High-efficiency three-dimensional mixing plant

A three-dimensional, mixing plant technology, applied in the direction of dust removal, loading/unloading, and selling raw material supply devices, etc., can solve the problems of low work efficiency, large floor area, and poor safety control, and achieve optimal layout, The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

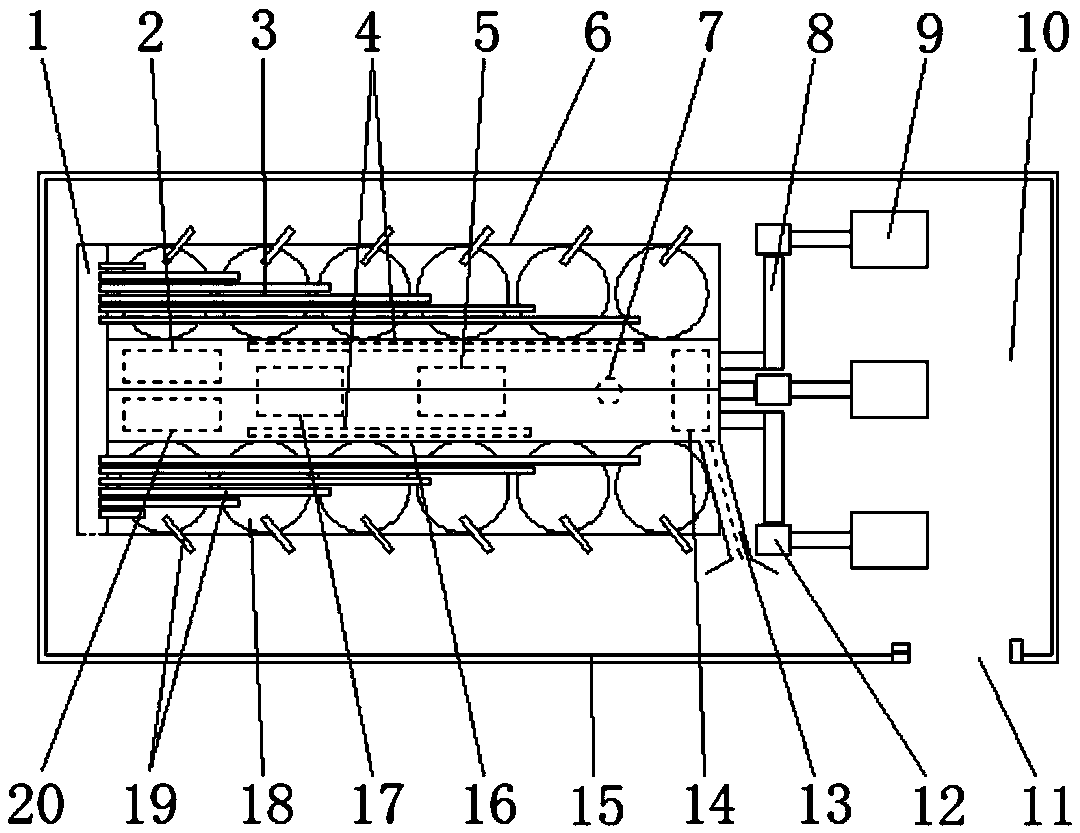

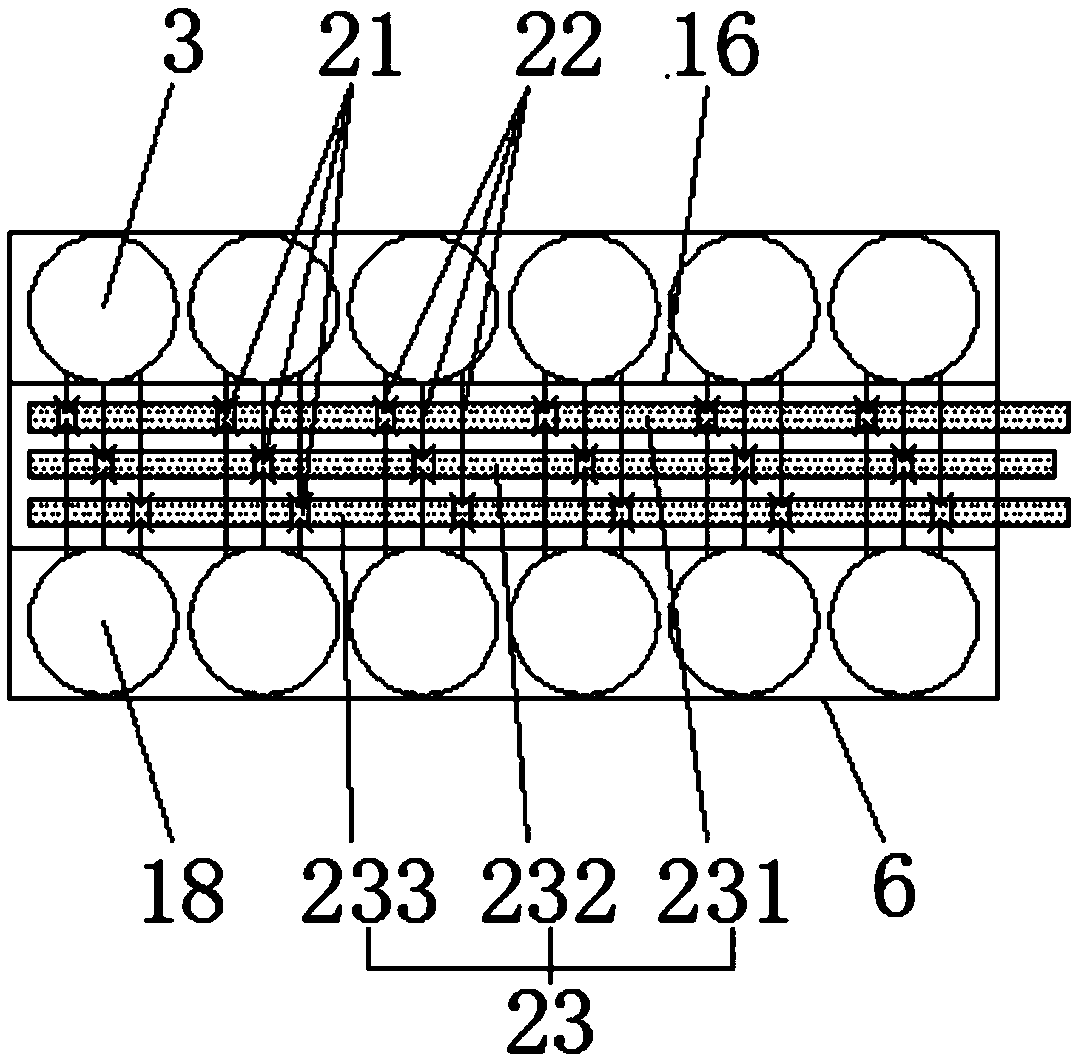

[0029] Such as figure 1 A high-efficiency three-dimensional mixing plant shown includes a production and processing area 6 and three product concentration stations 9 located on the same side of the production and processing area 6. From top to bottom, they are an asphalt station, a water stabilization station and a commercial station. Concrete station, the production and processing area 6 includes a row of raw material bins 3 and a row of recycled material bins 18 oppositely arranged, and the crushing workshop 1 located on the side of the raw material bins 3 and recycled material bins 18 facing away from the product concentration station 9 , and the double-layer factory building 16 of steel structure that is located between the original material bin 3 and the recycled material bin 18, and there is a one-to-one corresponding lifting between the crushing workshop 1 and each original material bin 3 and each recycled material bin 18 The machine 19 is used to transport the material...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is:

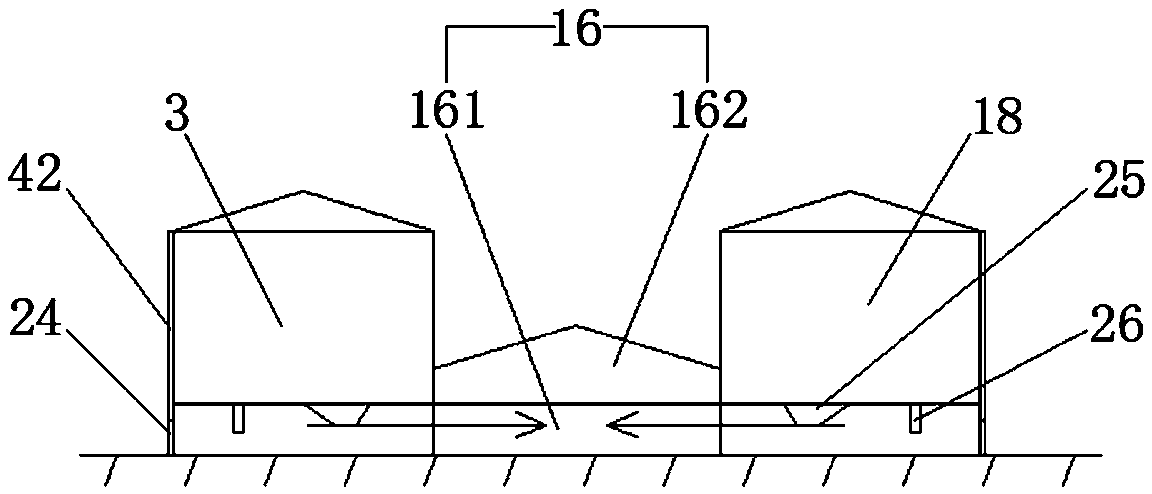

[0037] In this example, if figure 2 , Figure 4 and Image 6 As shown, the lower end of each of the silos 27 faces away from the side of the double-storey factory building 16 and is provided with two loading and unloading openings 26, and the loading and unloading openings 26 are connected with a dust collector 37 and a telescopic barrel 38 , the loading and unloading port 26 is provided with a loading hydraulic valve 36, and the ground directly below the loading and unloading port 26 is provided with a weighbridge 33, and the loading hydraulic valve 36 and the weighbridge 33 are respectively connected with the control electrical connection; the bottom of each of the silos 27 is supported on the ground by fourteen round silo legs 35; the outer sides of the original silos 3 and the regenerated silos 18 are provided with dust-proof walls extending to the ground. Housing 42, and dust-proof housing 42 is prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com