Saponification slag recycling method and water-resistant curing agent for recycling

A technology of saponification residue and recycling, which is applied in the field of water-resistant curing agent for recycling, can solve problems such as secondary environmental pollution, and achieve the effects of reducing moisture content, preventing swelling, and being easy to exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

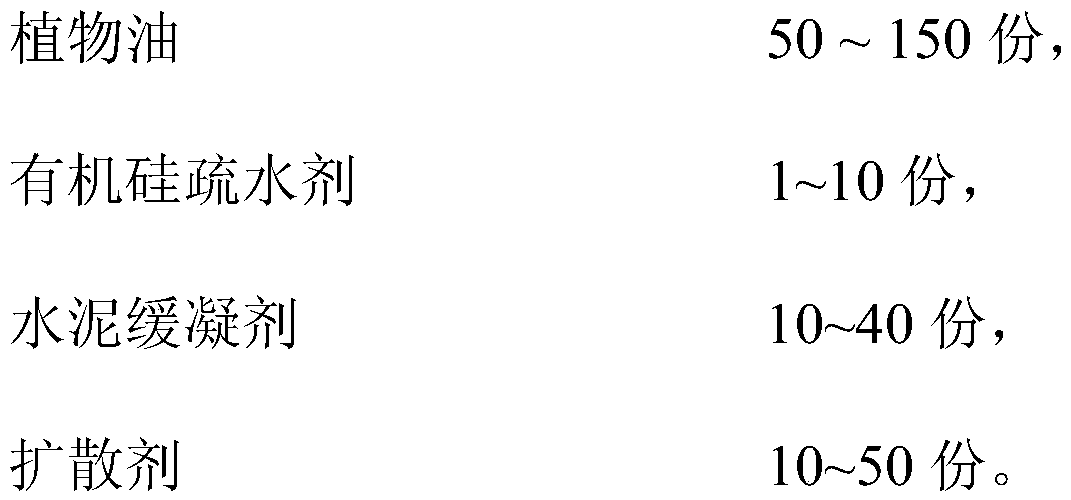

[0048] A water-resistant curing agent for saponification slag recycling, comprising the following components in parts by mass:

[0049] Vegetable oil: mix 20 parts of castor oil, 20 parts of peanut oil, and 10 parts of rapeseed oil;

[0050] Silicone hydrophobic agent: 1 part A151;

[0051] Cement retarder: mix 10 parts of sodium lignosulfonate and 10 parts of CMC;

[0052] Diffuser: 5 parts of EL-20, 2 parts of Span-80, 1 part of sodium linoleate, 1 part of sodium oleate, 1 part of potassium oleate and mix well.

[0053]Under the condition of 50°C, vegetable oil and organosilicon hydrophobizing agent are metered and mixed uniformly to obtain component A; cement retarder and diffusing agent are metered and mixed, and 20% water is added to dilute and stirred uniformly to obtain component B; component A is added dropwise to In component B, keep a constant temperature of 50°C and stir evenly to obtain a water-resistant curing agent for saponification slag recycling.

[0054] A...

Embodiment 2

[0058] A water-resistant curing agent for saponification slag recycling, comprising the following components in parts by mass:

[0059] Vegetable oil: mix 20 parts of castor oil, 30 parts of peanut oil, and 30 parts of rapeseed oil;

[0060] Silicone hydrophobic agent: mix 2 parts of A151 and 3 parts of A171;

[0061] Cement retarder: mix 5 parts of sodium lignosulfonate and 5 parts of CMC;

[0062] Diffuser: 15 parts of EL-20, 5 parts of Span-80, 5 parts of Tween-20, 3 parts of sodium linoleate, 2 parts of sodium oleate and mix well.

[0063] The preparation method of the water-resistant curing agent for saponification slag recycling is the same as in Example 1.

[0064] A method for recycling saponification slag, comprising the following steps:

[0065] S1, pretreatment: mix fly ash and saponified slag B according to the dry weight of 40:60, and dry it in a waterproof stack for 25 days under natural conditions to obtain a saponified slag / fly ash mixture, control the moist...

Embodiment 3

[0068] A water-resistant curing agent for saponification slag recycling, comprising the following components in parts by mass:

[0069] Vegetable oil: mix 50 parts of castor oil, 30 parts of peanut oil, 50 parts of rapeseed oil, and 20 parts of sunflower oil;

[0070] Silicone hydrophobic agent: mix 5 parts A151, 3 parts A171, 2 parts A172;

[0071] Cement retarder: mix 30 parts of sodium lignosulfonate and 10 parts of CMC;

[0072] Diffuser: 15 parts of EL-20, 10 parts of Span-80, 10 parts of Tween-20, 5 parts of sodium linoleate, 5 parts of potassium linoleate, 5 parts of potassium oleate and mix well.

[0073] The preparation method of the water-resistant curing agent for saponification slag recycling is the same as in Example 1.

[0074] A method for recycling saponification slag, comprising the following steps:

[0075] S1, pretreatment: mix fly ash and saponified slag A according to the dry weight of 5:95, and dry it in a waterproof stack for 20 days under natural con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compactness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com