Hyperspectral camouflage material and preparation method thereof

A hyperspectral, raw material technology, applied in the field of hyperspectral camouflage materials and their preparation, can solve the problems of poor practicability, increased material weight, easy exposure targets, etc., and achieves the effect of improving service life and improving weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

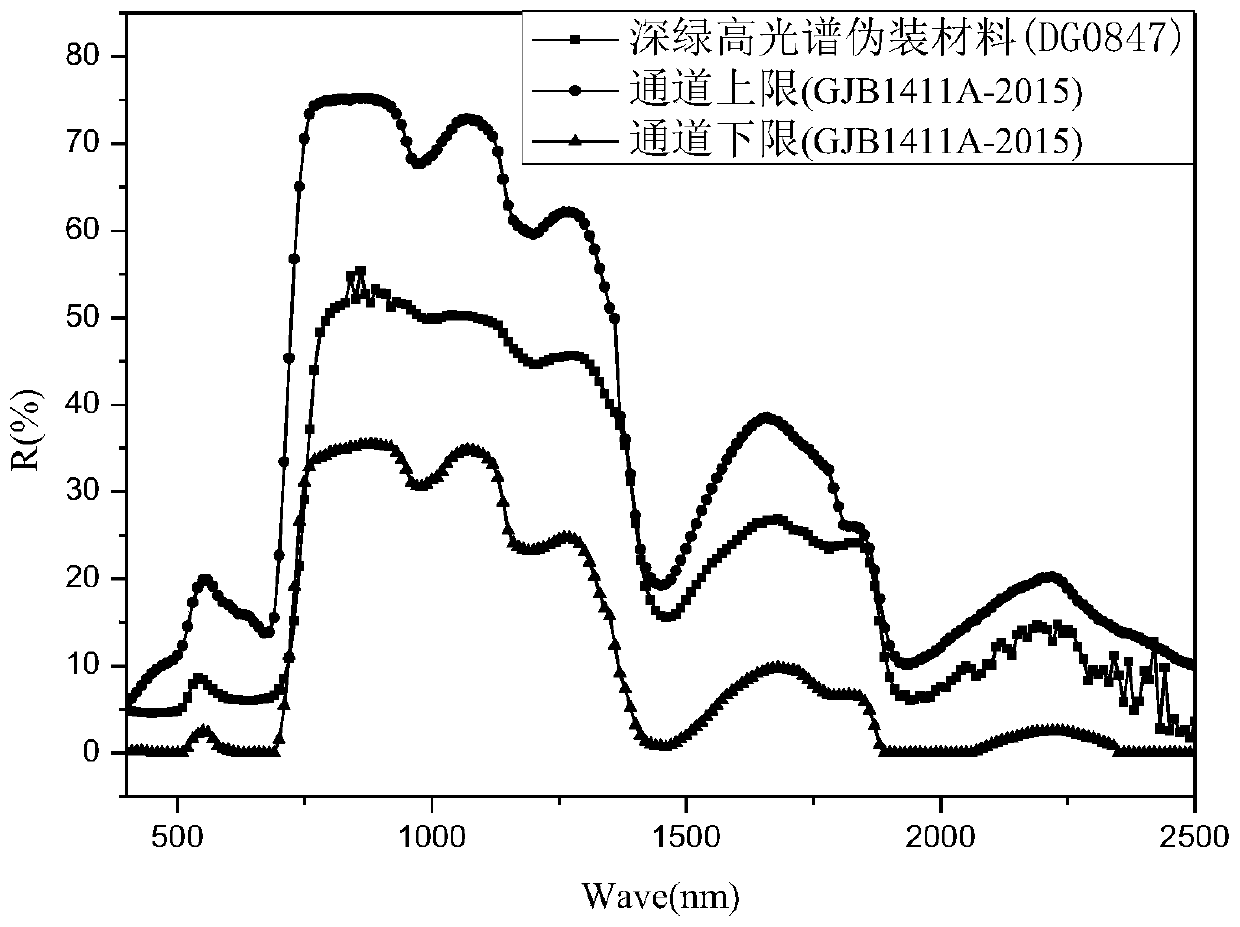

Embodiment 1

[0047] (1) Preparation of chrome green water-based monochrome paste: add 210 parts of deionized water in the mixing tank, add 2 parts of wetting agent, 32 parts of dispersant, 1.4 parts of defoamer, 0.15 part of HEC ( Hydroxyethyl cellulose), after stirring for 5 minutes, add 81 parts of chrome green powder, continue to stir for 30 minutes, and grind with a horizontal sand mill. The filling rate of the grinding medium of the sand mill is 0.82. 1.0mm, feeding pressure 0.8MPa, circular grinding, until the fineness of the coating is ground to 25-30 microns, stop grinding;

[0048] (2) Preparation of perylene black water-based monochrome paste: perylene black water-based monochrome paste uses perylene black powder, and the other is the same as the formula and process for preparing chrome green water-based monochrome paste;

[0049] (3) Preparation of titanium white water-based monochrome paste: add 260 parts of deionized water into the mixing tank, add 2 parts of wetting agent, 3 ...

Embodiment 2

[0071] Implementation according to step in embodiment 1, formula is as shown in the following table:

[0072] Water-based monochrome paste formula and implementation process are the same as embodiment 1;

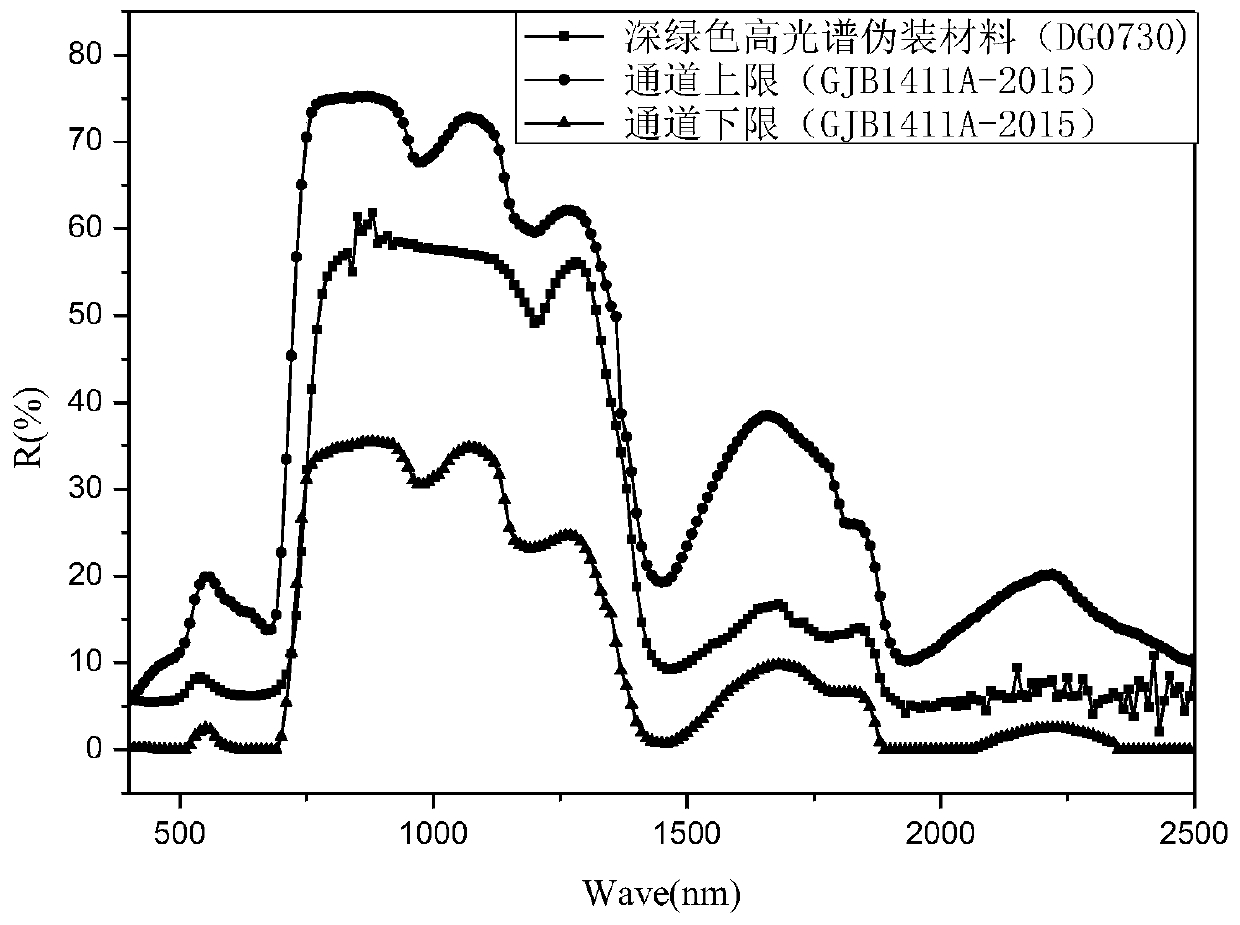

[0073] The formula of dark green (DG0730) hyperspectral material is shown in the table below:

[0074] formula Ratio (parts) Hyperspectral Material Matrix 100 Chrome green water-based monochrome paste 1.5 Perylene black water-based monochrome paste 1.0 Permanent yellow water-based monochrome paste 1.5

[0075] figure 2 Shown is the spectral reflectance curve of the dark green (DG0730) hyperspectral camouflage material and the GJB1141A-2015 channel. The spectral reflectance curve of the dark green (DG0730) hyperspectral camouflage material is in an indoor environment (temperature 30°C, humidity figure 2 It can be seen that the dark green (DG0730) hyperspectral camouflage material complies with the GJB 1411A-2015 channel requirements,...

Embodiment 3

[0080] Implementation according to step in embodiment 1, formula is as shown in the following table:

[0081] Water-based monochrome paste formula and implementation process are the same as embodiment 1;

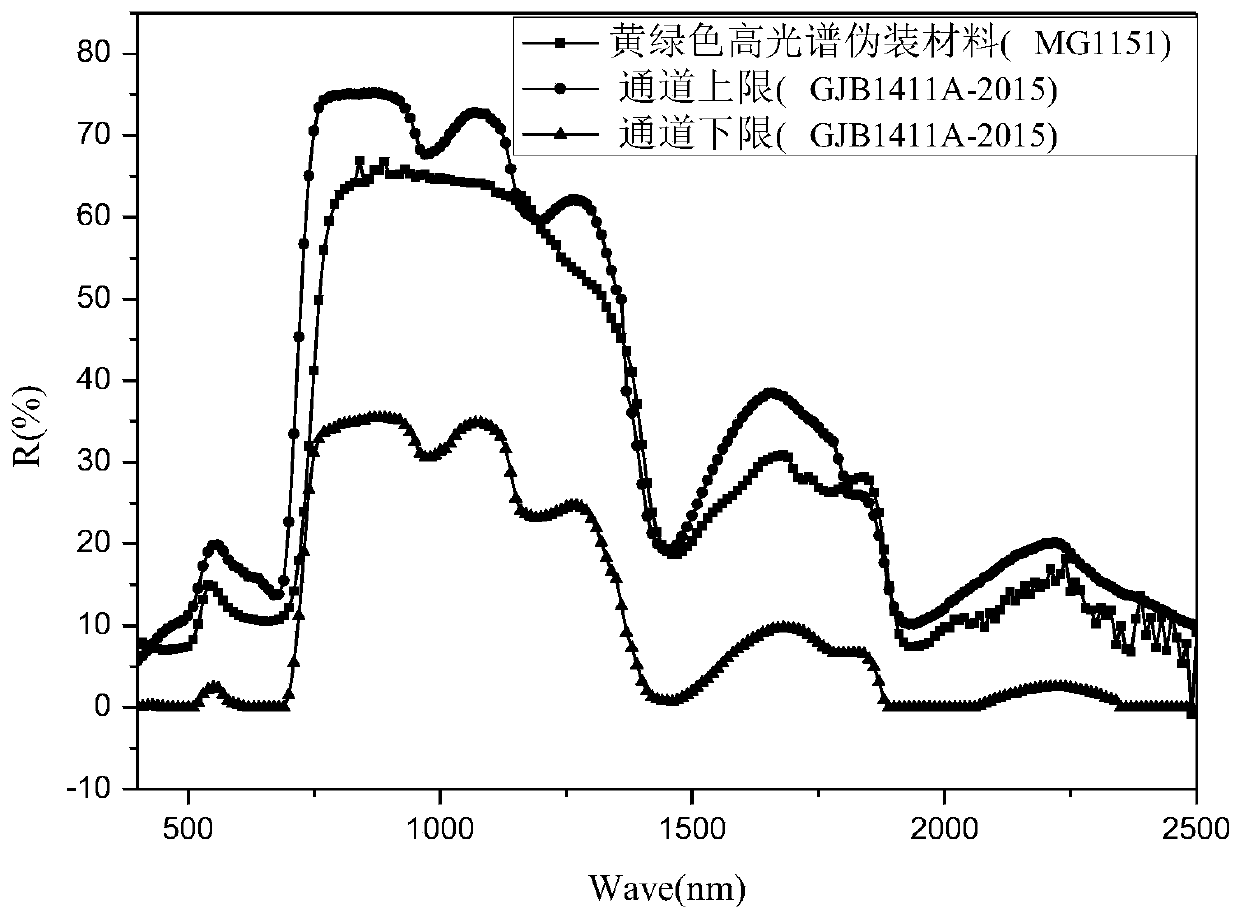

[0082] The formula of yellow-green (MG1151) hyperspectral material is shown in the table below:

[0083] formula Ratio (parts) Hyperspectral Material Matrix 100 Chrome green water-based monochrome paste 10 Perylene black water-based monochrome paste 4.5 Titanium white water-based monochrome paste 1.9 Permanent yellow water-based monochrome paste 5.0

[0084] image 3 Shown is the spectral reflectance curve of the yellow-green (MG1151) hyperspectral camouflage material and the GJB1141A-2015 channel. The spectral reflectance curve of the yellow-green (MG1151) hyperspectral camouflage material is in an indoor environment (temperature 30 ° C, humidity figure 2 It can be seen that the yellow-green (MG1151) hyperspectral camouflage m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com