Organic polymer flow battery system

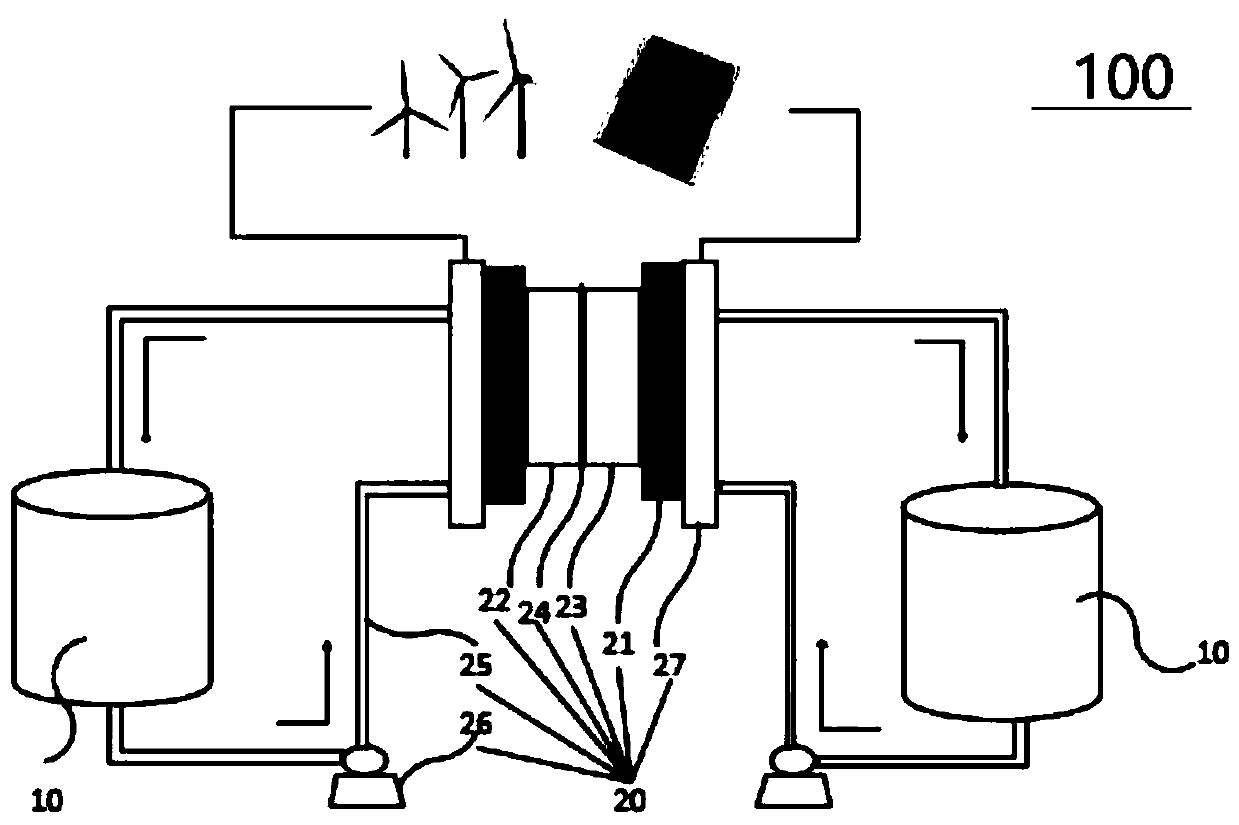

A technology of flow battery and flow battery stack, applied in fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of poor stability, low energy efficiency, environmental pollution, etc., and achieve stable charging and discharging performance and high energy density. , the effect of high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Preparation of Poly(TEMPO-co-VIMS) Copolymers by One-Pot Method

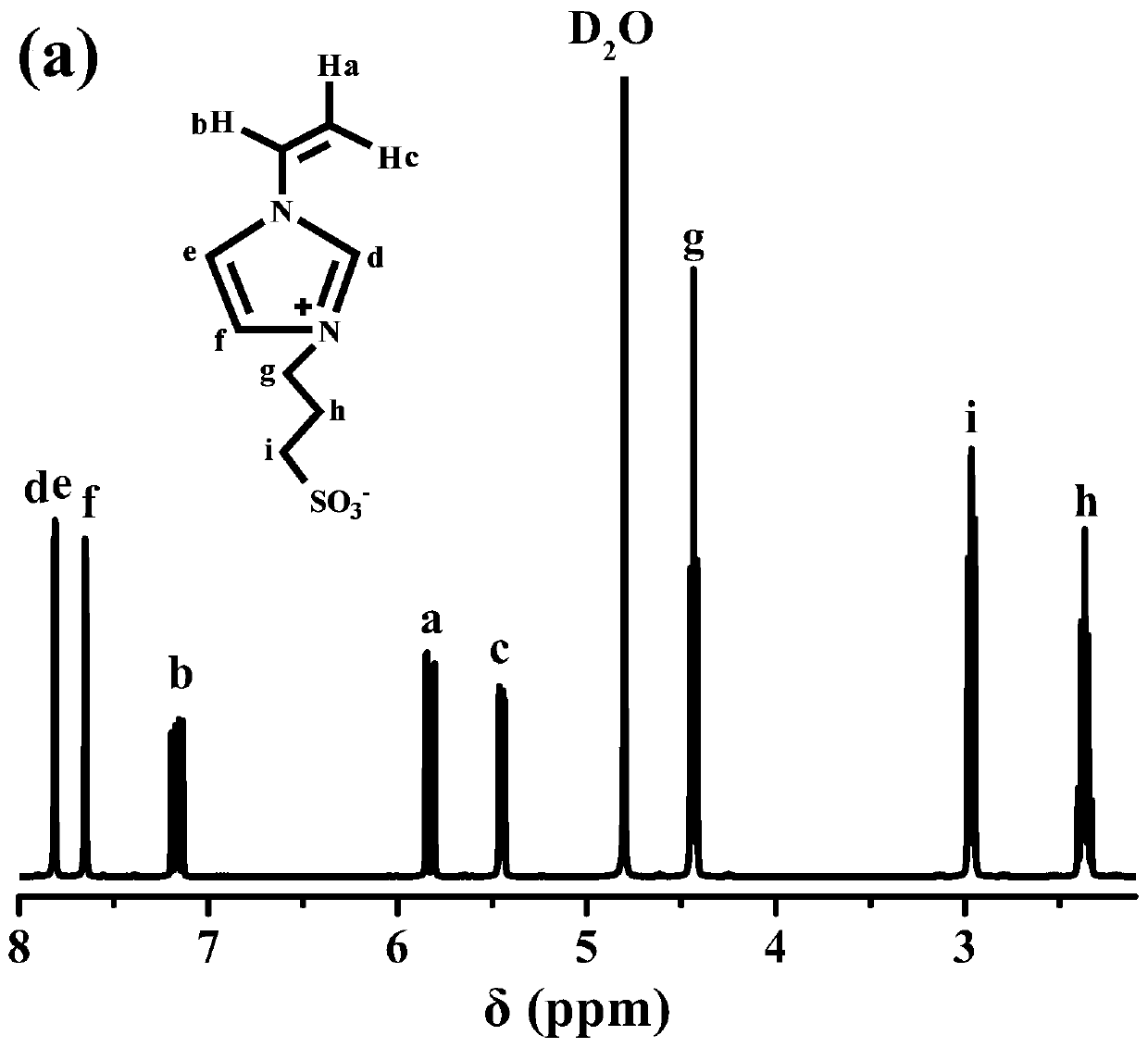

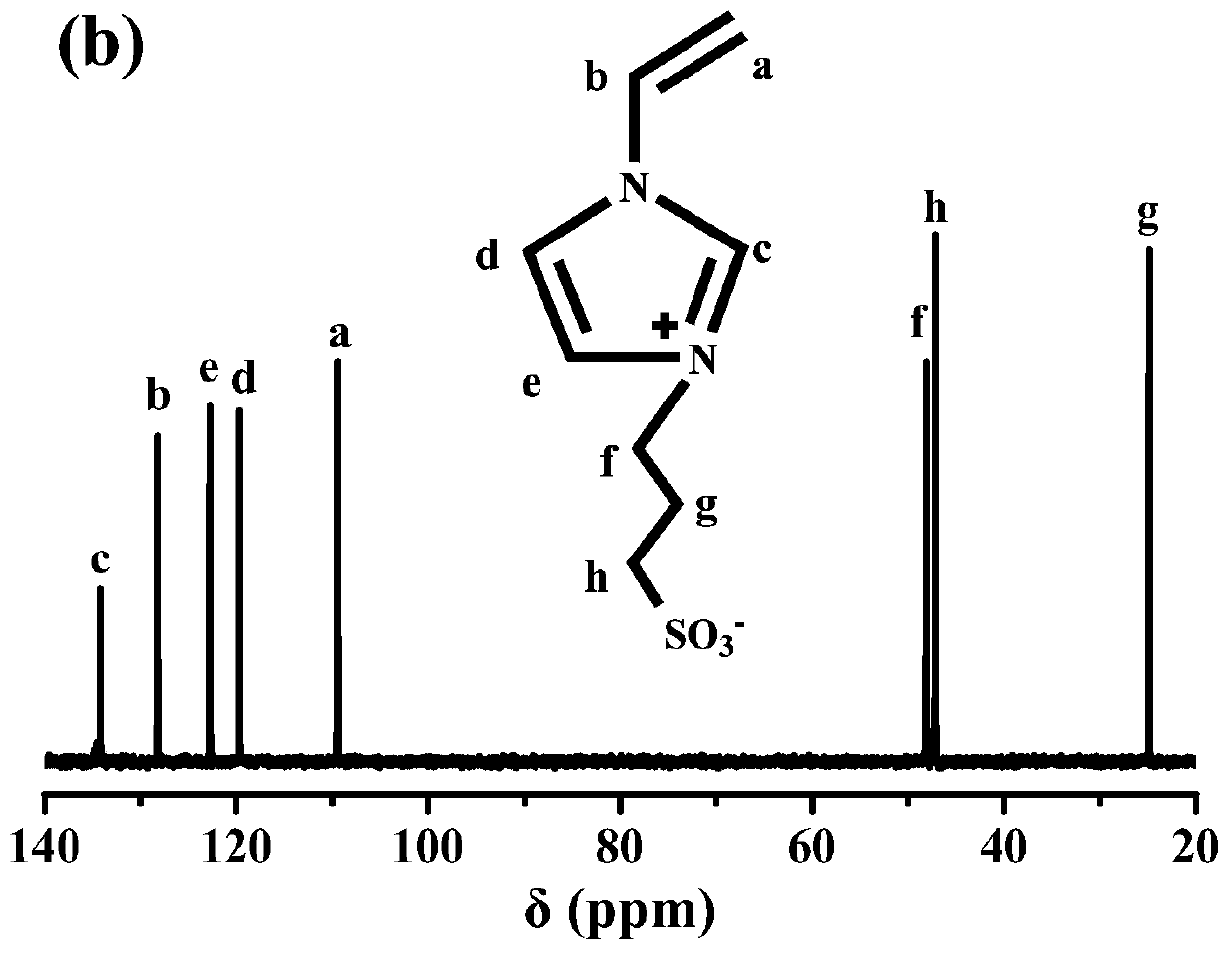

[0097] First, add 4.53 mL of light yellow liquid 1-vinylimidazole (VIM, 0.05 mol), 5.27 mL of light yellow liquid 1,3-propane sultone (0.06 mol) and 50 mL of acetonitrile solvent into the three-necked flask, in N 2 Stirring reaction at 75°C under atmosphere for 1 hour gradually produced white precipitate, and continued reaction for 4 hours until complete reaction. The resulting reaction solution was suction-filtered, washed three times, and finally dried in vacuum to obtain 9.6975 g of white powdery solid particles (named VIMS, yield 89.8%). The reaction principle is shown in the chemical reaction formula (1).

[0098] Then, add 0.9014g white solid 2-methyl-2-propenoic acid-2,2,6,6-tetramethyl-4-piperidine methyl ester (TEMPMA, 8mmol) in the three-necked flask, add a certain amount of white Solid VIMS (4 or 8mmol, 0.8560 / 1.7300g), then add 50mL deionized water, N 2 Under atmosphere, heat and stir at 7...

Embodiment 2

[0100] Preparation of Poly(CVBD) Copolymers by One-Pot Method

[0101] First, VBD (5mmol, 1.5380g) was added into a two-necked flask, light yellow liquid 3-chloro-2-hydroxypropyltrimethylammonium oxide (6mmol, 1500uL) was added, 50mL ethanol solvent was added, and the 2 After condensing and reacting at 95°C for 48 hours under atmosphere, the condensing and reflux was stopped to completely evaporate the methanol solvent to obtain an orange-red off-white solid, which was washed three times with acetonitrile, suction filtered, and vacuum-dried to finally obtain an orange-red solid 1.1378g 3-((4 -Vinylbenzyl)-[4,4'-bipyridyl]-1,1'-diumyl)propane-1-sulfonic acid chloride (CVBD), weighed in 46% yield. The reaction principle is shown in the chemical reaction formula (3).

[0102] Then, add CVBD monomer (4mmol, 1.9800g) and 50mL deionized water solvent into the two-necked flask, and keep filling with N at 70°C 2 Atmosphere for 30min, then inject 1ml of APS initiator (50mg) aqueous s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com