Micromolecular zwitterion modified surface polyamide composite membrane and preparation method thereof

A technology of surface polyamide and zwitterions, which is applied in semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problems of membrane pollution, increased operating costs, permeate flux and quality reduction required by industrialization, and achieve faster Effects of mass transfer, improved hydrophilicity, and high rejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

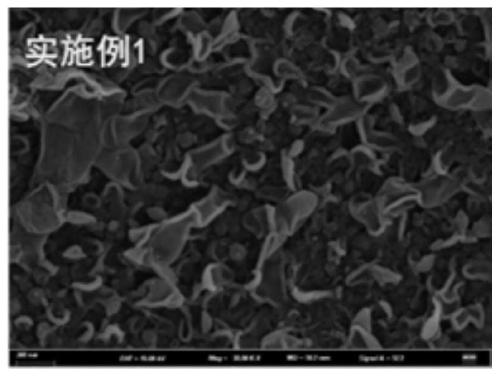

Embodiment 1

[0056] A small molecule zwitterion modified surface polyamide composite membrane, the polyamide composite membrane includes an ultrafiltration bottom membrane and a polyamide layer modified by small molecules, and the polyamide layer covers the surface of the ultrafiltration bottom membrane;

[0057] The small molecule is 3-((2-((4-aminophenyl)amino)-ethyl)dimethyl)propane-1-sulfonate.

[0058] The preparation method of the described small molecule zwitterion modified surface polyamide composite membrane comprises the following steps:

[0059] (1) Immerse the polysulfone ultrafiltration membrane in the mixed aqueous solution containing 2.4wt% camphorsulfonic acid, 1.1wt% triethylamine and 2.0wt% m-phenylenediamine for 2min, then take out and remove the water on the surface phase solution;

[0060] (2) Immerse the polysulfone ultrafiltration membrane treated in the step (1) in the n-hexane solution containing 0.1wt% trimesoyl chloride for 1min, then take out and remove the org...

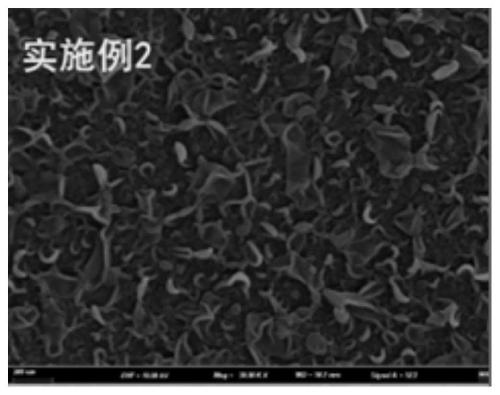

Embodiment 2

[0063] A small molecule zwitterion modified surface polyamide composite membrane, the polyamide composite membrane includes an ultrafiltration bottom membrane and a polyamide layer modified by small molecules, and the polyamide layer covers the surface of the ultrafiltration bottom membrane;

[0064] The small molecule is 3-((2-((4-aminophenyl)amino)-ethyl)dimethyl)propane-1-sulfonate.

[0065] The preparation method of the described small molecule zwitterion modified surface polyamide composite membrane comprises the following steps:

[0066] (1) Immerse the polysulfone ultrafiltration membrane in the mixed aqueous solution containing 2.4wt% camphorsulfonic acid, 1.1wt% triethylamine and 2.0wt% m-phenylenediamine for 2min, then take out and remove the water on the surface phase solution;

[0067] (2) Immerse the polysulfone ultrafiltration membrane treated in the step (1) in the n-hexane solution containing 0.1wt% trimesoyl chloride for 1min, then take out and remove the org...

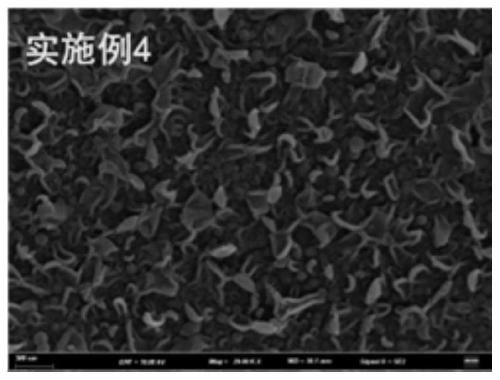

Embodiment 3

[0070] A small molecule zwitterion modified surface polyamide composite membrane, the polyamide composite membrane includes an ultrafiltration bottom membrane and a polyamide layer modified by small molecules, and the polyamide layer covers the surface of the ultrafiltration bottom membrane;

[0071] The small molecule is 3-((2-((4-aminophenyl)amino)-ethyl)dimethyl)propane-1-sulfonate.

[0072] The preparation method of the described small molecule zwitterion modified surface polyamide composite membrane comprises the following steps:

[0073] (1) Immerse the polysulfone ultrafiltration membrane in the mixed aqueous solution containing 2.4wt% camphorsulfonic acid, 1.1wt% triethylamine and 2.0wt% m-phenylenediamine for 2min, then take out and remove the water on the surface phase solution;

[0074] (2) Immerse the polysulfone ultrafiltration membrane treated in the step (1) in the n-hexane solution containing 0.1wt% trimesoyl chloride for 1min, then take out and remove the org...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com