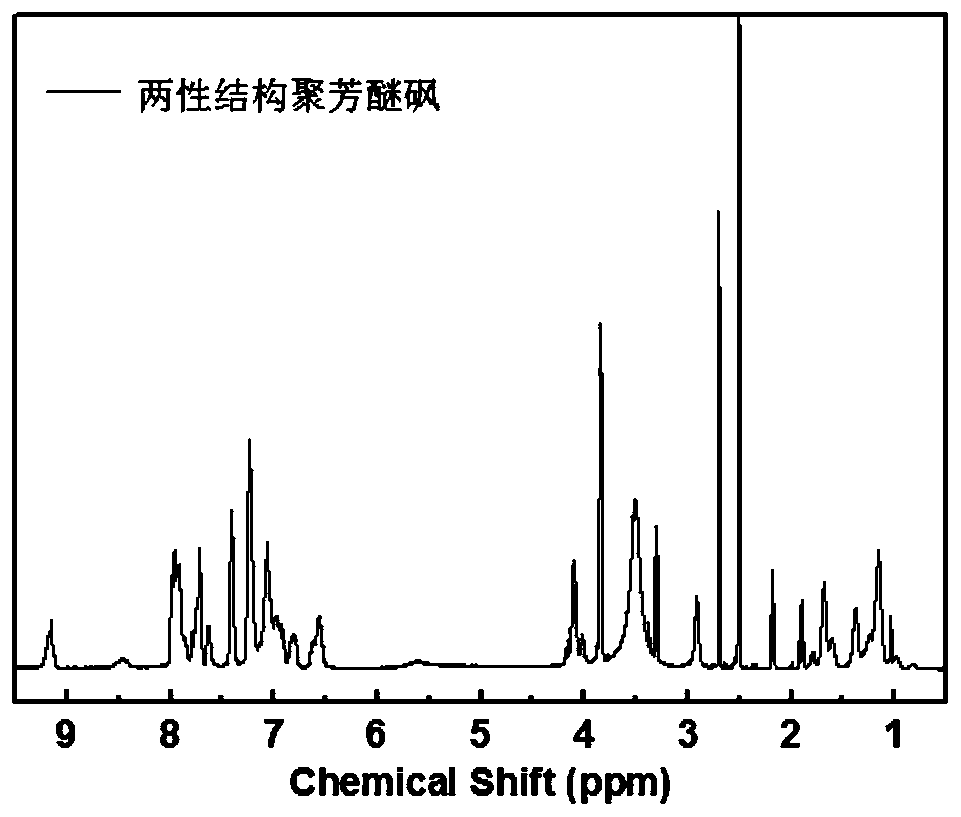

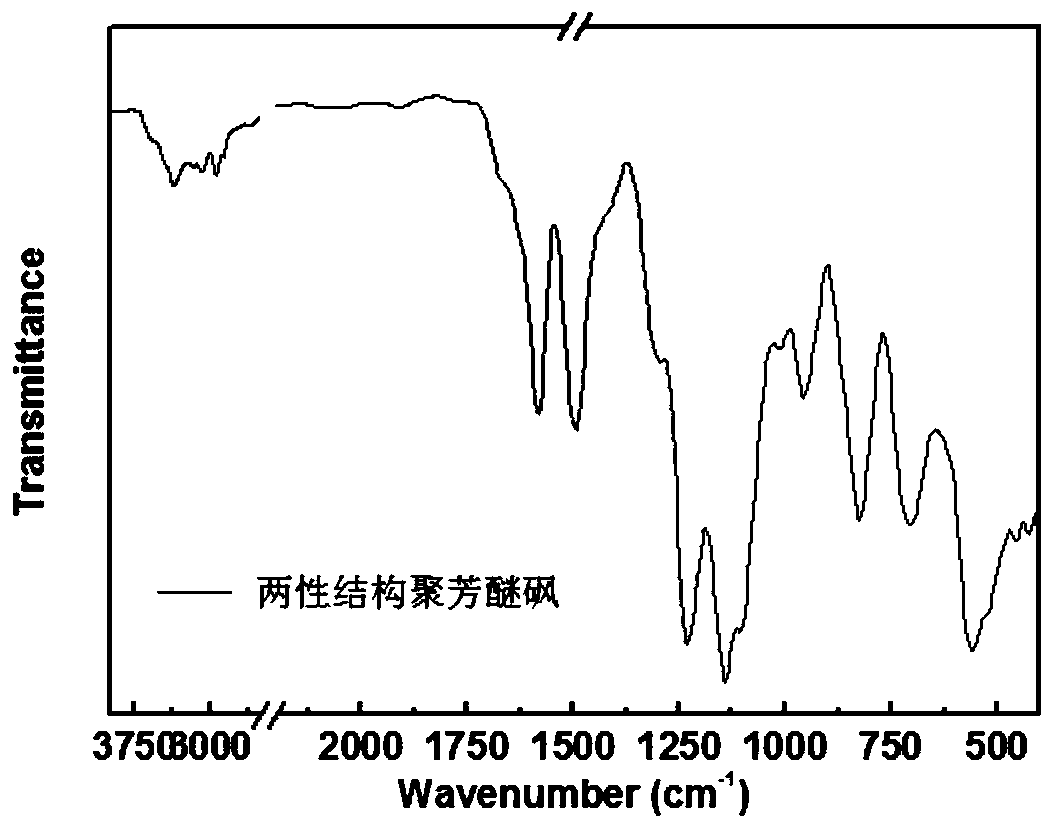

Method used

Image

Examples

Embodiment 1

[0068] Preparation of 3,3'-dibromo-4,4'-difluorodiphenylsulfone (db-DFPS): Weigh 25.4 grams of 4,4'-difluorodiphenylsulfone (0.10mol) in a 250mL round bottom flask , and then add 150mL of concentrated sulfuric acid, stir and dissolve at 25°C in a nitrogen atmosphere. Then, 14.2 g (0.22 mol) of N-bromosuccinimide (NBS) was added in batches in 3 batches, with an interval of 15 min between each batch, and rapid stirring was maintained for 6 h. The resulting mixture was poured into 500 mL of ice water. The precipitate was obtained by filtration, and then washed with 600 mL of deionized water and 100 mL of n-hexane, respectively. Finally, it is purified by crystallization from toluene. Vacuum drying at 60°C for 12 hours yielded 18.3 g of db-DFPS.

[0069] Preparation of bis(4-fluoro-3-(3-butenoic acid sodium)phenyl)sulfone (m-DFPS): Weigh 8.0 g (19.4 mmol) of 3,3'dibromo-4,4'difluorobis Phenylsulfone, 4.70 grams (41.2 mmol) of sodium 3-butenoate, 0.262 grams (1.07 mmol) of pall...

Embodiment 1-2

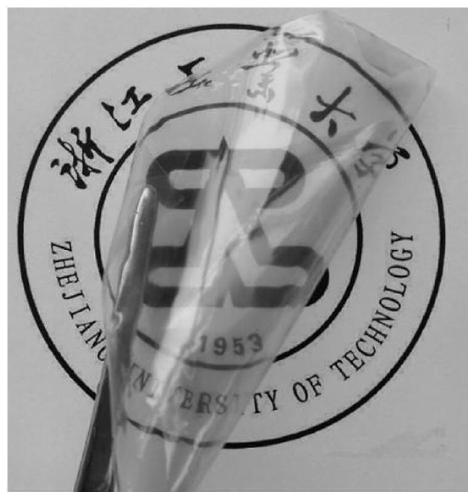

[0075] Preparation of side-chain type polyarylethersulfone amphoteric ion exchange membrane: 2.8 g of side-chain type amphoteric polyarylethersulfone prepared in Example 1 was dissolved in 60 mL of NMP solvent, mechanically stirred at 80°C until completely dissolved, Obtain the casting solution; degas the casting solution in vacuum, then pour the defoamed casting solution into a clean glass mold, dry it at 80°C to form a film, and vacuum dry it at 100°C to obtain a homogeneous side chain Type polyaryl ether sulfone amphoteric ion exchange membrane, the film thickness is 121μm (see image 3 ). The obtained amphoteric ion exchange membrane was soaked in 1.0M hydrochloric acid for 24 hours to convert the sodium form to the acid form, and soaked in deionized water for use.

[0076] Using the national standard method, it can be known through experiments that the IEC of the prepared side chain type polyaryl ether sulfone amphoteric ion exchange membrane is 2.21mmol g –1 , surface ...

Embodiment 2

[0078] Preparation of 3,3'-dibromo-4,4'-difluorodiphenylsulfone (db-DFPS): The same preparation process as in Example 1 was used to obtain db-DFPS.

[0079] Preparation of two (4-fluoro-3-(3-butenoic acid sodium) phenyl) sulfone (m-DFPS): using the same preparation process as in Example 1, two (4-fluoro-3-(3-butane) Sodium enoate) phenyl) sulfone.

[0080] 1-bromo-6-imidazolium salt hexane chain (Br-(CH 2 ) 6 -IM) Synthesis: Using the same preparation process as in Example 1, pure 1-bromo-6-methylimidazolium salt-alkane was obtained.

[0081] Preparation of side chain type amphoteric structure polyaryl ether sulfone: adopt the same preparation process as in Example 1, the only difference is the addition of 4,4'-difluorodiphenyl sulfone (9 mmol), bis(4-fluoro-3-(3 -sodium crotonate)phenyl)sulfone (1mmol) to give 10% molar content of bis(4-fluoro-3-(3-butenoate sodium)phenyl)sulfone, 2,2'-bis(3-amino The molar content of -4-hydroxyphenyl) hexafluoropropane is 7.8 grams of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com