Antibacterial optically variable polyvinyl chloride wig fiber and preparation method thereof

A technology of polyvinyl chloride and chlorinated polyvinyl chloride, applied in wigs, microsphere preparation, fiber chemical characteristics, etc., can solve the problems of single color, rigidity, and inactivity of wig fibers, achieve good photosensitive performance, and improve heat resistance Antibacterial properties, strong broad-spectrum antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

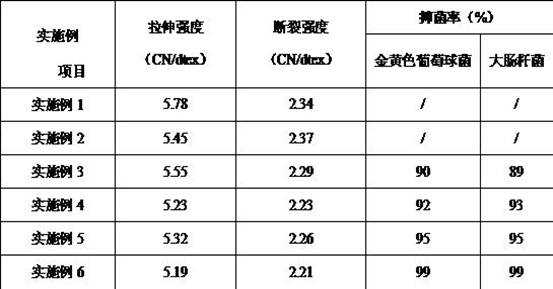

Embodiment 1

[0025] An antibacterial light-changing polyvinyl chloride wig fiber, comprising the following raw materials in parts by weight: 57.7 parts of polyvinyl chloride with a degree of polymerization of 1000-1100 and a K value of 66.3-67.4, and 11 parts of chlorinated polyvinyl chloride with a chlorine content of 68.4%. 27 parts of n-butyl acetate, 1.6 parts of calcium zinc stabilizer, 2 parts of anti-impact agent MBS, 8 parts of diisononyl cyclohexane-1,2-dicarboxylate, 8 parts of photochromic microcapsule toner, 7 parts of silica, 1 part of acrylic acid.

Embodiment 2

[0027] An antibacterial light-changing polyvinyl chloride wig fiber, comprising the following raw materials in parts by weight: 60 parts of polyvinyl chloride with a degree of polymerization of 1000-1100 and a K value of 65.7-67.7, and 11 parts of chlorinated polyvinyl chloride with a chlorine content of 68.4%. 30 parts of n-butyl acetate, 3 parts of epoxidized soybean oil, 1.2 parts of anti-impact agent MBS, 9 parts of diisononyl cyclohexane-1,2-dicarboxylate, 8 parts of photochromic microcapsule toner, 7 parts of calcium carbonate, 1.2 parts of acrylic acid.

Embodiment 3

[0029] An antibacterial light-changing polyvinyl chloride wig fiber, comprising the following raw materials in parts by weight: 57.7 parts of polyvinyl chloride with a degree of polymerization, 13 parts of chlorinated polyvinyl chloride, 27 parts of n-butyl acetate, 3 parts of calcium zinc stabilizer, anti- 0.8 parts of MBS granule, 9 parts of diisononyl cyclohexane-1,2-dicarboxylate, 8 parts of photochromic microcapsule toner, 7 parts of silicon dioxide, 1 part of acrylic acid; also includes 10 parts of antibacterial agent; The antibacterial agent is made of tea polyphenols, chitosan, cassia, clove and honeysuckle in a weight ratio of 10:5:6:2:2; the photosensitive color-changing microcapsule toner is made of polyurethane- Urea resin, WO 3 and TiO 2 Made; Polyurethane-urea resin has urea bonds in its molecular chain and no isocyanate groups at its molecular ends.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com