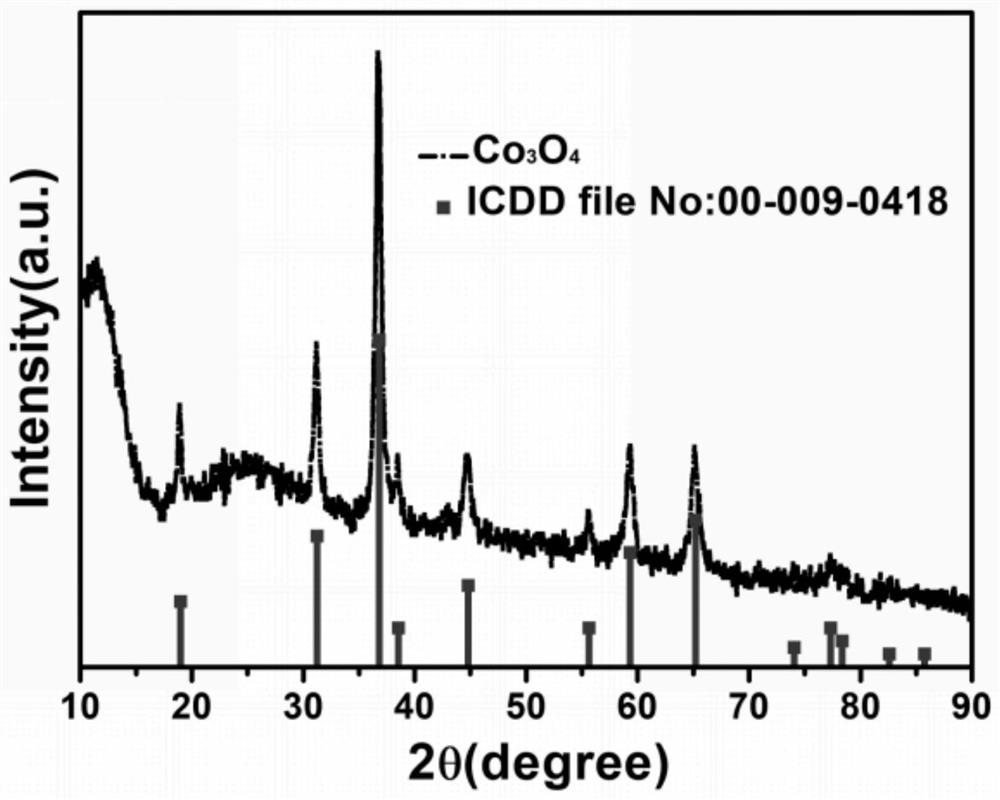

A lithium battery negative electrode material co 3 o 4 Preparation method of nanofiber

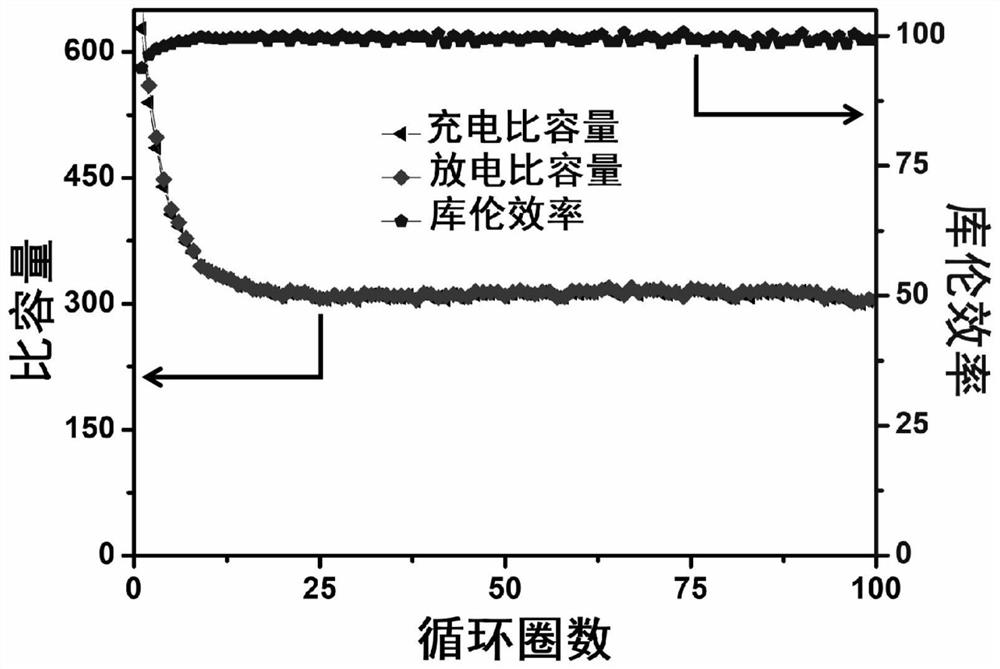

A negative electrode material and nanofiber technology, applied in the field of preparation of lithium battery negative electrode material Co3O4 nanofibers, can solve the problems of poor cycle durability, battery material falling off, hindering negative electrode materials, etc., to improve electrical conductivity, alleviate negative effects, and improve electrical conductivity. The effect of performance and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

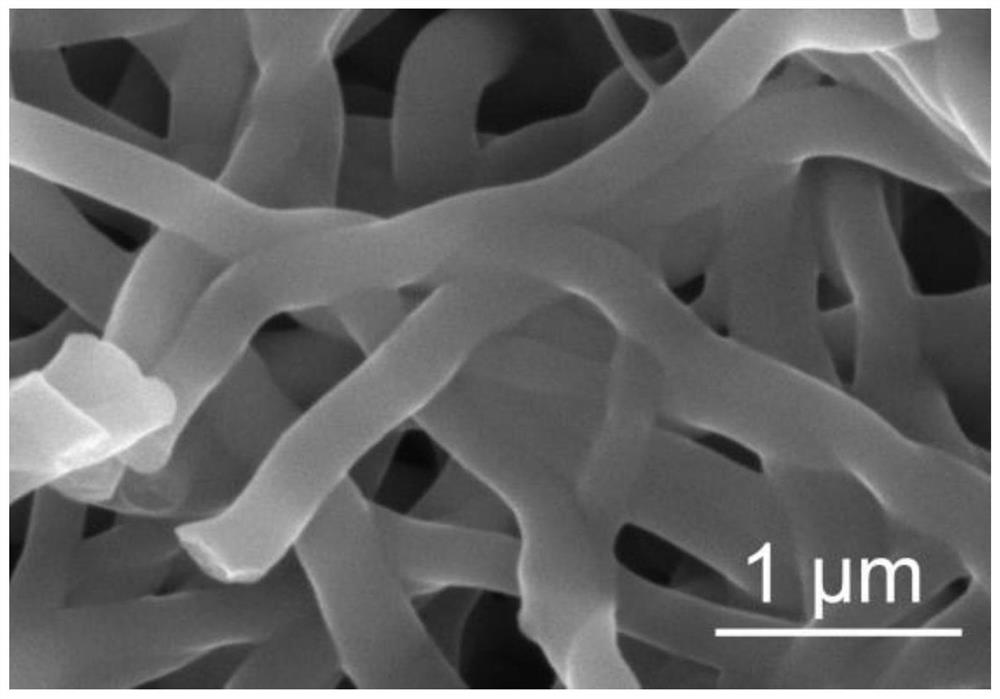

Embodiment 1

[0024] Add 20mL N,N-dimethylformamide in the beaker as solvent, then add 1mmoL (0.2903g) trimethoprim (C 14 h 18 N 4 o 3 ) and 1mmoL (0.2491g) cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 0), magnetic stirring 1h, solid is dissolved completely; In beaker, add 1.42g polyacrylonitrile (PAN) again as binding agent, magnetic stirring 2h, obtain the red spinning precursor solution; The red spinning precursor solution Loaded into a 10mL syringe, at a voltage of 18kV, the distance between the spinning needle and the receiver is 15cm, and the push flow rate is 1.1mL h -1, the temperature was 35°C, and the relative humidity of the cabinet was 35% for electrospinning. After spinning for 12 hours, the spinning product was collected and dried in a vacuum drying oven at 60°C for 1 hour to obtain the dried electrostatic spinning product; Add 60mL of methanol and 6mmol, 1.5g of cobalt acetate tetrahydrate into a 100mL beaker, and magnetically stir for 1 hour to completely dissolve ...

Embodiment 2

[0026] Add 20mL N,N-dimethylformamide in the beaker as solvent, then add 1mmoL (0.2903g) trimethoprim (C 14 h 18 N 4 o 3 ) and 1mmoL (0.2491g) cobalt acetate tetrahydrate (C 4 h 6 CoO 4 4H 2 0), magnetic stirring 1h, solid is dissolved completely; In beaker, add 1.42g polyacrylonitrile (PAN) again as binding agent, magnetic stirring 2h, obtain the red spinning precursor solution; The red spinning precursor solution Loaded into a 10mL syringe, at a voltage of 20kV, the distance between the spinning needle and the receiver is 25cm, and the push flow rate is 1.1mL h -1 , the temperature was 35°C, and the relative humidity of the cabinet was 35% for electrospinning. After spinning for 12 hours, the spinning product was collected and dried in a vacuum drying oven at 60°C for 1 hour to obtain the dried electrostatic spinning product; Add 60mL of methanol and 6mmol, 1.5g of cobalt acetate tetrahydrate into a 100mL beaker, and magnetically stir for 1 hour to completely dissolve...

Embodiment 3

[0028] Add 20mL N,N-dimethylformamide in the beaker as solvent, then add 1mmoL (0.2903g) trimethoprim (C 14 h 18 N 4 o 3 ) and 1mmoL (0.2491g) cobalt acetate tetrahydrate (C 4 h 6 COO 4 4H 2 0), magnetic stirring 1h, solid is dissolved completely; In beaker, add 1.42g polyacrylonitrile (PAN) again as binding agent, magnetic stirring 2h, obtain the red spinning precursor solution; The red spinning precursor solution Loaded into a 10mL syringe, at a voltage of 19kV, the distance between the spinning needle and the receiver is 20cm, and the push flow rate is 1.1mL h -1 , the temperature is 35 ℃, and the relative humidity of the cabinet is 35% to carry out electrospinning. After spinning for 12 hours, the spinning product is collected and dried in a vacuum drying oven at 60 ℃ for 1 hour to obtain the dried electrostatic spinning product; Add 60mL of methanol and 6mmol, 1.5g of cobalt acetate tetrahydrate into a 100mL beaker, and magnetically stir for 1 hour to completely di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com