S-doped surface-wrinkled carbon fiber loaded Co and MnO nanoparticles and preparation method and application thereof

A nanoparticle, carbon fiber technology, applied in fiber processing, fiber chemical characteristics, rayon manufacturing and other directions, can solve the problems of carrier corrosion performance, reduction, electrocatalytic performance and stability attenuation, etc., to improve catalytic performance, good electrochemical performance. Effects of stability, high electrocatalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

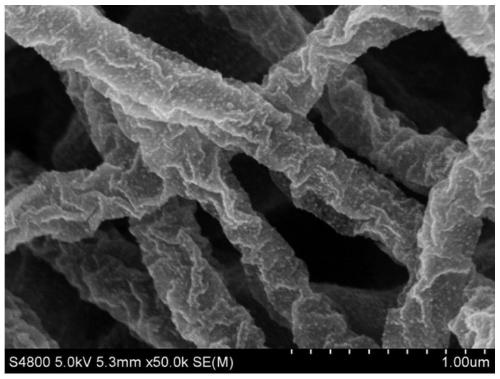

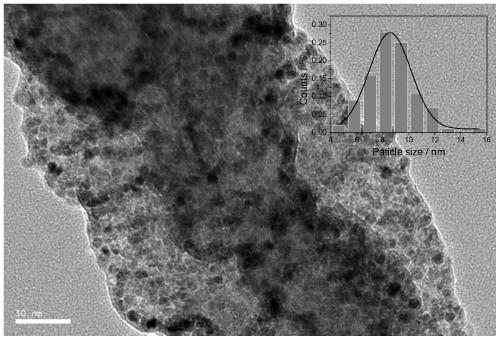

[0034] A preparation method of S-doped surface wrinkled carbon fiber loaded Co and MnO nanoparticles, comprising the following steps:

[0035] 1) Preparation of the spinning polymer precursor solution: Weigh 1.0 g of polyvinylpyrrolidone (PVP), add 13 mL of N,N-dimethylformamide (DMF): ethanol to a mixed solvent of 3:10, and fully stir 12h to make it dissolve; at the same time add 0.582gCo(NO 3 ) 2 ·6H 2 O, 0.245g Mn(Ac) 2 4H 2 O and 10 mg N 2 h 4 CS was stirred for 24h until uniform;

[0036] 2) Preparation of PVP nanofibers containing Co(II) and Mn(II): the dark red solution prepared in step 1) is loaded into the sample tube of the electrospinning instrument, and the needle aperture of the sample tube is 0.6mm. Fix the loaded electrospinning sample tube to receive electrospinning on a flat plate covered with aluminum foil. The working voltage of the electrospinning instrument is 20kV, the curing distance is 15cm, and the injection rate of the electrospinning solution...

Embodiment 2

[0039] Prepare S-doped surface wrinkled carbon fiber loaded Co and MnO nanoparticles according to the same method as in Example 1, the difference is that in this example step 1) Preparation of spinning polymer precursor solution: Weigh 0.5g polyvinylpyrrolidone (PVP), add 13mL N,N-dimethylformamide (DMF): ethanol in the mixed solvent of 3:10, fully stir for 12h to dissolve; add 0.582g Co(NO 3 ) 2 ·6H 2 O, 0.245g Mn(Ac) 2 4H 2 O and 10 mg N 2 h 4 CS was stirred for 24h until homogeneous.

Embodiment 3

[0041] Prepare S-doped surface wrinkled carbon fiber loaded Co and MnO nanoparticles according to the same method as in Example 1, the difference is that in this example step 1) Preparation of spinning polymer precursor solution: Weigh 1.0g of polyvinylpyrrolidone (PVP), add 13mL N,N-dimethylformamide (DMF): ethanol to the mixed solvent of 5:8, fully stir for 12h to make it dissolve; add 0.582g Co(NO 3 ) 2 ·6H 2 O, 0.245g Mn(Ac) 2 4H 2 O and 10 mg N 2 h 4 CS was stirred for 24h until homogeneous.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com