Solid alkali adsorbent and method for regenerating performance of natural ester insulating oil after operation

An adsorbent and solid alkali technology, which is applied in the field of solid alkali adsorbent and natural ester insulating oil performance regeneration after operation, can solve the chemical indicators that affect the acid value and water content of natural ester insulating oil, and affect the impact of natural ester insulating oil Breakthrough voltage and volume resistivity, affecting the safety performance of vegetable oil transformers, etc., to achieve good performance recovery, excellent recovery effect, easy to achieve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

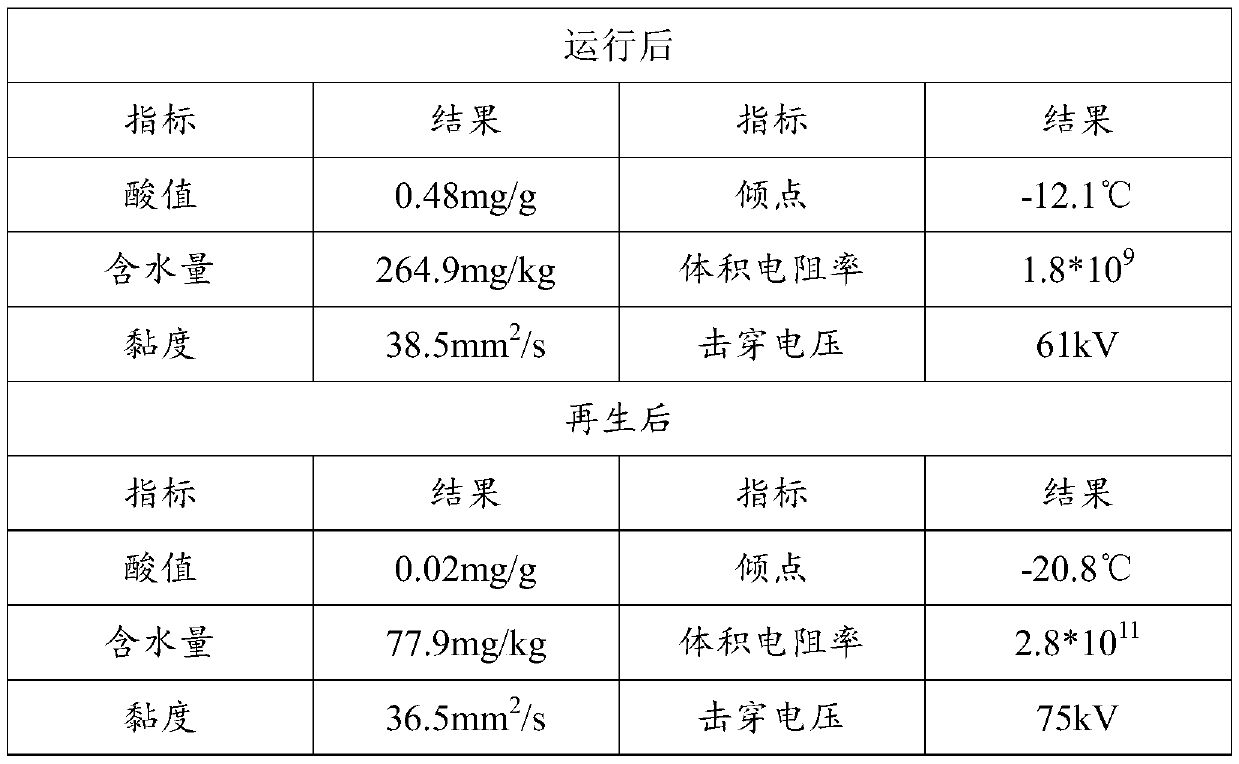

Embodiment 1

[0049] Preparation of solid alkali adsorbent: mix the powders of calcium oxide, magnesium carbonate, sodium silicate, and talcum powder according to the mass ratio of 5:3:1:1, put them into a ball mill to grind until they are completely mixed, and then put them into a muffle furnace for calcination. The calcination temperature is 500° C., the calcination time is 7 hours, and the ball mill is used after cooling.

[0050] Forming of solid alkali adsorbent: mix the ground powder with 10% polyvinyl alcohol solution, mix it into a hard mud, put it into a mold and press it into a certain shape, and then follow a certain calcination rate of 5°C / min to 900°C, keep warm for 3 hours, and take out the adsorbent after cooling.

Embodiment 2

[0052] Preparation of solid alkali adsorbent: mix the powders of calcium oxide, magnesium carbonate, sodium silicate, and talcum powder according to the mass ratio of 4:3:1:1, put them into a ball mill to grind until they are completely mixed, and then put them into a muffle furnace for calcination. The calcination temperature is 450° C., the calcination time is 6 hours, and the ball mill is used after cooling.

[0053] Forming of solid alkali adsorbent: mix the ground powder with 10% polyvinyl alcohol solution, mix it into a hard mud, put it into a mold and press it into a certain shape, and then follow a certain calcination rate of 4°C / min to 850°C, keep warm for 3 hours, and take out the adsorbent after cooling.

Embodiment 3

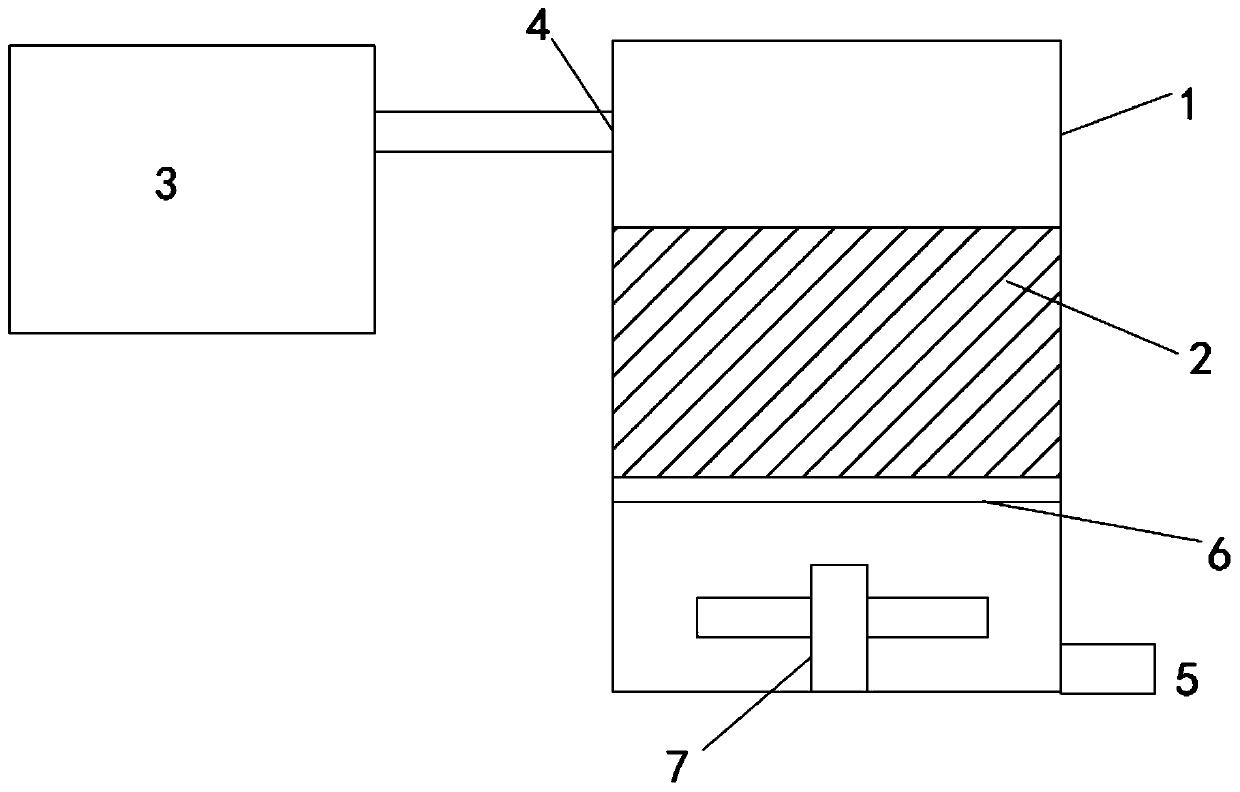

[0055] The natural ester insulating oil regeneration device includes a reactor 1, an adsorbent filling layer 2 is arranged inside the reactor 1, a filter layer 6 is arranged inside the reactor 1, and the filter layer 6 is arranged at the bottom of the adsorbent filling layer 2 , the reactor 1 is provided with an oil inlet 4, and the oil inlet 4 is arranged above the adsorbent packing layer 2. A stirring device 7 is arranged inside the reactor 1 , and the stirring device 7 is arranged below the filter net layer 6 . The regeneration device also includes an operating oil storage device 3 , the oil outlet of the operating oil storage device 3 is connected to the oil inlet of the reactor 1 .

[0056] The bottom of the reactor 1 is provided with an oil outlet 5 , and the oil outlet is located below the filter layer 6 .

[0057] The filter mesh layer 6 can be a metal mesh layer. The operating oil storage device 3 can be an oil storage tank or other devices that can store natural es...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breakdown voltage | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com