Homologous metal gradient material and preparation method and application thereof

A gradient material and metal technology, applied in chemical instruments and methods, catalyst activation/preparation, electrodes, etc., can solve the problems of precious metal platinum resources such as scarcity, unsuitability, and high price, and achieve excellent electrocatalytic hydrogen evolution performance and optimized hydrogen adsorption Good performance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

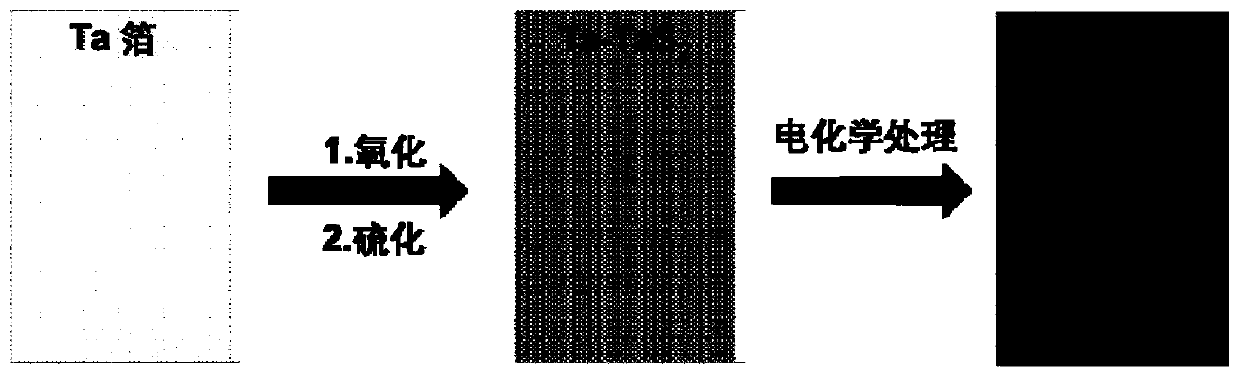

[0046] see figure 1 , figure 1 It is a schematic diagram of the principle of preparing a homogeneous metal gradient material in this embodiment. This embodiment provides a homogeneous metal gradient material, which is prepared according to the following steps:

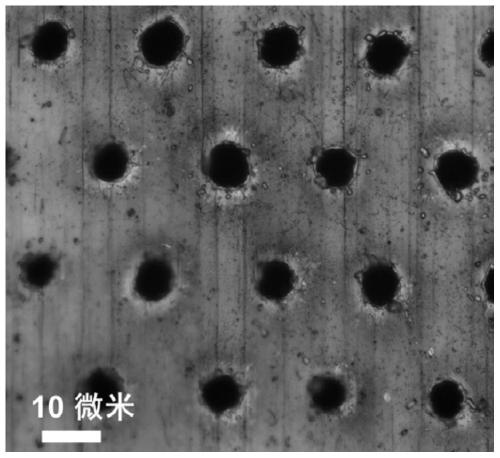

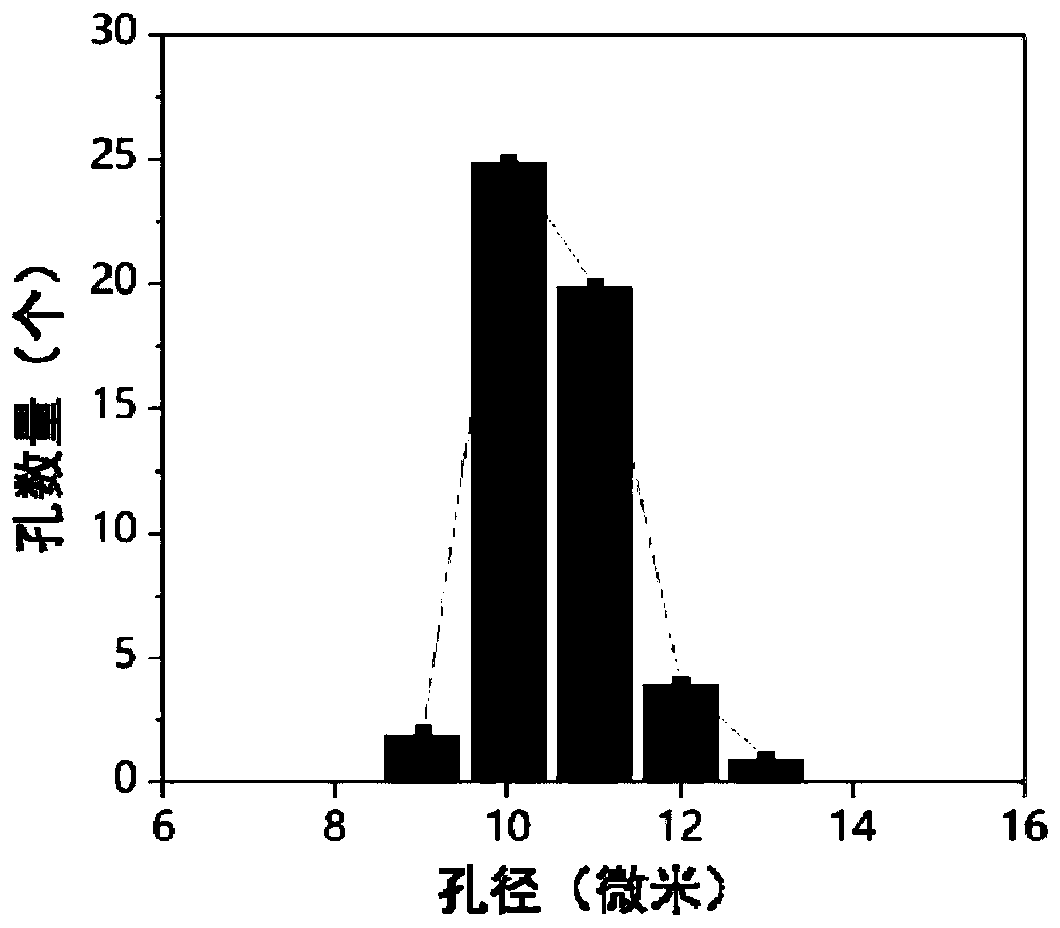

[0047] (1) Take metal tantalum foil (Ta foil, 2 cm x 2 cm), flatten it with a tablet machine, and then use laser technology to make holes to form porous metal tantalum foil, and carry out in the area of 1 cm x 1 cm of Ta foil Make pores with a diameter of 10 microns. Then use ethanol and water to ultrasonically clean in sequence, blow dry with a nitrogen gun, and package under inert atmosphere conditions for use.

[0048] (2) Take the above-mentioned porous metal tantalum foil and place it in a high-temperature heating furnace for chemical oxidation treatment, raise the temperature in the furnace to 500°C, the heating rate is 10°C / min, keep the temperature at 500°C for 15 minutes, stop heating and let the furnace c...

Embodiment 2

[0060] This embodiment provides a homologous metal (Ta) gradient material (Ta-TaS) treated by electrochemical cyclic voltammetry. 2 ), other conditions and steps are the same as in Example 1, the difference is that step (1) is: take metal tantalum foil (2 × 2 cm), flatten it with a tablet press, and use laser technology to make holes to form porous metal tantalum Foil, make holes in the area of 1 cm × 1 cm in the Ta foil, with a pore size of 50 microns. Ultrasonic cleaning with ethanol and water in sequence, drying with a nitrogen gun, and packaging under inert atmosphere conditions for use.

[0061] Figure 11 This is the pore size distribution diagram of the porous metal tantalum foil prepared in step (1) of this example. The sample pore size of the porous metal tantalum foil is about 50 microns, and the difference in pore size is within ±4 microns.

[0062] Figure 12 The homologous metal (Ta) gradient material (Ta-TaS) processed by electrochemical cyclic voltammetry f...

Embodiment 3

[0064] This embodiment provides a homologous metal (Ta) gradient material (Ta-TaS) treated by electrochemical cyclic voltammetry. 2 ), other conditions and steps are the same as in Example 1, except that step (4) is: the tantalum-tantalum sulfide sample obtained in step (3) is placed in the electrode holder as the cathode, the graphite rod is the anode, and the Ag The / AgCl electrode is the reference electrode, and the electrolyte is 0.5MH 2 SO 4 . Electrochemical cyclic voltammetry was used for processing, the scanning speed was set to 20mV / min, and the number of scanning was 5000 times. After the treatment is completed, the homogeneous metal (Ta) gradient material treated by electrochemical cyclic voltammetry is taken out, washed with a large amount of deionized water, dried with a nitrogen gun, and packaged under an inert atmosphere for use.

[0065] Figure 13 The homologous metal (Ta) gradient material (Ta-TaS) processed by electrochemical cyclic voltammetry for embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com